Instant nutritional meal replacement lotus root starch and preparation method thereof

A lotus root starch and instant technology, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food ingredients containing polysaccharides/gum, etc., can solve the problem of hot water brewing skills that are difficult for novices to master, affect the taste of food, and sugar intake Exceeding the standard and other problems, to achieve the effect of shortening the eating time and brewing time, improving the flavor and nutritional value, and reducing the intake of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

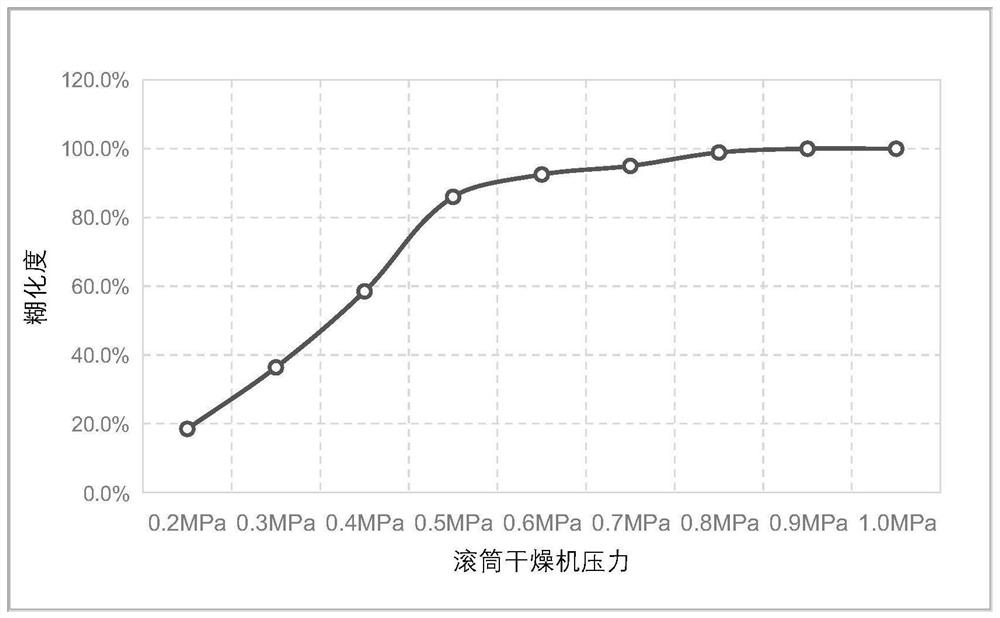

[0036] Take by weighing the lotus root starch that accounts for 20wt% of the total amount of lotus root starch and water, and the remainder gets water to adjust slurry to make lotus root starch slurry. 0.5MPa, 0.6MPa, 0.7MPa, 0.8MPa, 0.9MPa, 1.0MPa, rotating speed 3r / min, obtain lotus root starch block, after the prepared lotus root starch block is pulverized, pass 80 mesh sieves, make lotus root starch micropowder, lotus root starch micropowder Boiling granulation, the inlet air temperature is 100°C, the outlet air temperature is 50°C, after the granulation is formed, pass through a 60-mesh sieve, and then dry to obtain lotus root powder particles. The prepared lotus root powder is measured by a rapid viscosity analyzer to obtain figure 1 Effect of different drying pressure on gelatinization degree of instant lotus root powder.

[0037] according to figure 1 Obtain, along with the increase of pressure, the gelatinization degree of lotus root starch piece increases, and when ...

Embodiment 2

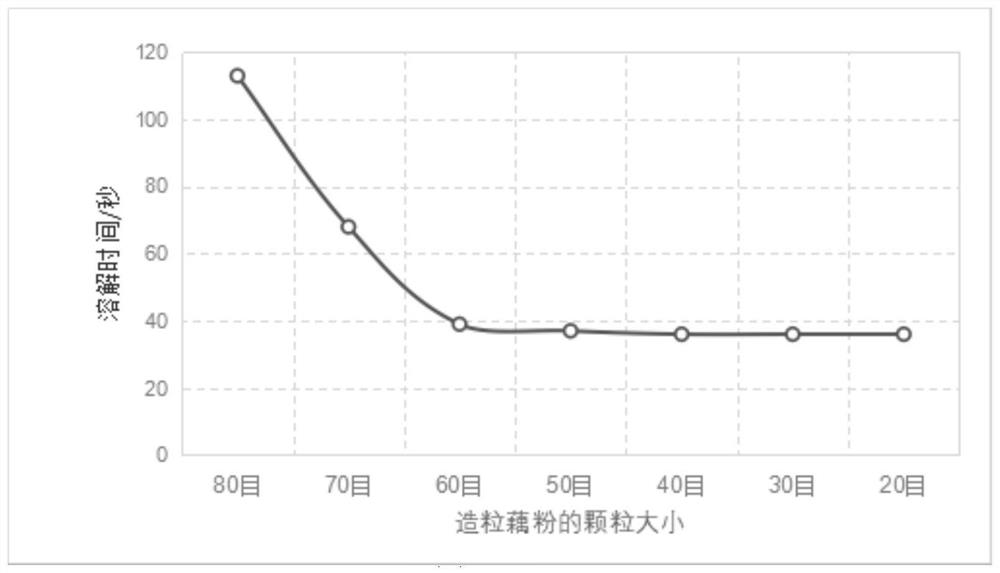

[0039] Take by weighing the lotus root starch that accounts for 20wt% of the total amount of lotus root starch and water, and the remainder is taken to adjust the slurry to make lotus root starch slurry, and the lotus root starch slurry is gelatinized and dried with a roller at a pressure of 0.6MPa and a rotating speed of 3r / min to obtain lotus root starch. Starch block, the obtained lotus root starch block is crushed and passed through an 80-mesh sieve to obtain a lotus root starch micropowder, which is boiled and granulated, with an inlet air temperature of 100°C and an outlet air temperature of 50°C. Mesh, 40 mesh, 50 mesh, 60 mesh, 70 mesh sieve, 80 mesh sieve, dry after sieving to obtain lotus root powder particles. The preparation ratio of the prepared lotus root powder is 1:6. Add 30g of lotus root powder to 180mL of water at room temperature (25°C) and quickly brew. Measure the dissolution rate of lotus root powder with different particle sizes under this brewing operat...

Embodiment 3

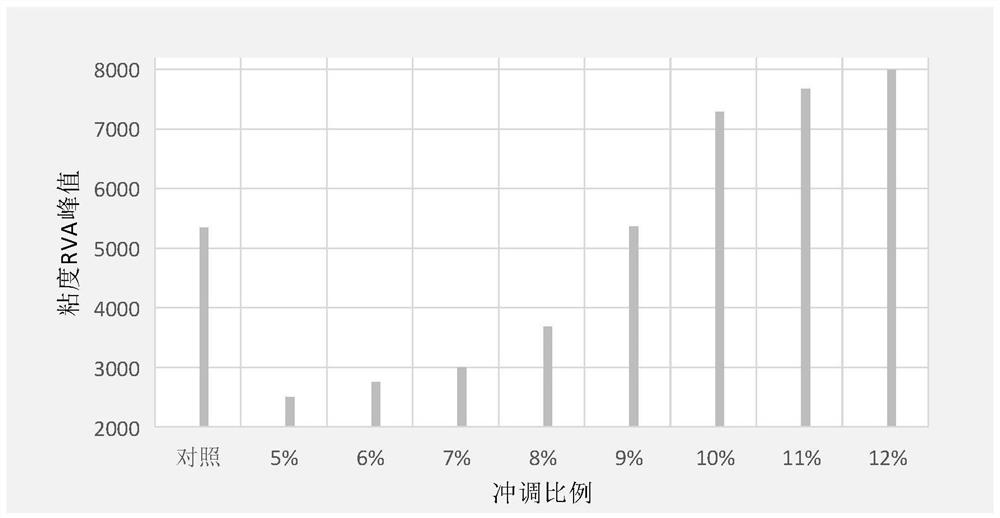

[0042] Take by weighing the lotus root starch that accounts for 20wt% of the total amount of lotus root starch and water, and the remainder is taken to adjust the slurry to make lotus root starch slurry, and the lotus root starch slurry is gelatinized and dried with a roller at a pressure of 0.6MPa and a rotating speed of 3r / min to obtain lotus root starch. Starch block, the obtained lotus root starch block is pulverized and passed through a 80-mesh sieve to obtain a lotus root starch micropowder, which is boiled and granulated, with an inlet air temperature of 100°C and an air outlet temperature of 50°C, and passes through a 60-mesh sieve after granulation. Sieve and dry to obtain lotus root powder particles. According to the prepared lotus root starch, use 25°C normal temperature water to prepare according to different preparation ratios.

[0043] Control group: commercially available instant lotus root powder, with a brewing ratio of 1:6, that is, add 180 mL of boiling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com