Preparation method of Blue-TiO2/CNT-PbO2 electrode material doped with carbon nanotubes

A carbon nanotube and electrode material technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem of unstable chemical composition and properties of the electrode surface, easy deactivation of the electrode, Short service life and other problems, to solve the effect of lead layer shedding, stable electrode structure and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

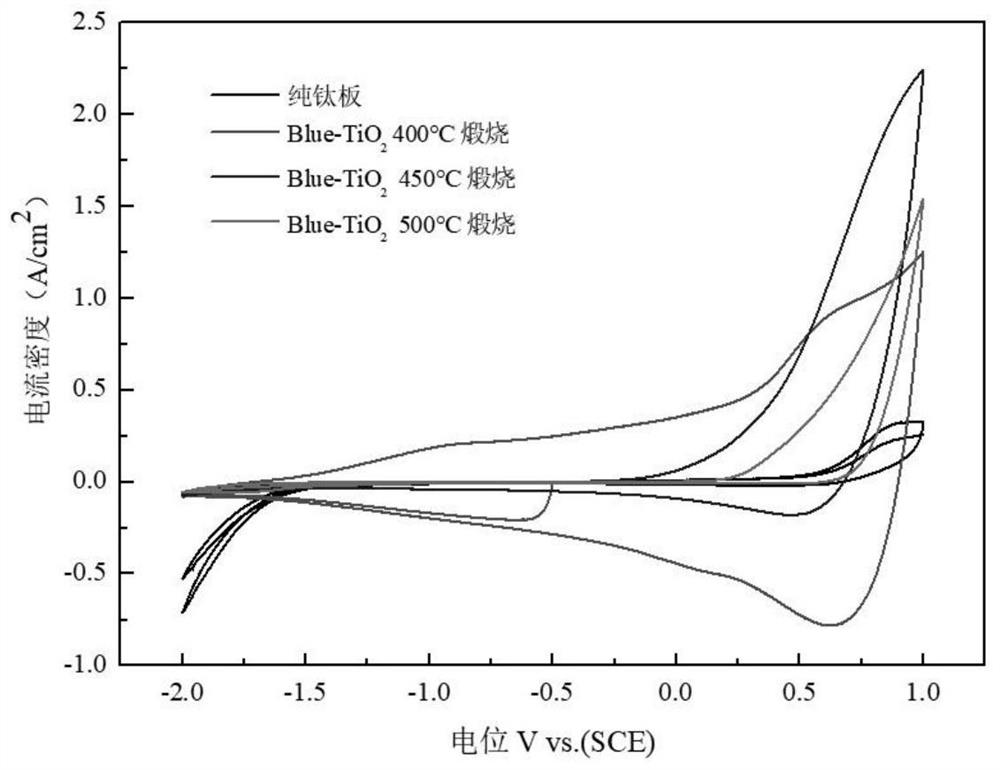

Embodiment 1

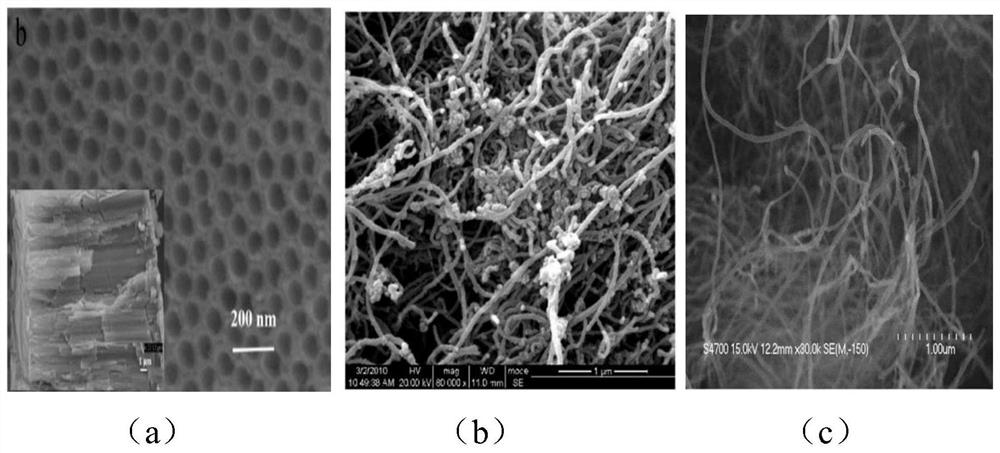

[0036] The titanium plate was selected as the electrode substrate, and the titanium plate substrate was anodized twice in the ethylene glycol electrolyte of ammonium fluoride and distilled water, and then electrochemically reduced in 10% formic acid solution for 5 minutes to prepare the blue electrode. Nanotubes, CNT-PbO on the basis of blue nanotubes 2 Co-deposition to prepare Blue-TiO 2 / CNT-PbO 2 Electrode material:

[0037] First, pretreat the titanium plate (40mm×40mm×1mm), quickly polish the titanium plate with sandpaper (320, 600, 1500 mesh), and then measure 25.2mL of concentrated sulfuric acid to 200mL to make 20% concentrated sulfuric acid , continue to digest in the solution for 30min, rinse with deionized water after cooling; etching: configure 20% oxalic acid solution, (weigh 20g of oxalic acid, and dilute to 100mL with distilled water) place the titanium plate vertically in oxalic acid at 98°C Etched in the solution for 2.0h, and cleaned with a large amount of...

Embodiment 2

[0041] Embodiment 2 (comparative example)

[0042] The difference from Example 1 is: in the preparation of Blue-TiO 2 The calcination temperature set at the time is 400°C, and the prepared material is marked as Blue-TiO 2 Calcined at 400°C.

Embodiment 3

[0043] Embodiment 3 (comparative example)

[0044] The difference from Example 1 is: in the preparation of Blue-TiO 2 The calcination temperature set at 500°C, the prepared material is marked as Blue-TiO 2 Calcined at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com