5G ceramic inductor and preparation process thereof

A preparation process, ceramic technology, applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, transformer/inductor coils/windings/connections, etc., can solve the problem of ceramic body strength, shock resistance, ceramic body and metallization Unsatisfactory layer bonding strength, too dense ferrite inductors, and affecting 5G signals, etc., to achieve the effect of improving earthquake resistance, improving welding strength, and avoiding signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation process of 5 g of the ceramic inductor of the present embodiment includes the steps of the following:

[0039] (1) Production: 95 parts of the grounded alumina porcelain powder (calcined alumina), 1.5 parts of silica, 1 calcium oxide, 1 zirconia 1, zirconia 1 Partially mixed glass phase powder, mixed with a mixed powder, a total weight of the powder, 1% of the PVA binder, 1%, dispersant silicon oil, 1% of the antifoam hydrosilicon oil, 1% lubricant hydrogen , Spray granulation process granulation into a loose load ratio 1.1g / m 3 , A water content of <0.5% of spherical powder, 90% of the particles and 60 mesh-250 mesh.

[0040] (2) Dry pressure molding: Dish is molded with powder with a dry press, form a blank, and pressure is 4T.

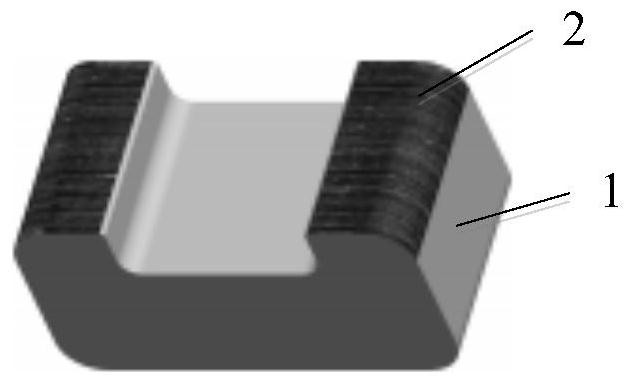

[0041] (3) Sintering: Mount the blank into the bench blanks, at a temperature of 1600 ° C, heat for 50 minutes, sintered the mold, to obtain figure 1 The 0402 model of the 0402 model, the density is 3.9g / cm 3 , Anti-fold inten...

Embodiment 2

[0047] The preparation process of 5 g of the ceramic inductor of the present embodiment includes the steps of the following:

[0048] (1) Production: 95 parts of the grounded alumina porcelain powder (calcined alumina), 2 parts of silica, 1 calcium oxide, 1 zirconia 1, zirconia 1 Partially mixed glass phase powder, mixed with a mixed powder, pressing a total weight of PVA binder 2%, 1% sodium carbonate, 0.5%, lubricant hydrogen acid, 1% , Spray granulation process granula formula is a loose color ratio 1.2g / m 3 , A water content of <0.5% of spherical powder, 90% of the particles and 60 mesh-250 mesh.

[0049] (2) Dry pressure molding: Dish is molded with powder with a dry press, form a blank, and pressure is 6T.

[0050] (3) Sintering: Mount the blank into the bench blanks, at a temperature of 1650 ° C, heat for 100 minutes, sintered the mold, to obtain figure 1 The 0402 type U-shaped ceramic body, density is 3.8g / cm 3 , Anti-fold intensity 286 MPa.

[0051] (4) Printing electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com