Integrated fungus growing equipment for loose tea fungus growing and fungus growing method for loose tea fungus growing

A fermentation equipment and loose tea technology, applied in biochemical equipment and methods, microorganism-based methods, specific-purpose bioreactors/fermentation tanks, etc., can solve problems such as food hazards, long fermentation cycle, and delicious Fuzhuan , to achieve the effect of improving taste, taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

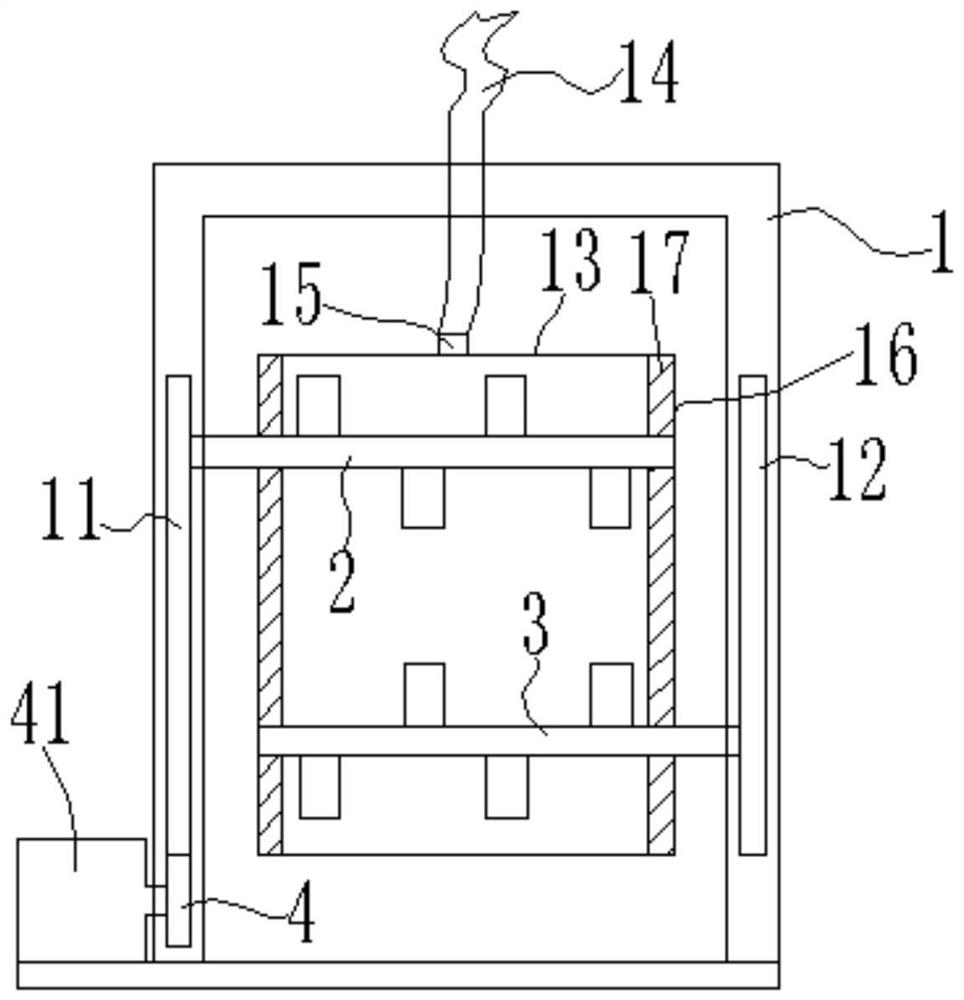

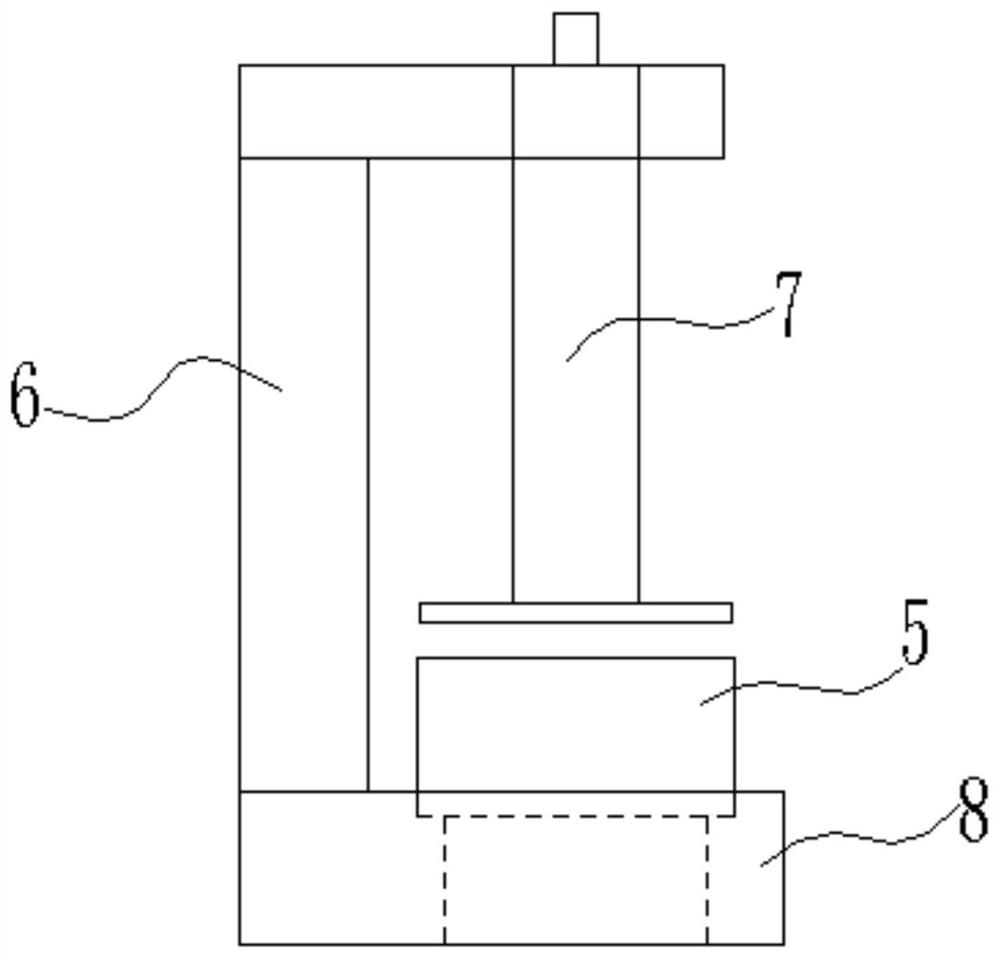

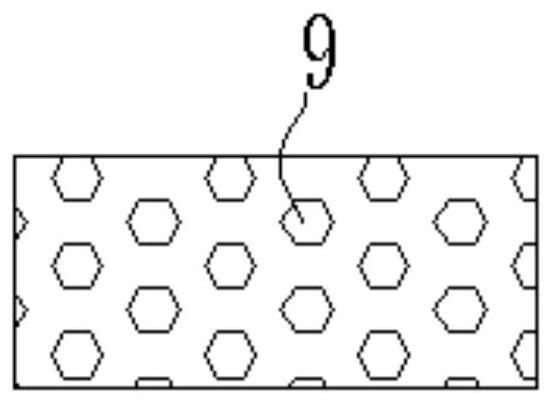

[0033] An integrated blooming equipment for blooming loose tea, including an incubator for cultivating strains, fermentation equipment for blooming loose tea, and a brick press for pressing tea bricks; the fermentation equipment includes: a support frame 1 , stirring rod one 2, stirring rod two 3, gear three 4, gear one 11 and gear two 12 are installed on both sides of the support frame 1, and the middle of gear one 11 and gear two 12 passes through stirring rod one 2 and stirring rod two 3 Fermentation tank 13 is connected in rotation, motor one 41 is provided under gear one 11 through gear three 4 meshing transmission; Steam pipe interface 15, electromagnetic coil 17 is arranged between insulating layer 16 and fermenter 13; Brick press comprises: mold 5, support bar 6, air pressure bar 7, mold table 8, mold 5 is placed on mold table 8, mold The bottom of 5 is provided with the small hole 9 that is used for water seepage, and the right side of mold table 8 is fixedly connecte...

Embodiment 2

[0041] Embodiment 2 differs from the embodiment in that:

[0042] The method for using the above-mentioned equipment to carry out loose tea blooming comprises the following steps:

[0043] S1: Production of test tube strains: put the culture medium in the incubator, the culture medium adopts Chavet's medium, and the incubator is sterilized under the high temperature environment of 121 ℃, and the sterilization time is 20min. coronoid under the conditions of inoculation, after inoculation at 28 ℃ ambient temperature, cultured for 71 hours, that is, the test tube strain;

[0044] S2: Second-level seed bottle expansion: 500mL triangular bottle filled with 50g of Maocha, add the same quality of water, seal the bottle with a cotton plug, sterilize at 121°C for 20min, after the temperature is lower than 40°C, connect one bottle to each bottle under aseptic conditions Cultivate the spores of the bacterial strains on the two-ring slant plane at 28°C for 75 hours to obtain the secondar...

Embodiment 3

[0049] The difference between embodiment 3 and embodiment 1 is:

[0050] The method for using the above-mentioned equipment to carry out loose tea blooming comprises the following steps:

[0051] S1: Production of test tube strains: put the medium in the incubator, medium PDA medium, and sterilize the incubator at a high temperature of 121°C for 20 minutes. The inclined plane of the medium is under the condition of aseptic operation Inoculate S. coronoidis under the environment, after inoculation, culture at 29°C for 72 hours to obtain the strain in test tube;

[0052] S2: Second-level seed bottle expansion: 500mL triangular bottle filled with 55g of Maocha, add the same quality of water, seal the bottle with a cotton plug, sterilize at 121°C for 20min, and after the temperature is lower than 40°C, connect one bottle to each bottle under aseptic conditions. To the spores of the two-ring slant strain, culture at 29°C for 76 hours to obtain the second-grade strain;

[0053] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com