Method for sintering polymer composite powder material at low temperature

A composite powder, low-temperature sintering technology, applied in the field of additive manufacturing, can solve the problems of high layer thickness that cannot be sintered, limited 3D molding speed, large laser energy loss, etc., to improve anisotropy, excellent electrical conductivity, and reuse. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

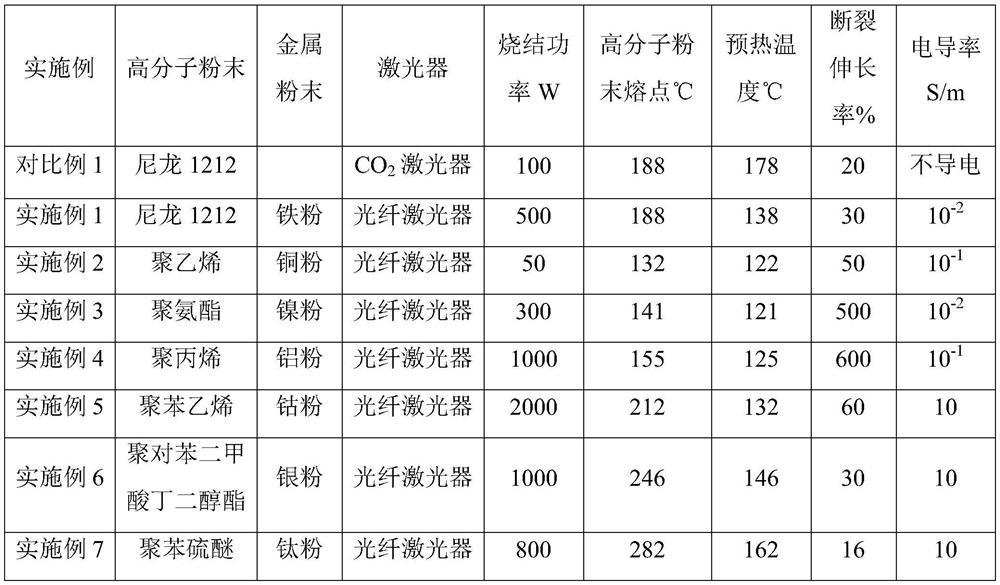

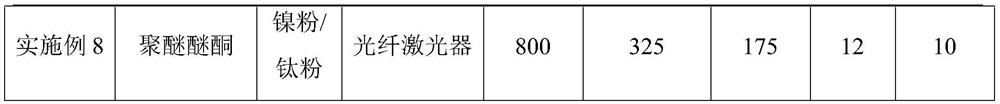

Examples

Embodiment 1

[0027] Step 1: Add 85 parts of nylon 1212 powder with an average particle size of 60 μm and 15 parts of iron powder with an average particle size of 25 μm into a mixing device, and perform physical mixing to obtain a composite powder of nylon 1212 and iron powder;

[0028] Step 2: Put the composite powder of nylon 1212 and iron powder prepared above into the selective laser sintering equipment using a fiber laser with a wavelength of 1080mm as the laser source. The maximum power of the fiber laser is 500W, and the layer thickness is 0.1mm , the composite powder of nylon 1212 and iron powder is heated to 50°C (138°C) below the melting point of nylon 1212 powder, and then the powder is melted with a sintering power of 500W laser, and the sintering line spacing is 0.3mm to prepare nylon 1212 and iron powder. Powder sintered workpiece.

Embodiment 2

[0030] Step 1: Add 95 parts of polyethylene powder with an average particle size of 80 μm and 5 parts of copper powder with an average particle size of 50 μm into a stirring device for physical mixing;

[0031] Step 2: Put the composite powder of polyethylene and copper powder prepared above into the selective laser sintering equipment that uses the optical fiber as the laser source with a wavelength of 2000nm. The maximum power range of the fiber laser is 200W, and the layer thickness is 0.2 mm, the composite powder of polyethylene and copper powder is heated to 10°C below the melting point of polystyrene powder, and then the powder is melted with a sintering power of 50W laser, and the sintering line spacing is 0.08mm to prepare a sintered workpiece.

Embodiment 3

[0033] Step 1: Add 90 parts of polyurethane powder with an average particle size of 75 μm and 10 parts of nickel powder with an average particle size of 45 μm into a stirring device for physical mixing;

[0034] Step 2: Put the composite powder of polyurethane and nickel powder prepared above into the selective laser sintering equipment that uses optical fiber with a wavelength of 1060nm as the laser source. The maximum power range of the fiber laser is 300W, and the layer thickness is 0.1mm , the composite powder of polyurethane and nickel powder is heated to 20°C below the melting point of polyurethane powder, and then the powder is melted with a sintering power of 300W laser, and the sintering line spacing is 0.08mm to prepare a sintered workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Light source wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com