High-rate lithium iron phosphate battery and preparation method thereof

A lithium iron phosphate battery, high-rate technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve safety problems, limit the rate performance of lithium iron phosphate batteries, and the decomposition of positive electrode materials, so as to improve capacity and energy density , good electronic conductivity, and the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of a high-rate lithium iron phosphate battery, the method comprising the following steps:

[0054] S1: Making pole pieces:

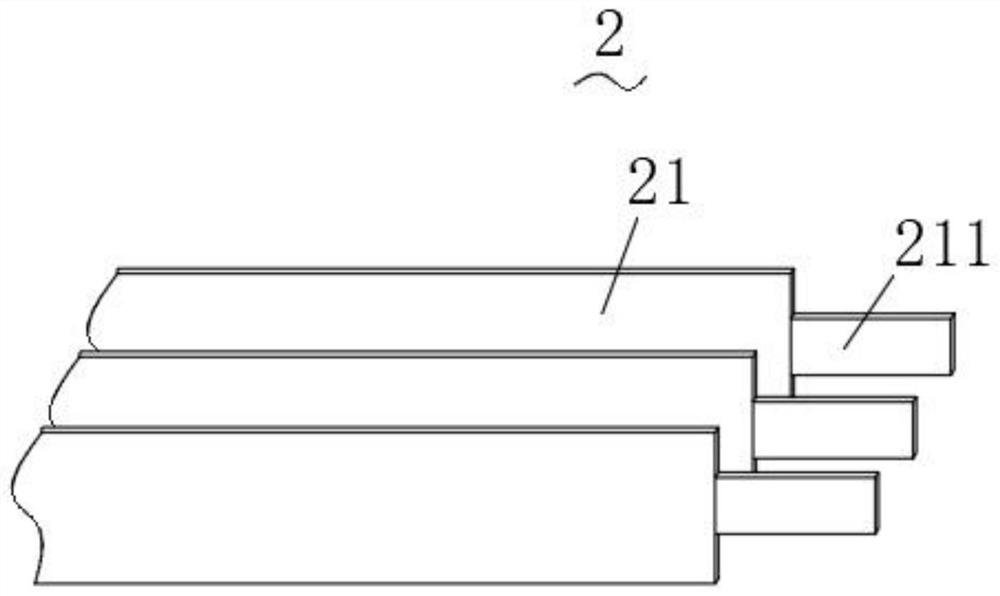

[0055] Including the production of positive pole pieces:

[0056] Mix the active material, conductive agent and dispersant, then add the solvent to obtain the positive electrode slurry, and keep the solid content at 50-70%; then coat the positive electrode material on the surface of the positive electrode substrate, dry, roll, and cut Afterwards, the positive pole piece is obtained;

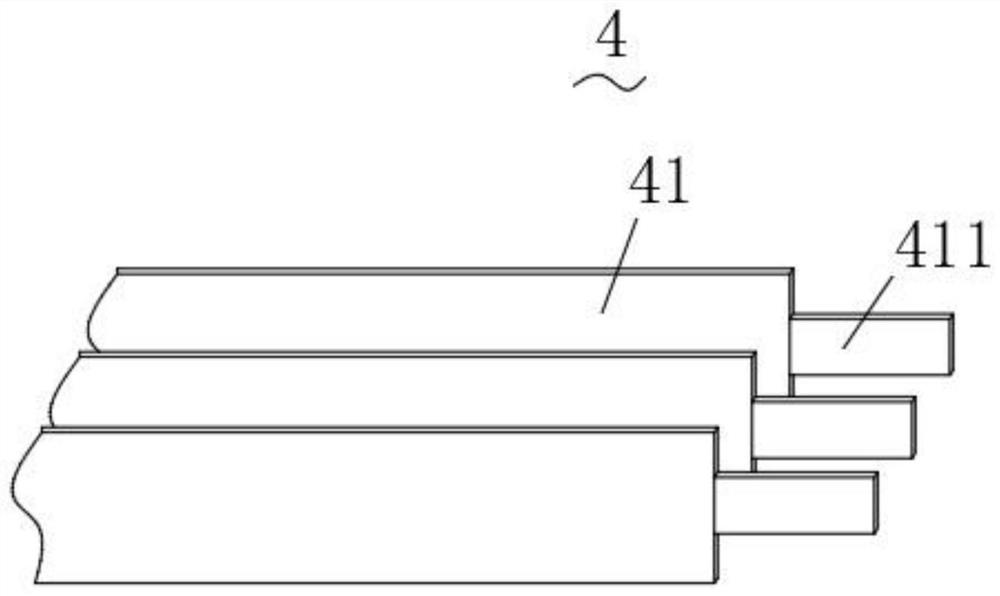

[0057] To make the negative pole piece:

[0058] Mix active material, conductive agent and dispersant, then add solvent to obtain negative electrode slurry, keep the solid content at 45-55%; then coat the negative electrode material on the surface of the negative electrode substrate, dry, roll, and cut Afterwards, the negative pole piece is obtained;

[0059] S2: Making batteries and packaging:

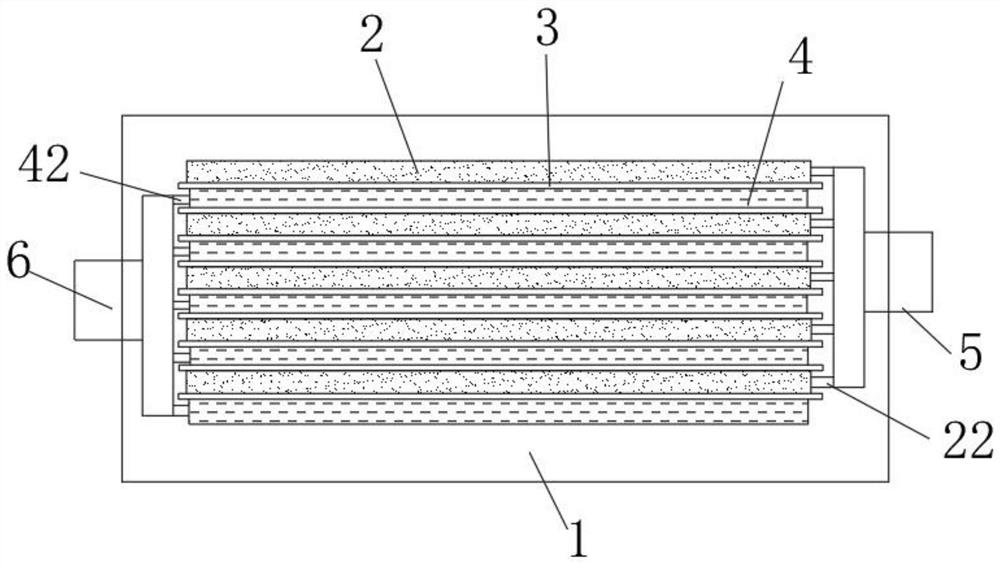

[0060] Laminate a plurality of positive elect...

Embodiment example 1

[0078] (1) Making the positive electrode sheet: mix lithium iron phosphate, graphene, carbon nanotubes and polyvinylidene fluoride according to a certain mass ratio, and use N-methylpyrrolidone as a solvent to make positive electrode slurry, and keep the solid content at 55-56%, and then apply it continuously and evenly on the carbon-coated aluminum foil, and obtain the positive pole piece after drying, rolling and cutting;

[0079] (2) Making the negative electrode sheet: mix graphite, graphene, carbon nanotubes and polyvinylidene fluoride according to a certain ratio, and keep the solid content at 50-51%; then apply it continuously and evenly on the carbon-coated copper foil , after drying, rolling, and slitting, the negative electrode sheet is obtained;

[0080] (3) Production of battery cells: Laminate the positive pole piece, diaphragm and negative pole piece to form a battery core, weld the tabs, and package them with aluminum-plastic film to obtain a battery;

[0081] ...

Embodiment example 2

[0087] (1) Making the positive electrode sheet: mix lithium iron phosphate, carbon nanofiber, Super P and polyvinylidene fluoride according to a certain mass ratio, and use N-methylpyrrolidone as the solvent to make the positive electrode slurry, and keep the solid content at 57-59%, and then apply it continuously and evenly on the carbon-coated aluminum foil, dry, roll, and cut to get the positive electrode sheet;

[0088] (2) Making the negative electrode sheet: keep the solid content of graphite, carbon nanofiber, Super P and polyvinylidene fluoride at 50-51%, and then apply it continuously and evenly on the carbon-coated copper foil, and dry and roll Negative pole pieces are obtained after pressing and cutting;

[0089] (3) Production of battery cells: Laminate the positive pole piece, diaphragm and negative pole piece to form a battery core, weld the tabs, and package them with aluminum-plastic film to obtain a battery;

[0090] (4) Battery baking: put the battery into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com