Preparation method of heterojunction photoelectric detector based on single-walled carbon nanotube film

A technology of single-wall carbon nanotubes and photodetectors, applied in the field of photodetectors, can solve the problems of high dark current, poor detection performance, high cost, etc., and achieve the effects of fast response, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

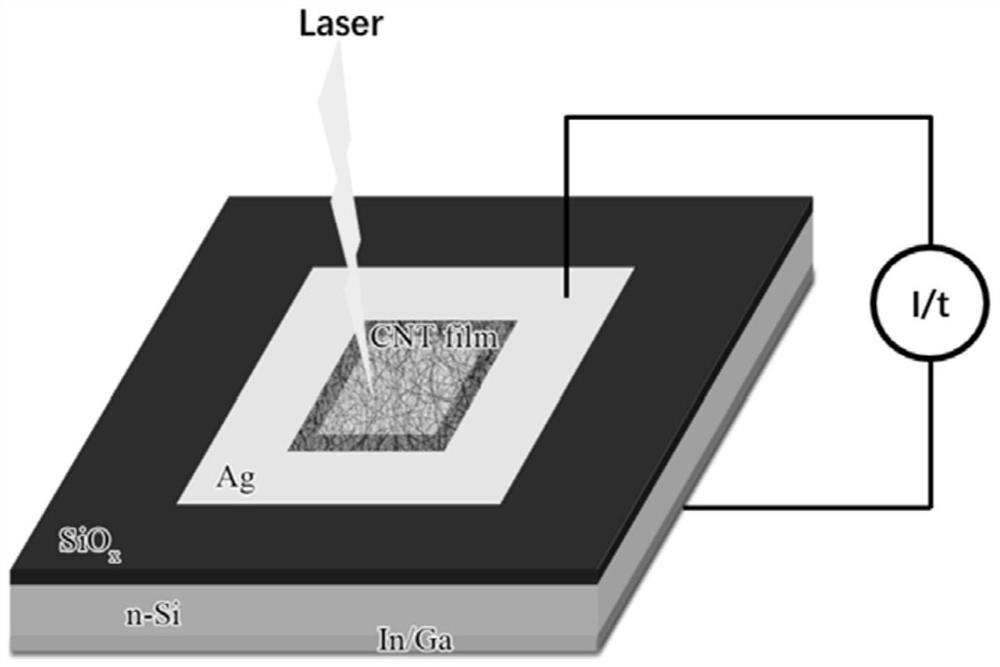

[0035] In this embodiment, the preparation method of a heterojunction photodetector based on a single-walled carbon nanotube film includes the following steps:

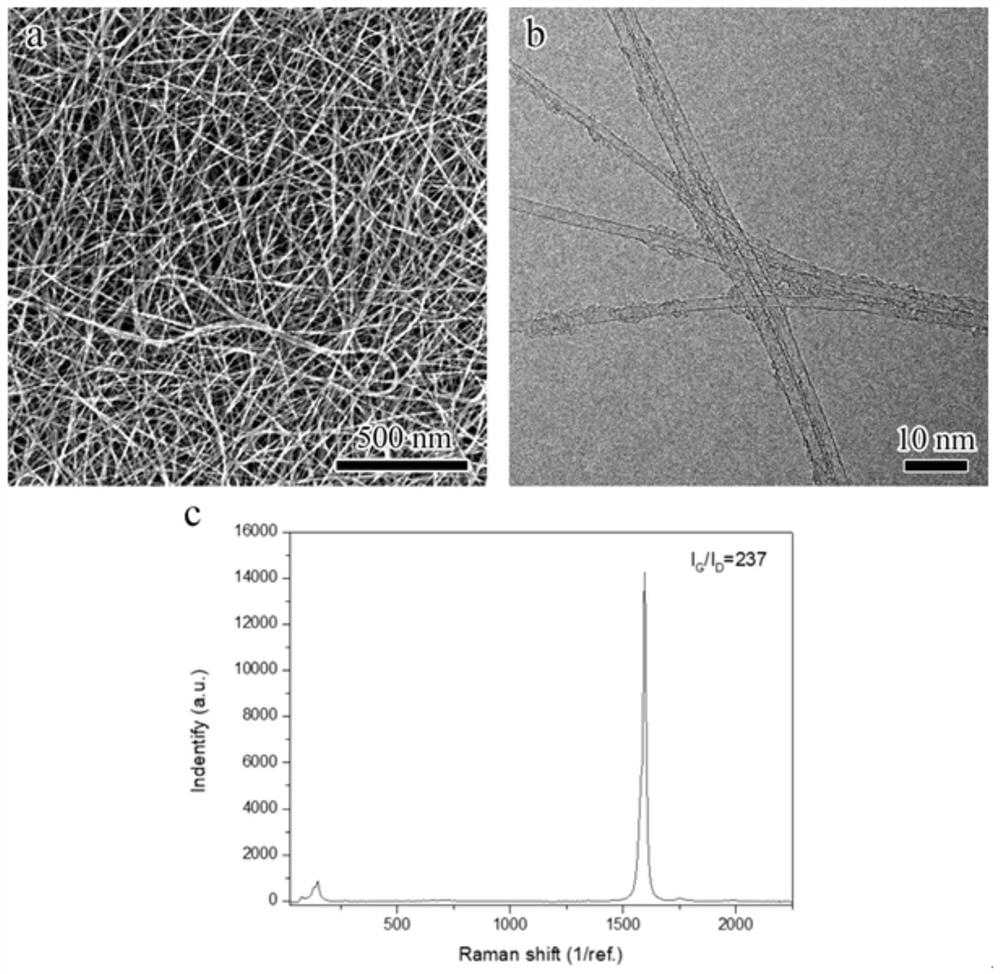

[0036] Step 1. Prepare a high-performance single-walled carbon nanotube film by floating catalyst chemical vapor deposition, grow single-walled carbon nanotubes under optimized conditions, and adjust the collection time to obtain a light transmittance range of 85% and a surface resistance of 110Ω / The single-walled carbon nanotube film of (sheet resistance), the single-walled carbon nanotube film deposited on the microporous membrane (in this embodiment, using a water-based microporous membrane with a pore size of 0.45 μm) is cut into a suitable size .

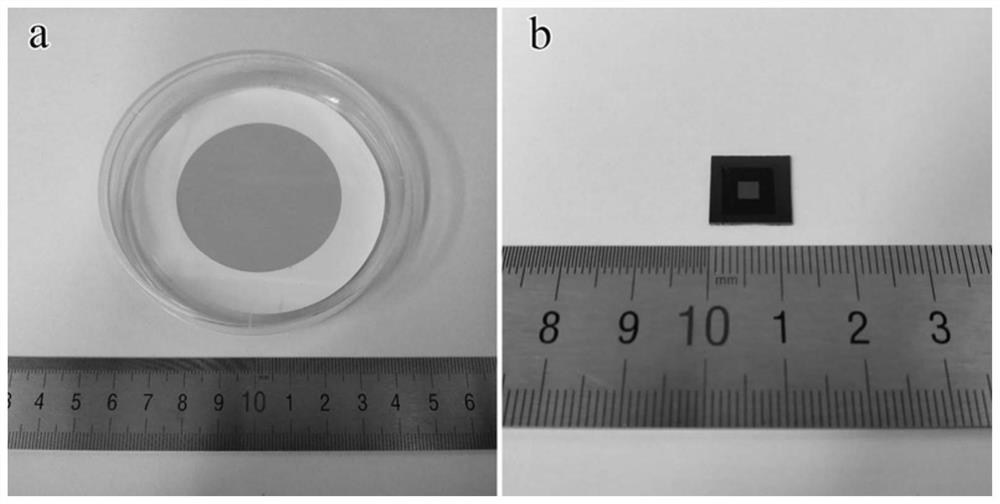

[0037] Step 2. Cut out an N-type silicon wafer with an area of 1.2cm×1.2cm and a thickness of 400μm (resistivity 0.05~0.2Ω·cm, with a silicon oxide layer with a thickness of 300nm), and first stick insulating tape on the silicon substrate On the upper surface, use ...

Embodiment 2

[0042] In this embodiment, the preparation method of a heterojunction photodetector based on a single-walled carbon nanotube film includes the following steps:

[0043] Step 1. Prepare a high-performance single-walled carbon nanotube film by floating catalyst chemical vapor deposition, grow single-walled carbon nanotubes under optimized conditions, and adjust the collection time to obtain a light transmittance range of 92% and a surface resistance of 500Ω / The single-walled carbon nanotube film of (sheet resistance), the single-walled carbon nanotube film deposited on the microporous membrane (in this embodiment, using a water-based microporous membrane with a pore size of 0.45 μm) is cut into a suitable size .

[0044] Step 2. Cut out an N-type silicon wafer with an area of 1.2cm×1.2cm and a thickness of 400μm (resistivity 0.05~0.2Ω·cm, with a silicon oxide layer with a thickness of 300nm), and first stick insulating tape on the silicon substrate On the upper surface, use ...

Embodiment 3

[0049] In this embodiment, the preparation method of a heterojunction photodetector based on a single-walled carbon nanotube film includes the following steps:

[0050] Step 1. Prepare a high-performance single-walled carbon nanotube film by floating catalyst chemical vapor deposition, grow single-walled carbon nanotubes under optimized conditions, and adjust the collection time to obtain a light transmittance range of 70% and a surface resistance of 60Ω / The single-walled carbon nanotube film of (sheet resistance), the single-walled carbon nanotube film deposited on the microporous membrane (in this embodiment, using a water-based microporous membrane with a pore size of 0.45 μm) is cut into a suitable size .

[0051] Step 2. Cut out an N-type silicon wafer with an area of 1.2cm×1.2cm and a thickness of 400μm (resistivity 0.05~0.2Ω·cm, with a silicon oxide layer with a thickness of 300nm), and first stick insulating tape on the silicon substrate On the upper surface, use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com