Low-VOC semi-water-based heavy oil stain cleaning agent

A heavy oil cleaning agent, semi-water-based technology, applied in the field of cleaning agents, can solve the problems of skin corrosion, human health and environmental impact, safety, etc., to enhance the solubility, avoid volatile and flammable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

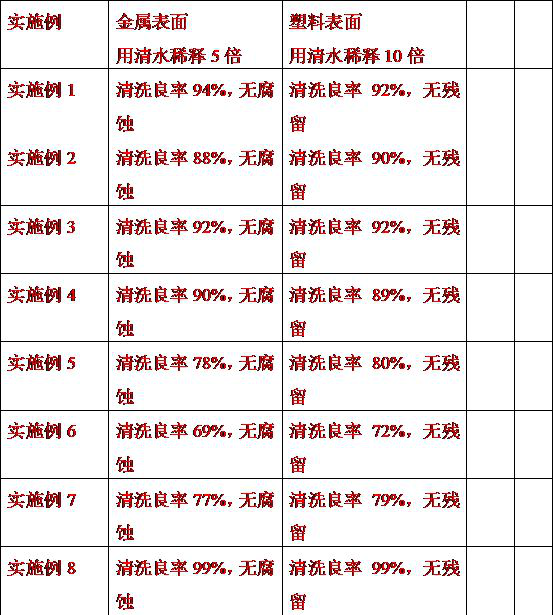

Examples

Embodiment 1

[0017] Low-VOC semi-water-based heavy oil cleaning agent, the composition (mass percentage) of the cleaning agent is 0.5% ethylenediaminetetraacetic acid, 0.6% alkylphenol polyoxyethylene ether, 0.5% diethanolamine, EDTA-2 sodium 0.1%, diethylene glycol butyl ether solvent 5%, sodium citrate 8%, and the balance is deionized water.

Embodiment 2

[0019] Low-VOC semi-water-based heavy oil stain cleaning agent, the composition (mass percentage) of the cleaning agent is 1% sodium gluconate, 0.6% fatty alcohol polyoxyethylene ether sodium sulfate, 0.1% alkylphenol polyoxyethylene ether, Triethanolamine 3%, EDTA-4 sodium 0.1%, ethylene glycol butyl ether solvent 2%, sodium gluconate 12%, and the balance is deionized water.

Embodiment 3

[0021] Low-VOC semi-water-based heavy oil stain cleaning agent, the composition (mass percentage) of the cleaning agent is 0.5% ethylenediaminetetraacetic acid, 2% sodium gluconate, 0.6% alkylphenol polyoxyethylene ether, isopropanol Amine 3%, EDTA-2 sodium 0.3%, diethylene glycol butyl ether solvent 3%, sodium carbonate 5%, and the balance is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com