Preparation method of metal-doped TiO2 nanotube modified by expansion type self-assembly layer

A metal-doped, self-assembled layer technology, applied in nanotechnology, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of large specific surface area of nanomaterials, easy agglomeration, difficult nanomaterials, etc., to improve the affinity , Overcome the effect of poor dispersion and controllable matrix affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

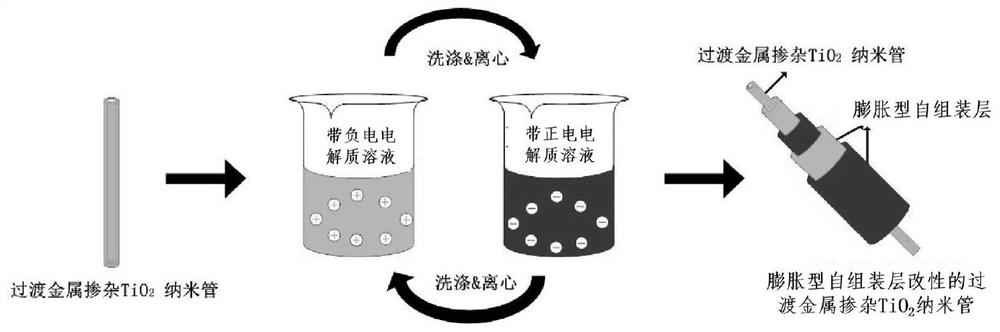

[0036] Embodiments of the present invention provide a metal-doped TiO modified by an expanded self-assembled layer 2 The preparation method of nanotube mainly comprises the following steps:

[0037] S1. Preparation of metal-doped TiO 2 nanotube

[0038] The present invention adopts hydrothermal synthesis method to prepare metal-doped TiO 2 Nanotubes, which mainly include the following steps:

[0039] Fe(NO 3 ) 3 9H 2 O or Ni(NO3 ) 2 ·6H 2 O and TiO 2 Add the powder into 10mol / L sodium hydroxide solution at a molar ratio of 1:10~15, stir evenly to obtain the first suspension, in which 10mol / L sodium hydroxide solution and TiO 2 The mass ratio of the powder is 20-30:1, the first suspension is transferred to a polytetrafluoroethylene reactor for hydrothermal reaction, and the reaction is carried out at a temperature of 130-160°C for 24-48 hours to obtain the reactant, which is to be reacted After the product is cooled to room temperature, the solid matter in the reactan...

Embodiment 1

[0077] Metal-doped TiO modified by an intumescent self-assembled layer 2 The preparation method of nanotube mainly comprises the following steps:

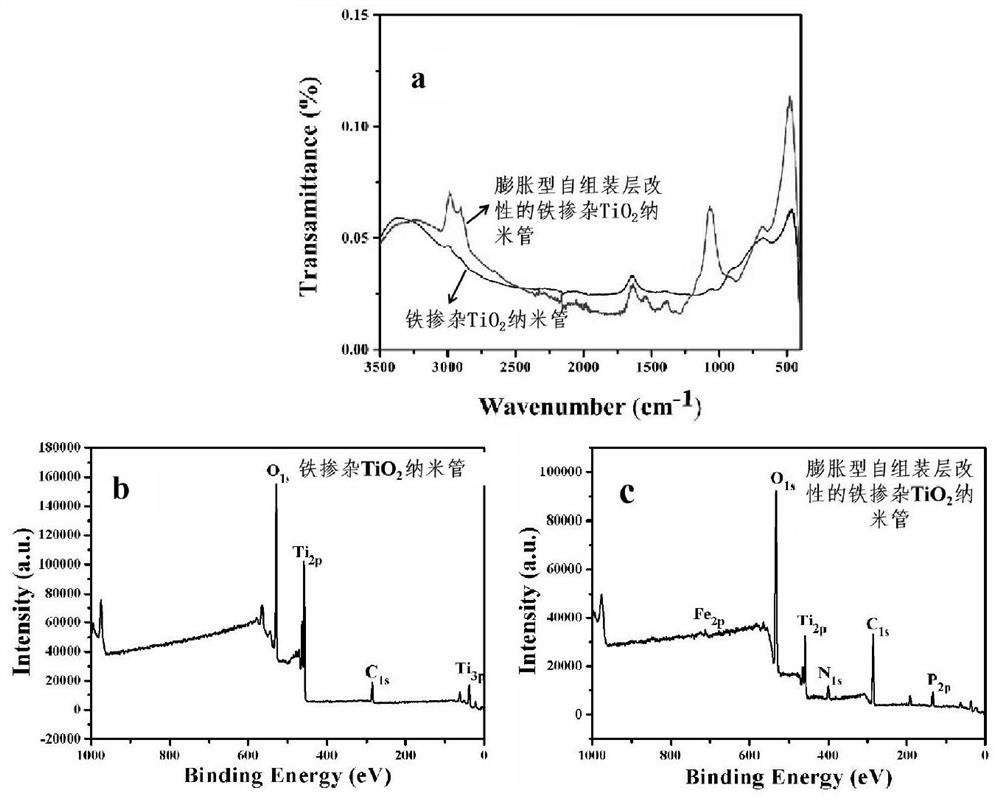

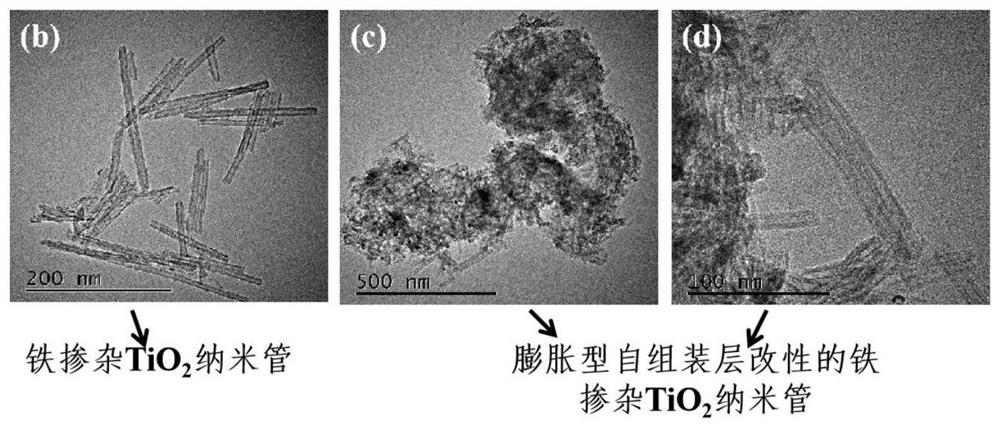

[0078] S1. Preparation of iron-doped TiO 2 nanotube

[0079] 0.8g Fe(NO 3 ) 3 9H 2O was added to 30mL of 10mol / L sodium hydroxide solution and stirred until completely dissolved, then 1.6g of TiO was added 2 powder, stir evenly to obtain the first suspension, transfer the first suspension obtained by stirring uniformly to a 50ml polytetrafluoroethylene reactor, and react at a temperature of 150°C for 36h to obtain the reactant, and the reactant is cooled to After room temperature, centrifuge to separate the solid matter in the reactant, then wash with 0.1mol / L hydrochloric acid and deionized water to neutrality, and dry the washed solid matter in an oven at 50°C for 12 hours to obtain iron doped TiO 2 nanotube;

[0080] S2, prepare positive electrolytic solution and negative electrolytic solution respectively

[0081] Weig...

Embodiment 2

[0095] Metal-doped TiO modified by an intumescent self-assembled layer 2 The preparation method of nanotube mainly comprises the following steps:

[0096] S1. Preparation of Ni-doped TiO 2 nanotube

[0097] 0.5g Ni(NO 3 ) 2 ·6H 2 Add O to 30mL of 10mol / L sodium hydroxide solution and stir until completely dissolved, then add 1.6g of TiO 2 Powder, stir evenly to obtain the first suspension, transfer the first suspension obtained by stirring evenly to a 50ml polytetrafluoroethylene reactor, react at a temperature of 130°C for 48h, obtain the reactant, and wait for the reactant to cool to room temperature Afterwards, centrifuge to separate the solid matter in the reactant, then wash it with 0.1mol / L hydrochloric acid and deionized water to neutrality, and dry the washed solid matter in an oven at 50°C for 12 hours to obtain iron doped TiO 2 nanotube;

[0098] S2, prepare positive electrolytic solution and negative electrolytic solution respectively

[0099] S21, preparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com