Silver-iron oxide electric contact material with dispersed oxide particles and preparation method thereof

A technology of oxide particles and electrical contact materials, applied in the field of electrical contacts, can solve the problems of high content of low-melting impurity sodium, easy agglomeration, inability to effectively remove low-melting impurity sodium, etc., and achieves the effect of solving the problem of dispersion uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

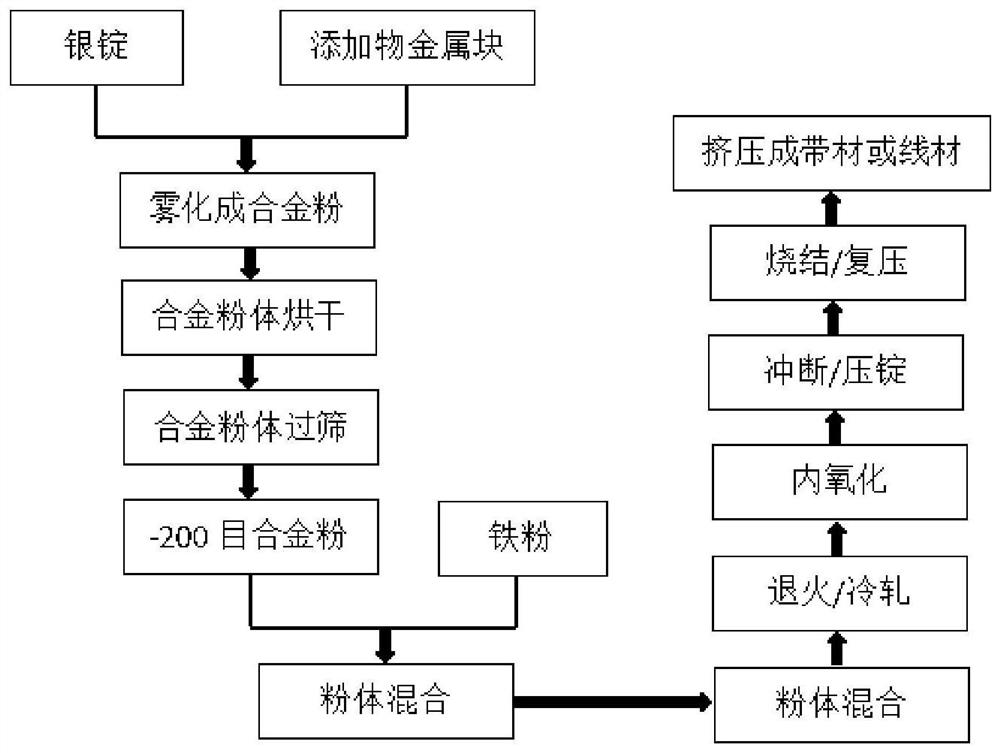

[0033] This implementation case proceeds as follows:

[0034] 1) Ag:Fe according to the weight percentage of the final product 2 o 3 :MoO 3 =93.6:5.4:1 requirements, take 25.318kg silver ingots and melt in a medium frequency induction heating furnace, then add 0.182 metal molybdenum blocks to form a silver-molybdenum alloy. Control the atomization temperature of the solution at 1280±20°C, and atomize the silver-molybdenum alloy into alloy powder under the atomization water pressure of 40±5MPa.

[0035] 2) Dry the silver-molybdenum atomized alloy powder at 250±10°C for 8h±10min to completely remove the moisture in the powder;

[0036] 3) Sieve the dried powder on a 200-mesh sieve, and the under-sieve is used as raw material powder for subsequent mixing with iron powder;

[0037] 4) Weigh 18.854 kg of -200 mesh silver-molybdenum alloy powder and 0.756 kg of carbonyl iron powder, and mix the powders in a plow-shovel mixer, and the mixing time is set at 4h±10min.

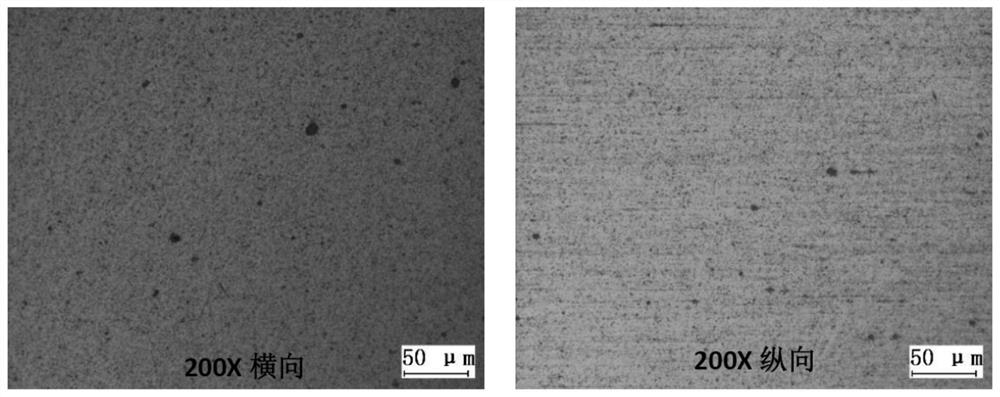

[0038]5) U...

Embodiment 2

[0043] This implementation case proceeds as follows:

[0044] 1) Ag:Fe according to the weight percentage of the final product 2 o 3 :Y 2 o 3 =93.6:5.4:1 requirement, take 25.286kg silver ingot and melt in medium frequency induction heating furnace, then add 0.214 metal yttrium block, form silver yttrium alloy. Control the atomization temperature of the solution at 1200±20°C, and atomize the silver-yttrium alloy into alloy powder under the atomization water pressure of 40±5MPa.

[0045] 2) Dry the silver yttrium atomized alloy powder at 250±10°C for 8h±10min to completely remove the moisture in the powder;

[0046] 3) Sieve the dried powder on a 200-mesh sieve, and the under-sieve is used as raw material powder for subsequent mixing with iron powder;

[0047] 4) Weigh 18.878 kg of -200 mesh silver-yttrium alloy powder and 0.756 kg of carbonyl iron powder, and mix the powders in a plow-shovel mixer, and the mixing time is set at 4h±10min.

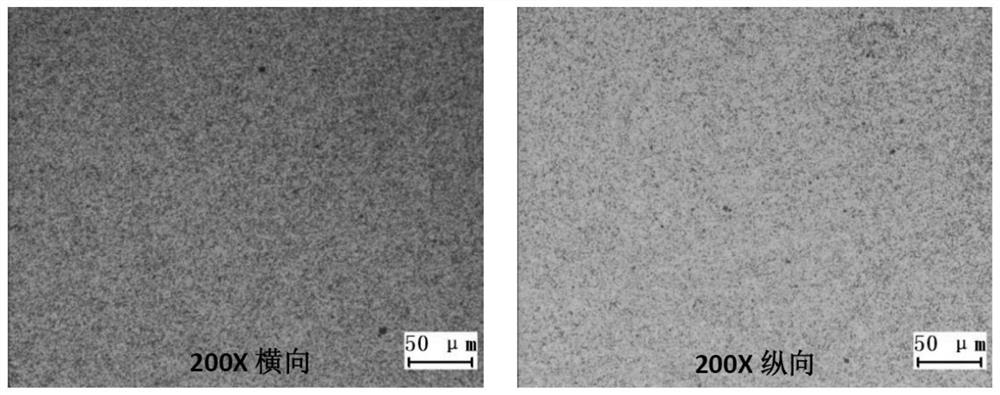

[0048] 5) Using a two-roller ho...

Embodiment 3

[0053] This implementation case proceeds as follows:

[0054] 1) Ag:Fe according to the weight percentage of the final product 2 o 3 :La 2 o 3 =93.6:5.4:1 requirement, take 25.27kg silver ingot and melt in medium frequency induction heating furnace, then add 0.23 metal lanthanum block to form silver lanthanum alloy. Control the atomization temperature of the solution at 1250±20°C, and atomize the silver-lanthanum alloy into alloy powder under the atomization water pressure of 40±5MPa.

[0055] 2) Dry the silver-lanthanum atomized alloy powder at 250±10°C for 8h±10min to completely remove the moisture in the powder;

[0056] 3) Sieve the dried powder on a 200-mesh sieve, and the under-sieve is used as raw material powder for subsequent mixing with iron powder;

[0057] 4) Weigh 18.89 kg of -200 mesh silver-lanthanum alloy powder and 0.756 kg of carbonyl iron powder, and mix the powders in a plow-shovel mixer, and the mixing time is set at 4h±10min.

[0058] 5) Using a two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com