Preparation method of long-life copper-based composite material

A technology of copper-based composite materials and copper-based alloys, which is applied in the field of electrochemistry, can solve the problems of catalytic activity to be improved, and the service life of electrocatalytic electrodes has not been studied, so as to achieve the effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

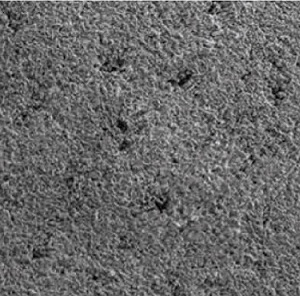

Embodiment 1

[0067] A method for preparing a long-life copper-based composite material, comprising the steps of:

[0068] (1) Pretreating the copper-based alloy; the copper-based alloy is copper-nickel-nickel alloy.

[0069] Among them, the pretreatment of step (1) is grinding and inorganic degreasing: the grinding is: use 200#, 600#, 1200# sandpaper for sanding in sequence.

[0070] Degreasing is 15g / L Na 2 CO 3 , 10g / L Na 3 PO 4 . 12H 2 O, 10 g / L Na 2 SiO 3 , the temperature is 50 o C, time 2min.

[0071] (2) The copper-containing solution is used as the electrolyte, and the copper-based alloy is used as the cathode, and the electrochemical deposition reduction is carried out at a very high negative bias voltage.

[0072] Wherein the copper-containing electrolyte in step (2) includes copper sulfate, sulfuric acid, chloride ions and surfactants, the anode is an inert electrode or pure copper, and the copper-containing electrolyte: 140g / L CuSO 4 . 5H 2 O; 30g / L H 2 SO 4 ; 40g / ...

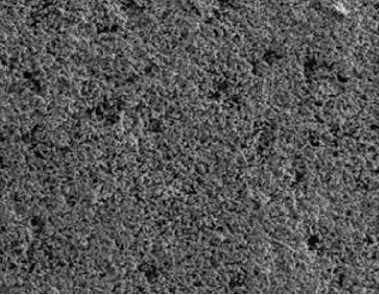

Embodiment 2

[0082] A method for preparing a long-life copper-based composite material, comprising the steps of:

[0083] (1) Pretreating the copper-based alloy; the copper-based alloy is copper-nickel-nickel alloy.

[0084] Among them, the pretreatment of step (1) is grinding and inorganic degreasing: the grinding is: use 200#, 600#, 1200# sandpaper for sanding in sequence.

[0085] Degreasing is 15g / L Na 2 CO 3 , 10g / L Na 3 PO 4 . 12H 2 O, 10 g / L Na 2 SiO 3 , the temperature is 50 o C, time 2min.

[0086] (2) The copper-containing solution is used as the electrolyte, and the copper-based alloy is used as the cathode, and the electrochemical deposition reduction is carried out at a very high negative bias voltage.

[0087] Wherein the copper-containing electrolyte in step (2) includes copper sulfate, sulfuric acid, chloride ions and surfactants, the anode is an inert electrode or pure copper, and the copper-containing electrolyte: 145g / L CuSO 4 . 5H 2 O; 32.5g / L H 2 SO 4 ; ...

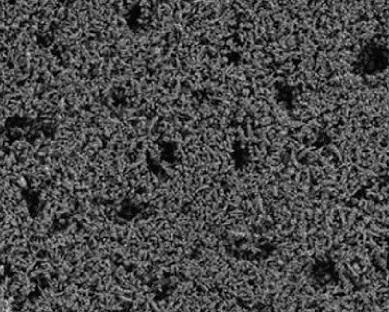

Embodiment 3

[0097] A method for preparing a long-life copper-based composite material, comprising the steps of:

[0098] (1) Pretreating the copper-based alloy; the copper-based alloy is copper-nickel-nickel alloy.

[0099] Among them, the pretreatment of step (1) is grinding and inorganic degreasing: the grinding is: use 200#, 600#, 1200# sandpaper for sanding in sequence.

[0100] Degreasing is 15g / L Na 2 CO 3 , 10g / L Na 3 PO 4 . 12H 2 O, 10 g / L Na 2 SiO 3 , the temperature is 50 o C, time 2min.

[0101] (2) The copper-containing solution is used as the electrolyte, and the copper-based alloy is used as the cathode, and the electrochemical deposition reduction is carried out at a very high negative bias voltage.

[0102] The copper-containing electrolyte in step (2) includes copper sulfate, sulfuric acid, chloride ions and surfactants, the anode is an inert electrode or pure copper, and the copper-containing electrolyte: 150g / L CuSO 4 . 5H 2 O; 35g / L H 2 SO 4 ; 45g / L Cl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com