Polymer disperse dye liquid crystal material, electrochromic dimming film and preparation method

A technology of disperse dyes and liquid crystal materials, applied in the field of dimming films, can solve the problems of poor weather resistance, poor product performance, fading, etc., and achieve the effects of good adhesion performance, easy processing into film, and low haze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

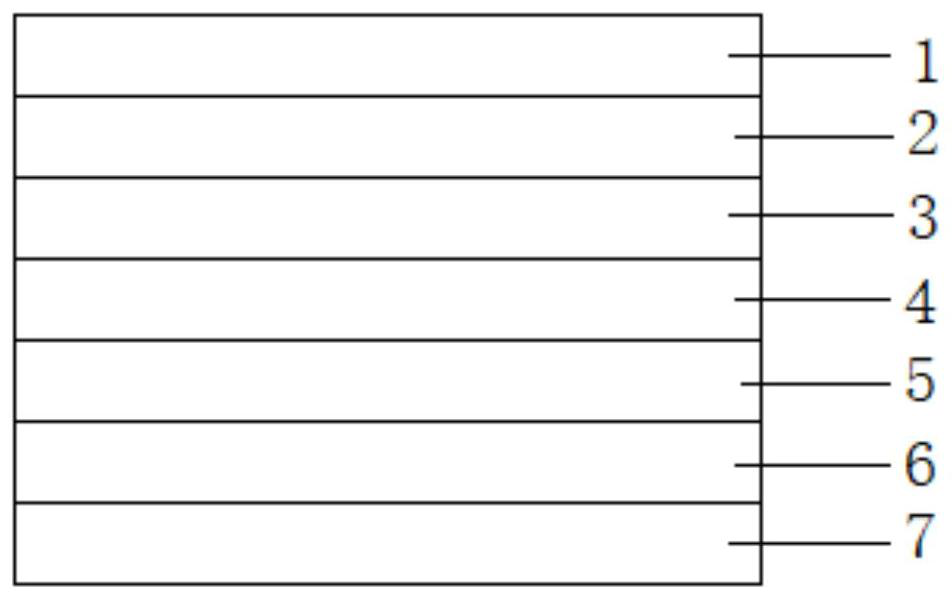

Image

Examples

Embodiment 1

[0040] The electrochromic light-emitting film of this embodiment is prepared through the following steps:

[0041] Step 1: Select a colorless and transparent PET substrate with a thickness of 125 μm, the visible light transmittance of the transparent PET substrate is 89%, and the haze is 0.6%;

[0042] Step 2: Coating an ITO film on a colorless and transparent PET substrate by magnetron sputtering, with a square resistance of 100Ω / □, a visible light transmittance of 82%, and a haze of 0.7%;

[0043] Step 3: Coating an alignment layer on the ITO film, the alignment layer material is polyimide material, the thermal curing temperature is 120°C, the curing time is 5 minutes, and the thickness of the alignment layer after curing is 50nm;

[0044] Step 4: Prepare the dye liquid crystal material, wherein the color of the dye liquid crystal is black, the birefringence Δn is 0.11, the ordinary refractive index no (589nm, 25°C) is 1.478, and the dielectric anisotropy of the liquid cryst...

Embodiment 2

[0066] The electrochromic light-emitting film of this embodiment is prepared through the following steps:

[0067] Step 1: Select a black transparent PET base material with a thickness of 50 μm, the visible light transmittance of the transparent PET base material is 60%, and the haze is 0.9%;

[0068] Step 2: Coating an ITO film on a black transparent PET substrate by magnetron sputtering, with a square resistance of 150Ω / □, a visible light transmittance of 54%, and a haze of 0.9%;

[0069] Step 3: Coating an alignment layer on the ITO film, the alignment layer material is polyimide material, the thermal curing temperature is 100°C, the curing time is 6 minutes, and the thickness of the alignment layer after curing is 10nm;

[0070] Step 4: Prepare the dye liquid crystal material, wherein the color of the dye liquid crystal is black, the birefringence Δn is 0.18, the ordinary refractive index no (589nm, 25°C) is 1.50, and the dielectric anisotropy of the liquid crystal △ε (1KH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com