Method for improving performance of Bi-Sb-Te-based thermoelectric material

A technology of bi-sb-te and thermoelectric materials, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of limited application range and poor thermoelectric performance, and achieve high application value , optimized electrical transport properties, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for improving the performance of Bi-Sb-Te-based thermoelectric materials, comprising the following steps:

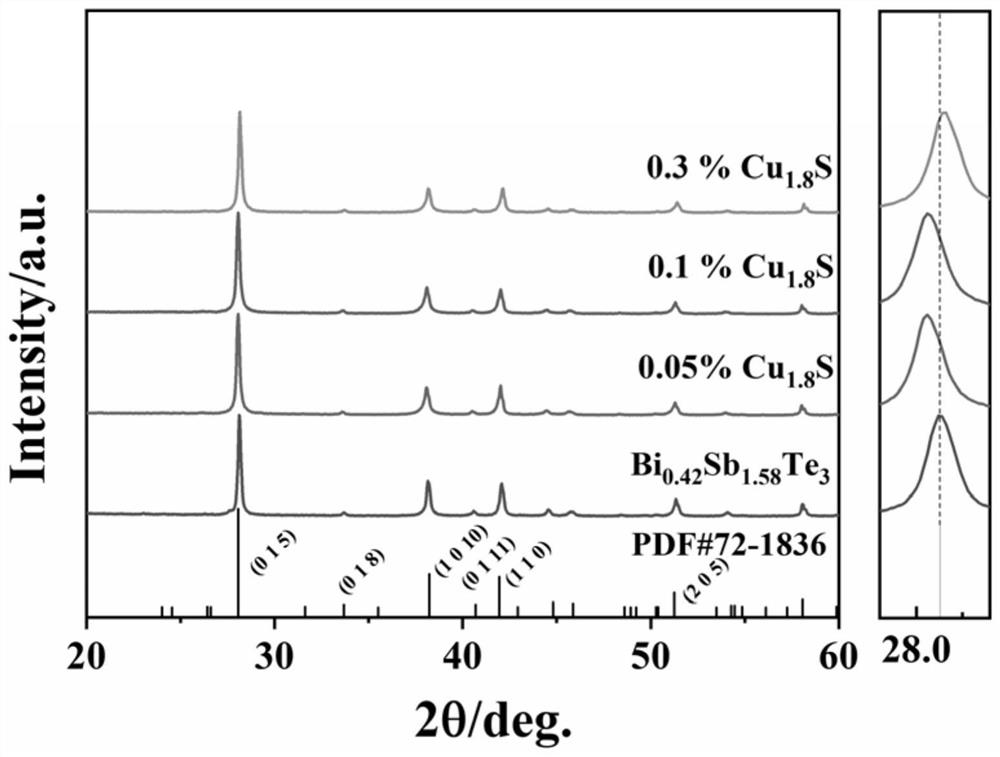

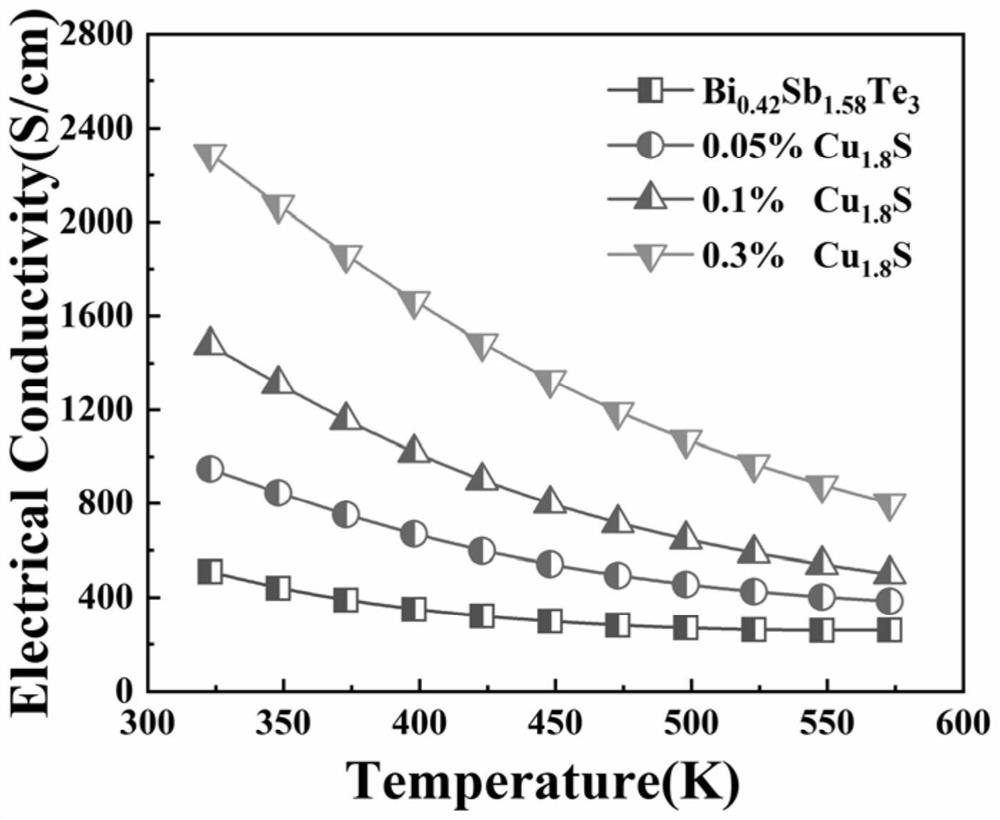

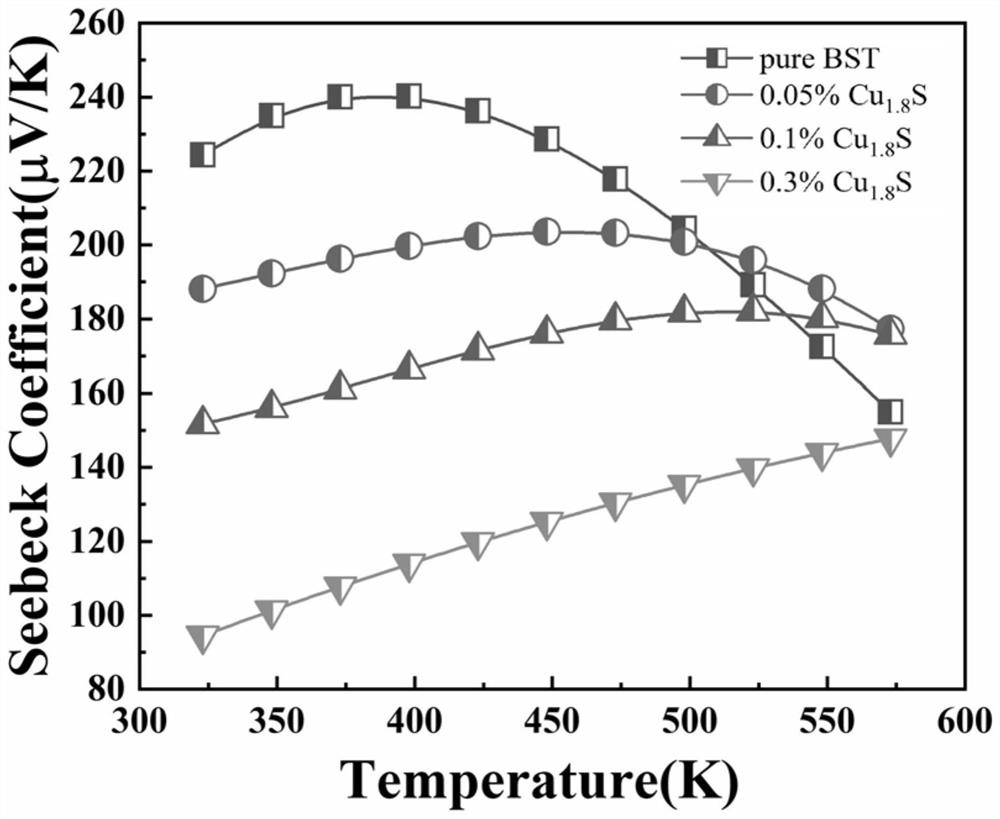

[0042] Step 1: In a glove box filled with an argon protective atmosphere, put Te grains, Sb grains, Bi powder and Cu powders with a purity of not less than 99.99% (mass fraction) 1.8 S powder, according to the general chemical formula is Bi 0.42 Sb 1.58 Te 3 (Cu 1.8 S) x Weigh each component (total mass is 16g), wherein x is 0.3%, put into the quartz tube and vacuumize, keep the absolute vacuum degree less than 10 after vacuum -4 Pa, encapsulated with oxyhydrogen flame.

[0043] Step 2: Place the quartz tube in step 1 in a vertical tube furnace and heat it from room temperature to 650 °C at a heating rate of 100 °C per hour, keep it warm for 5 hours, and then raise the temperature of the quartz tube from 650 °C to 950 °C at the same heating rate ℃ for 16 hours, and then cooled with the furnace to obtain the initial ingot.

[0044]Step 3: Put the in...

Embodiment 2~3

[0047] The difference from Example 1 is that Cu 1.8 The content of S is different, wherein x=0.05% in embodiment 2; x=0.1% in embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com