Surface passivation structure for III-V group nitride device and device thereof

A nitride and device technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as current density drop, devices cannot be completely turned on, and negative charges cannot be released in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

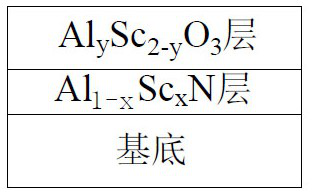

[0027] Such as figure 1As shown, a surface passivation structure for III-V nitride devices, including Al 0.2 sc 0.8 N layer and AlScO 3 layer, where Al 0.2 sc 0.8 The thickness of N layer is 1nm, AlScO 3 The thickness of the layer is 1 nm.

[0028] The specific production method is as follows: Step 1: Control the operating chamber of the atomic layer deposition system at 425°C, and after the substrate temperature is stable, inject trimethylaluminum (0.2s) and ammonia (0.5 s), trimethylaluminum (0.2s), triisopropylcyclopentadienyl scandium (2s), after 8 cycles, a 1.0nm thin layer of aluminum scandium nitride (Al 0.2 sc 0.8 N). Step 2: Cool down the operating chamber of the atomic layer deposition system and control it at 300°C, and after the substrate temperature is stable, pass in trimethylaluminum (0.2s), deionized water (0.5s), three Methyl aluminum (0.2s), triisopropylcyclopentadienyl scandium (2s), after 5 cycles, a 1.0nm thin layer of aluminum scandium oxide (AlS...

Embodiment 2

[0030] A surface passivation structure for III-V nitride devices, comprising Al 0.2 sc 0.8 N layer and AlScO 3 layer, where Al 0.2 sc 0.8 The thickness of N layer is 0.5nm, AlScO 3 The thickness of the layer is 2 nm.

[0031] The specific production method is as follows: Step 1: Control the operating chamber of the atomic layer deposition system at 425°C, and after the substrate temperature is stable, inject trimethylaluminum (0.2s) and ammonia (0.5 s), trimethylaluminum (0.2s), triisopropylcyclopentadienyl scandium (2s), after 8 cycles, a 1.0nm thin layer of aluminum scandium nitride (Al 0.2 sc 0.8 N). Step 2: Cool down the operating chamber of the atomic layer deposition system and control it at 300°C, and after the substrate temperature is stable, pass in trimethylaluminum (0.2s), deionized water (0.5s), three Methyl aluminum (0.2s), triisopropylcyclopentadienyl scandium (2s), after 10 cycles, a 2.0nm thin layer of aluminum scandium oxide (AlScO) can be deposited on...

Embodiment 3

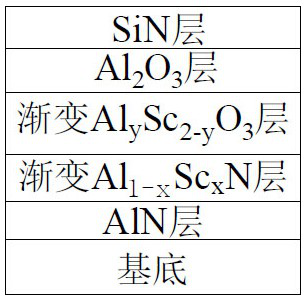

[0033] Such as figure 2 As shown, a surface passivation structure for III-V nitride devices, including AlN layer, Al 0.2 sc 0.8 N layer, Al 0.6 sc 0.4 N layer, Al 1.2 sc 0.8 o 3 layer, AlScO 3 layer. Among them, the thickness of AlN layer is 0.3nm, Al 0.2 sc 0.8 The thickness of N layer is 0.3nm, Al 0.6 sc 0.4 The thickness of N layer is 0.4nm, Al 1.2 sc 0.8 o 3 layer thickness of 0.5nm, AlScO 3 The thickness of the layer is 1nm, Al 2 o 3 The thickness of the layer is 0.5 nm.

[0034] In this example, Al 1-x sc x The N layer is specifically composed of Al 0.2 sc 0.8 N layer and Al 0.6 sc 0.4 N layers, the content of Al in each layer increases from bottom to top, and the content of Sc decreases from bottom to top. Al y sc 2-y o 3 Al 1.2 sc 0.8 o 3 layer and AlScO 3 Layers, the Al content in each layer decreases from bottom to top, and the Sc content increases from bottom to top. Gradient Al 1-x sc x N layer and graded Al y sc 2-y o 3 The la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com