A high-strength shape-memory chitosan-based hydrogel and its preparation method and application

A chitosan and hydrogel technology, applied in the field of biomedical engineering materials, can solve the problems of lack of mechanical properties and shape memory properties, and achieve the effects of simple preparation and application process, improved mechanical properties, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

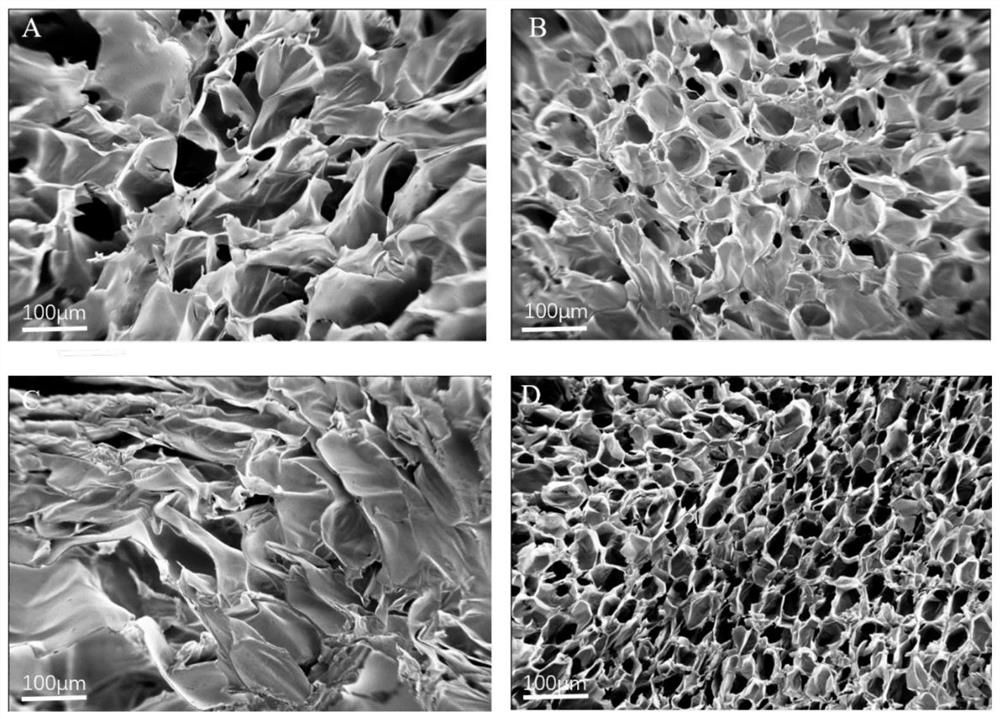

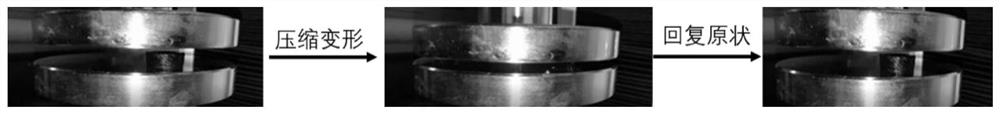

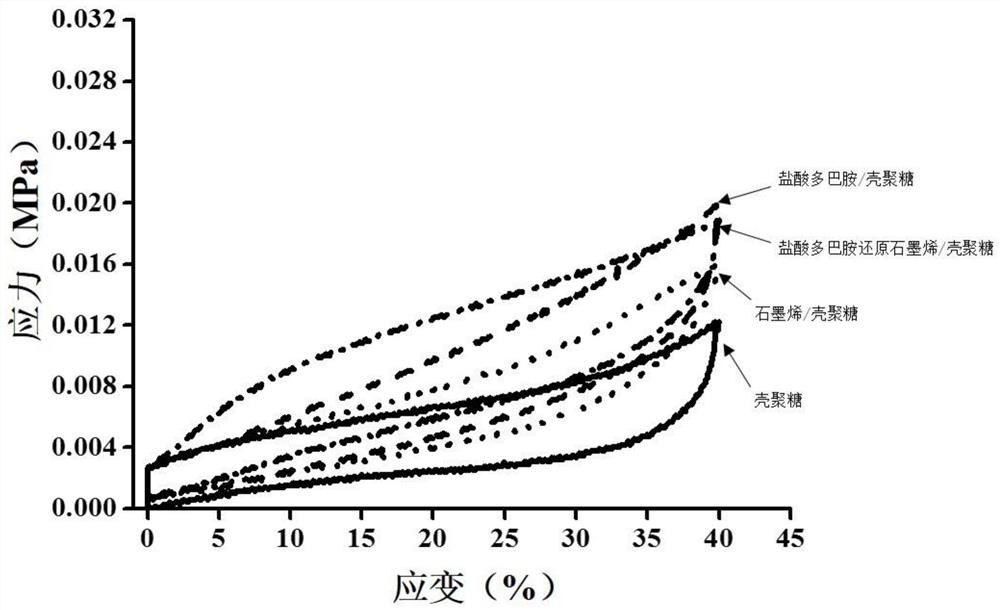

[0025] At room temperature, taking 0.21g of chitosan with a degree of deacetylation of 90% was dissolved in 10g of 3wt% acetic acid solution, stirred on a magnetic stirrer at 25°C for 6h, then added 0.09g of citric acid, and continued to stir for 4 Hour, obtain chitosan solution, then add 0.05g dopamine hydrochloride to chitosan solution and continue to stir on magnetic stirrer 6h, the chitosan-based solution that forms is poured in the mold (get rid of air bubbles) and put into-20 ℃ freezer Freeze for 12 hours. After being taken out from the freezer, it was thawed with 0.5M sodium hydroxide solution for 6 hours, washed with distilled water until the pH was neutral after thawing completely, and freeze-dried to obtain a high-strength shape memory chitosan-based hydrogel. The morphology of the high-strength shape-memory chitosan-based hydrogel is shown in Fig. figure 1 As shown in B, according to figure 1 B shows that the high-strength shape-memory chitosan-based hydrogel has ...

Embodiment 2

[0028] At room temperature, taking 0.21g of chitosan with a degree of deacetylation of 90% was dissolved in 10g of 3wt% acetic acid solution, stirred on a magnetic stirrer at 25°C for 6h, then added 0.09g of citric acid, and continued to stir for 4 Hour, obtain chitosan solution, then add 0.007g graphene oxide in chitosan solution, continue to stir 6h on magnetic stirrer with ultrasonic cleaner ultrasonic 15min. The resulting chitosan-based solution was poured into a mold (to exclude air bubbles) and placed in a -20°C freezer for 12 hours. After being taken out from the freezer, it was thawed with 0.5M sodium hydroxide solution for 6 hours, washed with distilled water until the pH was neutral after thawing completely, and freeze-dried to obtain a high-strength shape memory chitosan-based hydrogel. The morphology of the high-strength shape-memory chitosan-based hydrogel is shown in Fig. figure 1 C, according to figure 1 C shows that the high-strength shape-memory chitosan-bas...

Embodiment 3

[0031] At room temperature, taking 0.21g of chitosan with a degree of deacetylation of 90% was dissolved in 10g of 3wt% acetic acid solution, stirred on a magnetic stirrer at 25°C for 6h, then added 0.09g of citric acid, and continued to stir for 4 Hour, obtain chitosan solution, then add 0.05g dopamine hydrochloride and 0.007g graphene oxide in chitosan solution, continue to stir 6h on magnetic stirrer with ultrasonic cleaner ultrasonic 15min. The resulting chitosan-based solution was poured into a mold (to exclude air bubbles) and placed in a -20°C freezer for 12 hours. After being taken out from the freezer, it was thawed with 0.5M sodium hydroxide solution for 6 hours, washed with distilled water until the pH was neutral after thawing completely, and freeze-dried to obtain a high-strength shape memory chitosan-based hydrogel. The morphology of the high-strength shape-memory chitosan-based hydrogel is shown in Fig. figure 1 C, according to figure 1 C shows that this high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com