Trench power device and manufacturing method thereof

A technology for power devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve the problems of limited integration of lithography machines, high relative position requirements, and high lithography alignment requirements. , to achieve the effects of cost controllable, improved integration, and improved device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073]A trench power device and a manufacturing method thereof, including the following steps:

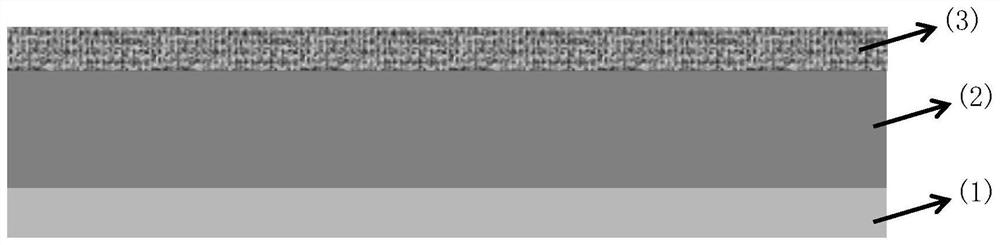

[0074]Step S1, such asfigure 1 As shown, an epitaxial layer 2 is grown on a silicon substrate 1, and the epitaxial layer 2 is grown by chemical weather deposition. The epitaxial layer 2 can be doped with trivalent element boron or pentavalent element arsenic and phosphorus according to the polarity of the device. In this embodiment, trivalent element boron can be doped. The epitaxial layer 2 can have a micron-level change in thickness or adopt a multilayer structure according to the working voltage.

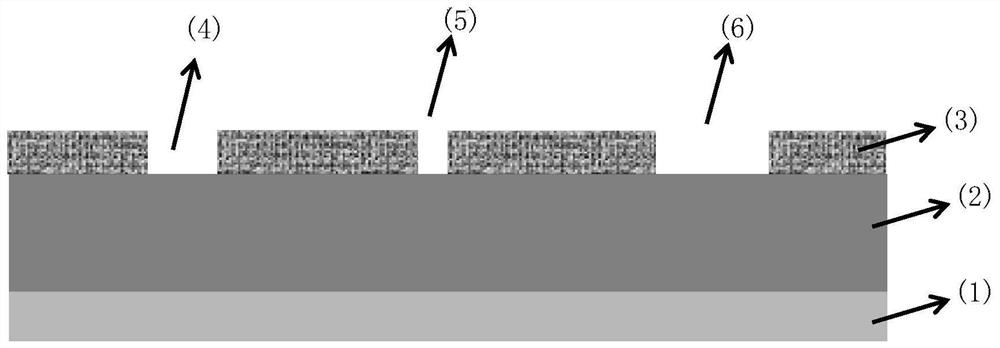

[0075]Step S2, such asfigure 2 As shown, the mask 3 used to form the trench is deposited next. The mask 3 may be a photoresist or a multilayer combined structure of photoresist and other insulator masks. Such as: silicon dioxide-silicon nitride-silicon dioxide. Silicon dioxide and silicon nitride are prepared by chemical weather deposition process; photoresist is spin-coated by photolithography p...

Embodiment 2

[0098]A trench power device and a manufacturing method thereof, including the following steps:

[0099]Step S1, such asfigure 1 As shown, an epitaxial layer 2 is grown on a silicon substrate 1, and the epitaxial layer 2 is grown by chemical weather deposition. The epitaxial layer 2 can be doped with trivalent element boron or pentavalent element arsenic and phosphorus according to the polarity of the device. In this embodiment, pentavalent element arsenic can be doped. The epitaxial layer 2 can have a micron-level change in thickness or adopt a multilayer structure according to the working voltage.

[0100]Step S2, such asfigure 2 As shown, the mask 3 used to form the trench is deposited next. The mask 3 may be a photoresist or a multilayer combined structure of photoresist and other insulator masks. Such as: silicon dioxide-silicon nitride-silicon dioxide. Silicon dioxide and silicon nitride are prepared by chemical weather deposition process; photoresist is spin-coated by photolithograp...

Embodiment 3

[0123]A trench power device and a manufacturing method thereof, including the following steps:

[0124]Step S1, such asfigure 1 As shown, an epitaxial layer 2 is grown on a silicon substrate 1, and the epitaxial layer 2 is grown by chemical weather deposition. The epitaxial layer 2 can be doped with trivalent element boron or pentavalent element arsenic and phosphorus according to the polarity of the device. In this embodiment, pentavalent element phosphorus is doped. The epitaxial layer 2 can have a micron-level change in thickness or adopt a multilayer structure according to the working voltage.

[0125]Step S2, such asfigure 2 As shown, the mask 3 used to form the trench is deposited next. The mask 3 may be a photoresist or a multilayer combined structure of photoresist and other insulator masks. Such as: silicon dioxide-silicon nitride-silicon dioxide. Silicon dioxide and silicon nitride are prepared by chemical weather deposition process; photoresist is spin-coated by photolithograph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com