Purification method for progesterone

A purification method and progesterone technology, which is applied in the purification of progesterone crude product and the field of progesterone purification, can solve the problems that it is difficult to produce qualified progesterone raw material medicine and reduce it to below 0.6%, and achieve good economic and social benefits , low equipment requirements, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

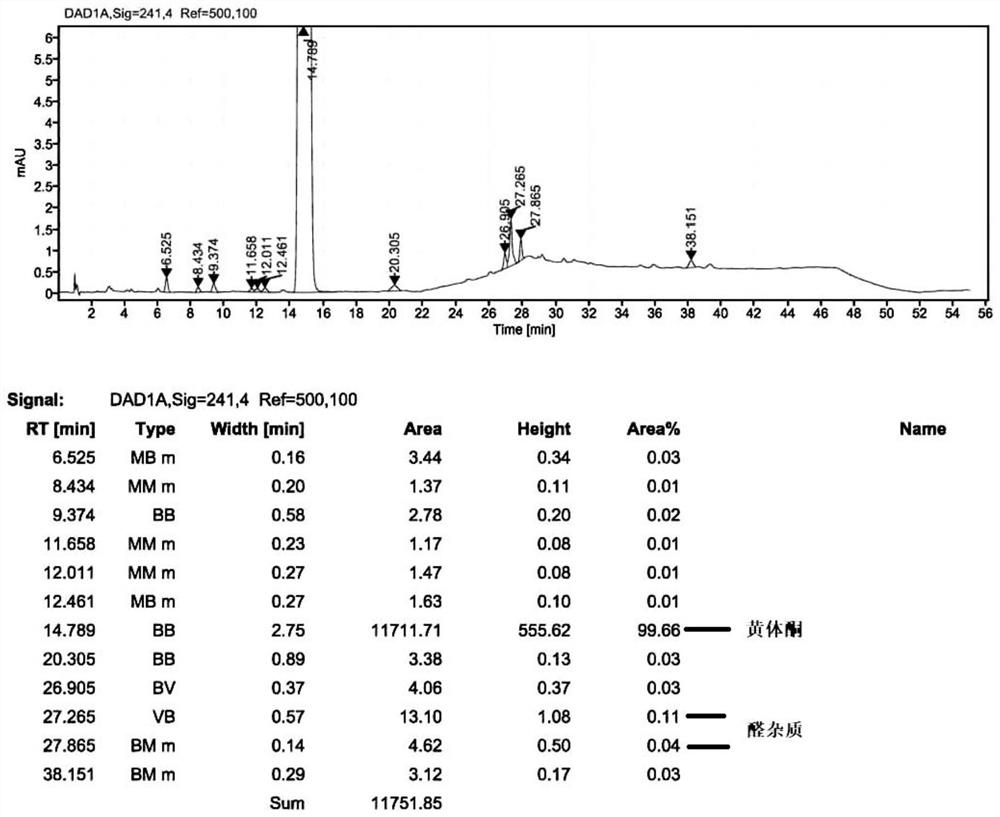

[0041] The high-purity purification method of example 1 progesterone

[0042] Put 50g of crude progesterone (containing 2% impurity aldehyde) into 50ml of ethanol, add 2.5ml of 40% sodium metabisulfite aqueous solution, control 60°C to stir and react for 1 hour after completely dissolving, cool to 5°C, and obtain a preliminary reaction treatment product.

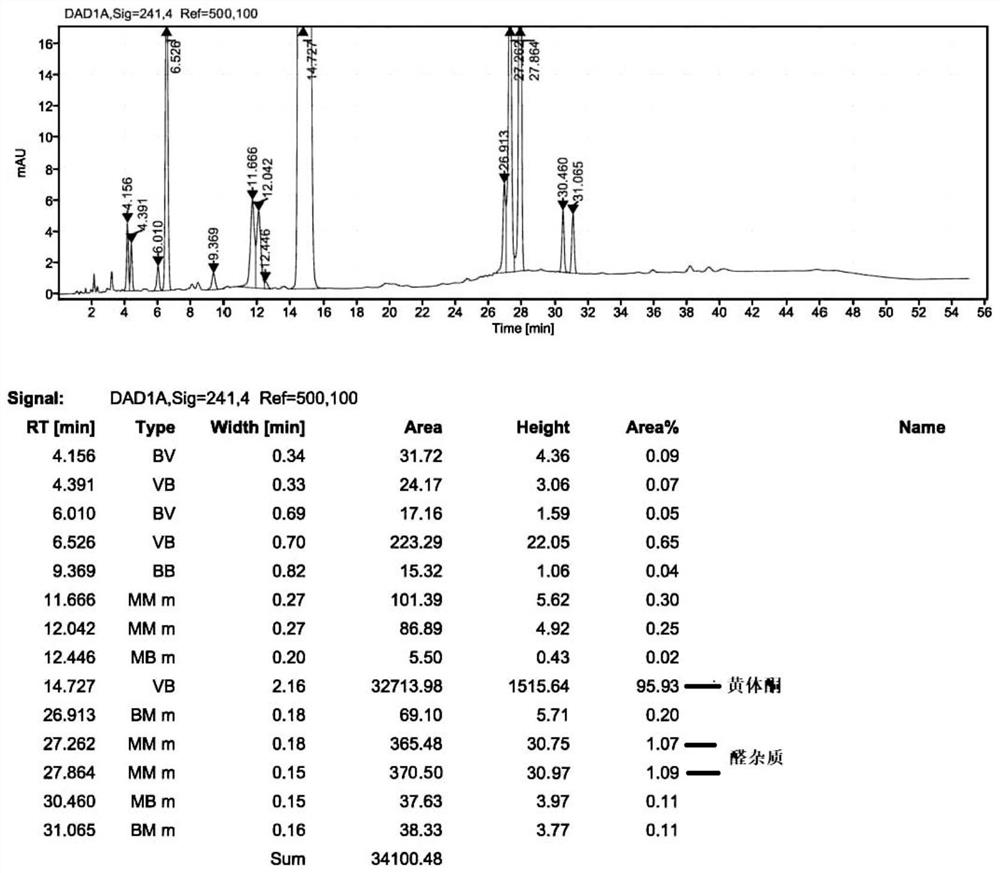

[0043] Add 25ml of water to the preliminary reaction product, filter, wash the filter cake with water until neutral, and dry to obtain 47.8g of progesterone fine product, the product yield is 95.6%, the product melting point is 129.0-130.0°C, the HPLC content is 99.6%, and the impurity aldehyde figure 2 mentioned.

[0044] The high performance liquid chromatogram of this progesterone crude product is as follows figure 1 shown.

example 2

[0045] The high-purity purification method of example 2 progesterone

[0046] Put 50g of crude progesterone (containing 3% impurity aldehyde) into 350ml of isopropanol, add 25ml of 20% potassium bisulfite aqueous solution, completely dissolve, control 40°C to stir and react for 0.1 hour, cool down to -5°C, and obtain the preliminary reaction treatment product .

[0047] Add 150ml of water to the preliminary reaction product, filter, wash the filter cake until neutral, and dry to obtain 47.6g of progesterone fine product, the product yield is 95.2%, the product melting point is 129.1-130.0°C, the HPLC content is 99.5%, and the impurity aldehyde is <0.2% .

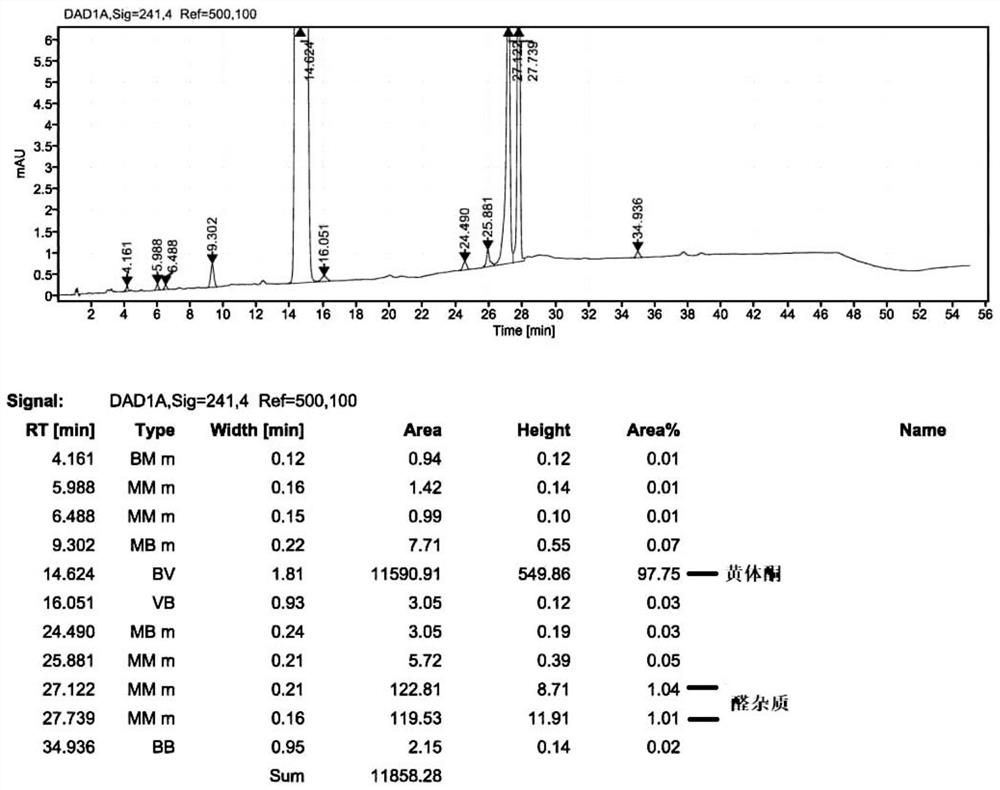

example 3

[0048] The high-purity purification method of example 3 progesterone

[0049] Put 50g of progesterone crude product (containing 3% impurity aldehyde) into 750ml of tert-butanol, add 50ml of 5% potassium metabisulfite aqueous solution, control 20°C to stir and react for 2 hours after completely dissolving, cool down to -20°C, and obtain the preliminary reaction treatment product .

[0050] Add 250ml of water to the preliminary reaction product, filter, wash the filter cake until neutral, and dry to obtain 47.5g of progesterone fine product, the product yield is 95.0%, the product melting point is 129.1-130.2°C, the HPLC content is 99.6%, and the impurity aldehyde <0.15% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com