FA pretreatment-based enhanced synchronous short-cut denitrification anaerobic ammonia oxidation coupled in-situ fermentation deep denitrification device and method thereof

An anaerobic ammonium oxidation and short-range denitrification technology, which is applied in the field of sewage biological treatment, can solve the problems that short-range denitrifying microorganisms are difficult to directly utilize complex organic matter, insufficient high-quality electron donors, and long hydraulic retention time, so as to shorten hydraulic retention time. , The effect of saving sludge disposal costs and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific example the present invention is described in further detail:

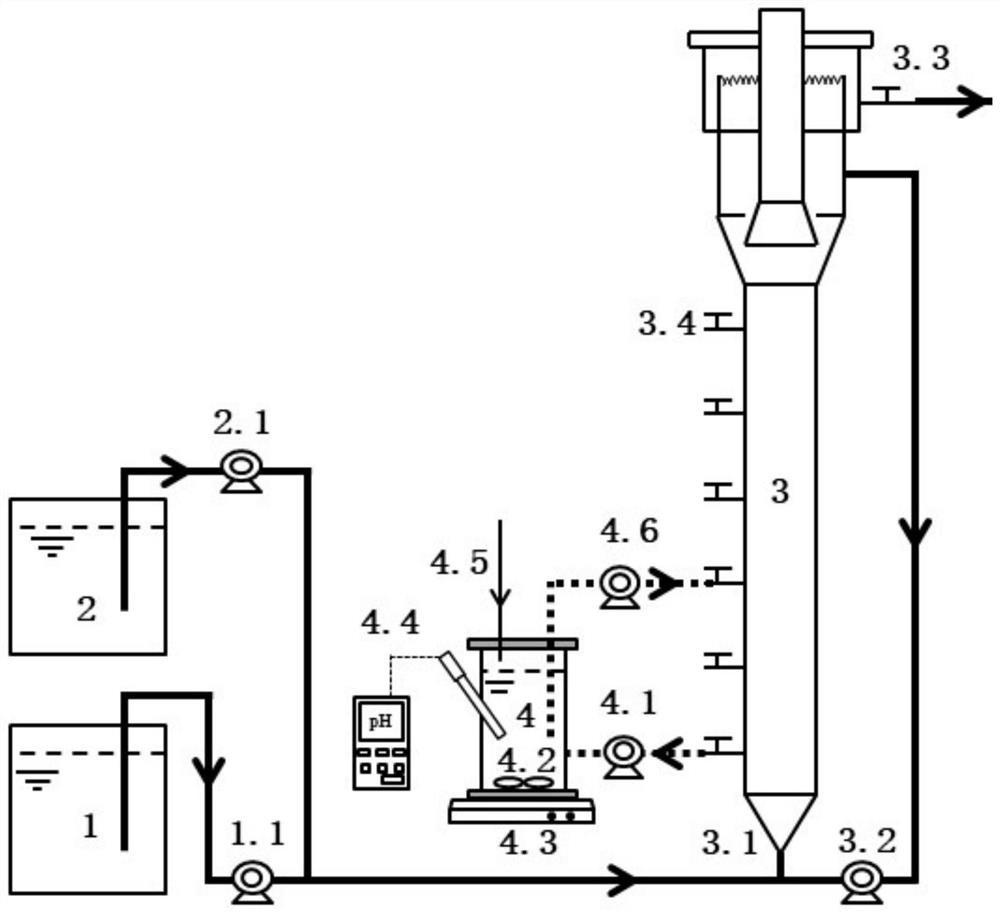

[0024] Such as figure 1 As shown, a device based on FA pretreatment to strengthen synchronous short-range denitrification anammox combined with in-situ fermentation deep nitrogen removal device, including: domestic sewage tank 1, nitrate waste water tank 2, short-range denitrification / anammox / raw Fermentation reactor 3, sludge pretreatment reactor 4. The short-range denitrification / anammox / in-situ fermentation reactor 3 is provided with a water inlet 3.1, a reflux pump 3.2, a water outlet 3.3, and a valve 3.4; the sludge pretreatment reactor 4 is provided with a stirrer 4.2, a magnetic Stirrer 4.3, pH online measuring instrument 4.4, dosing tube 4.5. The domestic sewage tank 1 is connected to the water inlet 3.1 of the short-range denitrification / anammox / in-situ fermentation reactor through the inlet pump I1.1; the nitrate waste water tank 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com