Waste slag modifying additive

A technology of additives and slag, applied in the field of waste slag modified additives, can solve the problems of waste of mineral resources, accumulation of tailings resources, pollution of the environment, etc., and achieve the effects of strong resistance, accelerated crystallization, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

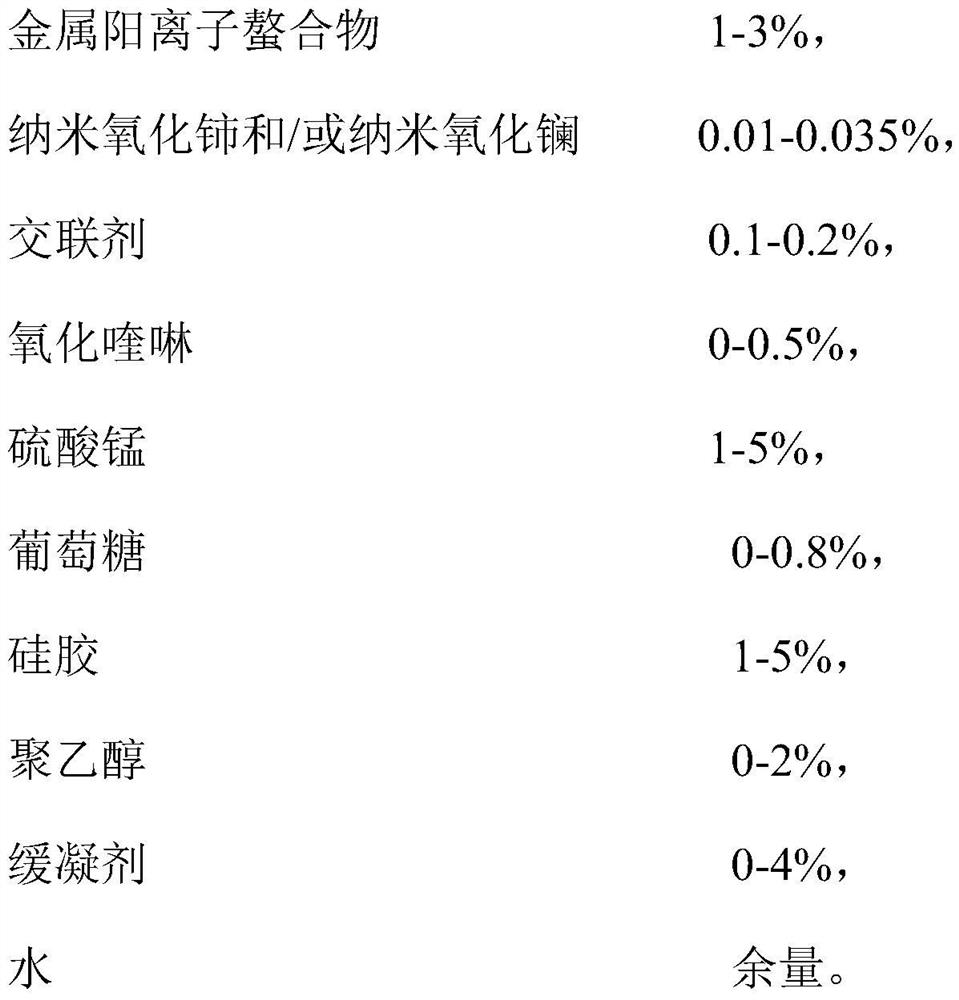

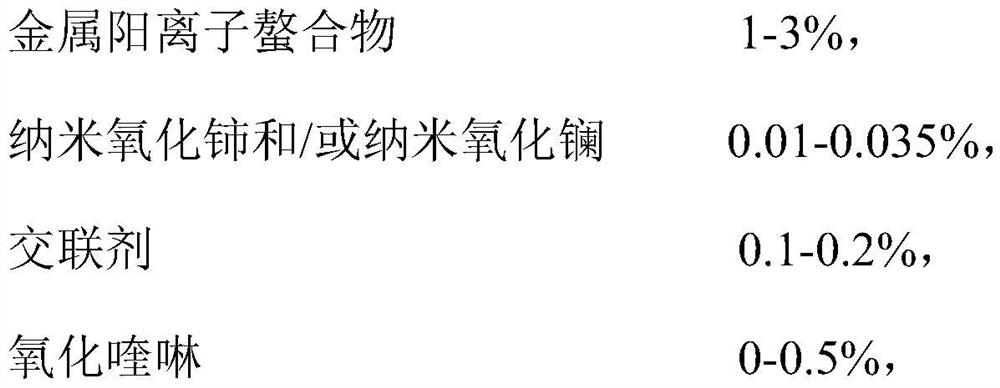

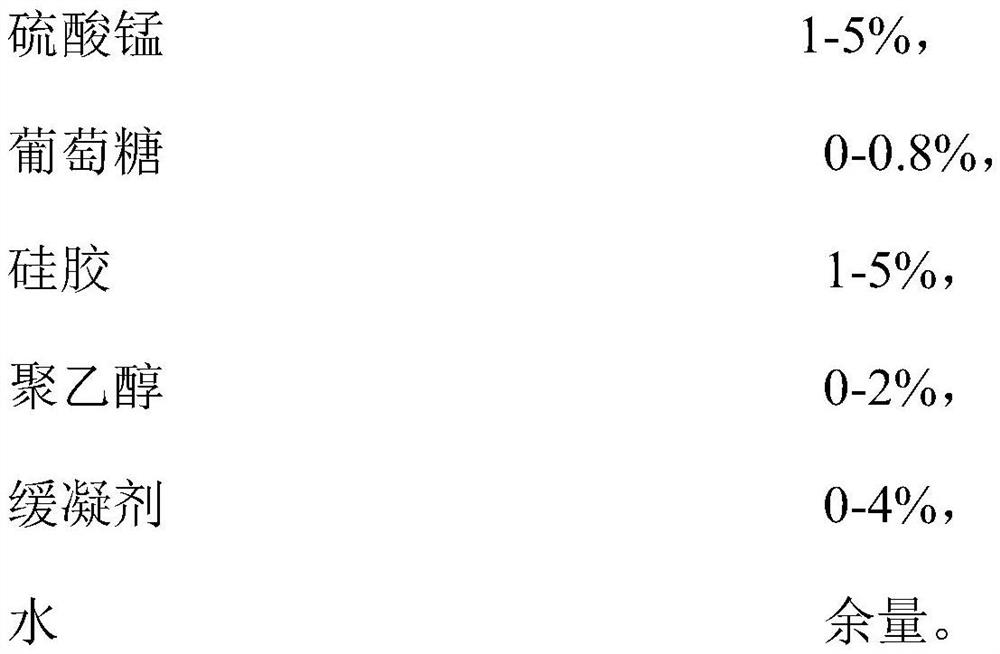

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for waste slag modified additive, comprising the following steps:

[0021] A. 87.07% of water is placed in the container, and 2% of metal cation chelate, 0.03% of nano cerium oxide, 0.3% of quinoline oxide are added successively and stirred at room temperature for 4 minutes;

[0022] B. After stirring evenly, then add 3% manganese sulfate, 1% polyethylene glycol, and 2% borax in turn, and continue stirring for 5-10 minutes;

[0023] C. Finally, add 0.1% ethylenediamine, 4% silica gel and 0.5% glucose, and stir for 8 minutes to prepare waste slag modification additive.

Embodiment 2

[0025] A preparation method for waste slag modified additive, comprising the following steps:

[0026] A. 90.53% of the water is placed in the container, followed by adding 1% metal cation chelate, 0.01% nano-cerium oxide, 0.01% nano-lanthanum oxide, 0.1% quinoline oxide and stirring at room temperature for 4 minutes;

[0027] B. After stirring evenly, then add 5% manganese sulfate, 0.1% polyethanol, and 1% sodium phosphate in sequence, and continue stirring for 5-10 minutes;

[0028] C. Finally, add 0.15% triethylenetetramine, 2% silica gel and 0.1% glucose, and stir for 8 minutes to prepare waste slag modification additive.

Embodiment 3

[0030] A preparation method for waste slag modified additive, comprising the following steps:

[0031] A. The water of 84.77% is placed in the container, add successively 3% metal cation chelate, 0.02% nano cerium oxide, 0.01% nano lanthanum oxide, 0.4% quinoline oxide and stir at normal temperature for 4 minutes;

[0032] B. After stirring evenly, then add 1% manganese sulfate, 0.8% polyethanol, and 4% sodium fluoride in sequence, and continue stirring for 5-10 minutes;

[0033] Finally, 0.2% paraformaldehyde, 5% silica gel and 0.8% glucose were added, stirred for 8 minutes, and waste slag modification additives were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com