Preparation method of silicon nanosheet array

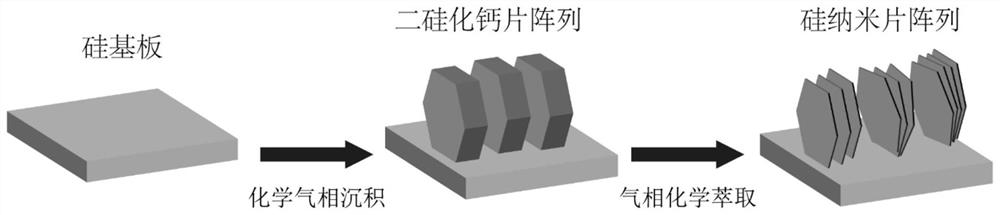

A technology for silicon nanosheets and arrays is applied in the field of preparation of silicon nanosheet arrays, which can solve the problems of low density and uncontrollable morphology, and achieve the effects of uniform size, reduction of dangling bonds and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

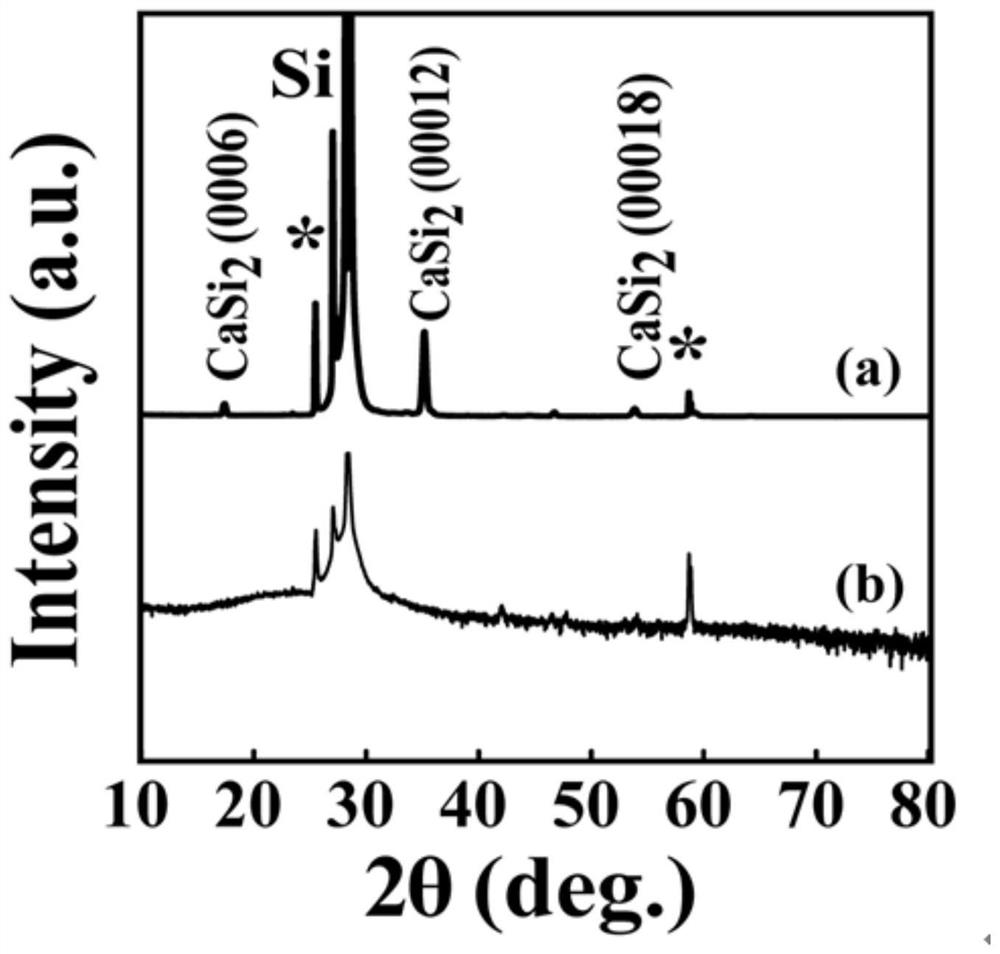

[0033] A method for preparing a silicon nanosheet array, carried out as follows:

[0034] (1) Silicon substrate pretreatment

[0035] Set the size to 8*8mm 2 , a thickness of about 1 mm, and a single crystal silicon substrate with a crystal plane of (111) was soaked in 50 mL of acetone solution for ultrasonication, and then evaporated to the remaining 15 mL of acetone solution. : Soak in the mixed solution formed by the volume ratio of 1:2 for 10 seconds, rinse with pure water, and finally dip it in an aqueous solution of hydrofluoric acid with a volume fraction of 8% for cleaning, and dry it in the air after washing;

[0036] (2) Preparation of silicide precursor

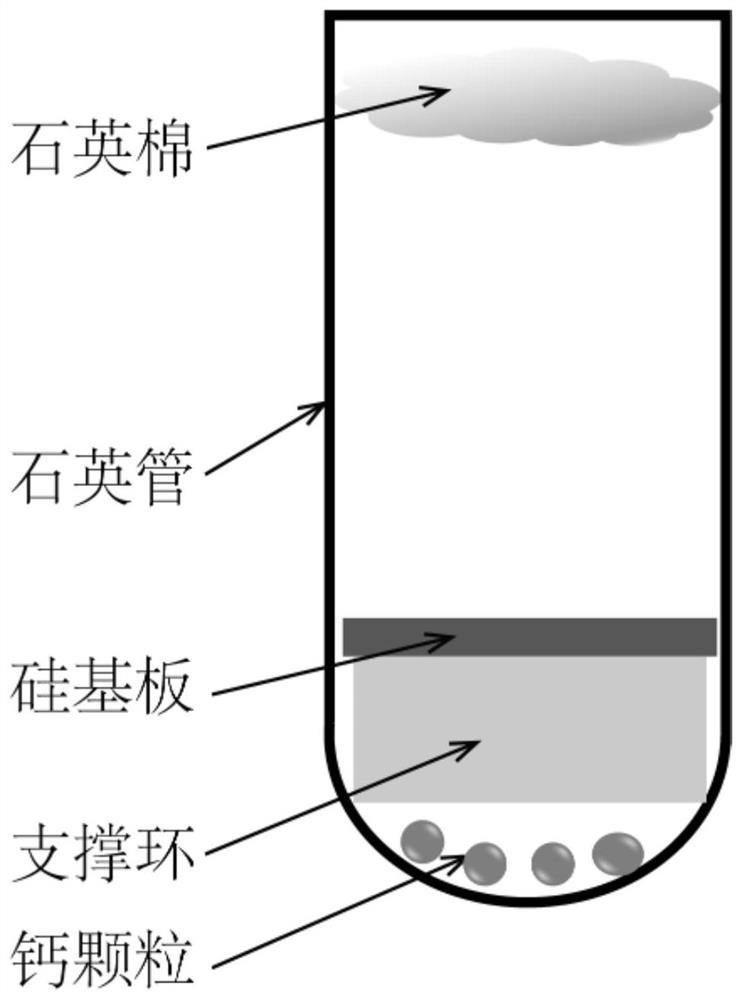

[0037] Place the pretreated silicon substrate and 0.025g of calcium metal particles in an adaptation container, the calcium metal particles are at the bottom of the quartz container, the silicon substrate is at the upper end of the calcium metal particles, and keep a certain distance, face down, and use the quart...

Embodiment 2

[0044] A method for preparing a silicon nanosheet array, carried out as follows:

[0045] (1) Silicon substrate pretreatment

[0046] Set the size to 8*8mm 2 , a thickness of about 1 mm, and a single crystal silicon substrate with a crystal plane of (111) was soaked in 50 mL of acetone solution for ultrasonication, and then evaporated to the remaining 15 mL of acetone solution. : Soak in the mixed solution formed by the volume ratio of 1:2 for 10 seconds, rinse with pure water, and finally dip it in a hydrofluoric acid aqueous solution with a volume fraction of 10%, and dry it in the air after washing;

[0047] (2) Preparation of silicide precursor

[0048] Place the silicon substrate and 0.03g of calcium metal particles in an adaptation container, the calcium metal particles are at the bottom of the quartz container, the silicon substrate is at the upper end of the calcium metal particles, and keep a certain distance, face down, and the quartz container mouth is sealed with...

Embodiment 3

[0055] A method for preparing a silicon nanosheet array, carried out as follows:

[0056] (1) Silicon substrate pretreatment

[0057] Set the size to 8*8mm 2 , a thickness of about 1 mm, and a single crystal silicon substrate with a crystal plane of (111) was soaked in 50 mL of acetone solution for ultrasonication, and then evaporated to the remaining 15 mL of acetone solution. : Soak in the mixed solution formed by the volume ratio of 1:2 for 10 seconds, rinse with pure water, and finally dip it with a hydrofluoric acid aqueous solution with a volume fraction of 5% for cleaning, and dry it in the air after washing;

[0058] (2) Preparation of silicide precursor

[0059] Place the silicon substrate and 0.02g of calcium metal particles in an adaptation container, the calcium metal particles are at the bottom of the quartz container, the silicon substrate is at the upper end of the calcium metal particles, and keep a certain distance, face down, and the quartz container mouth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com