Composite heavy metal contaminated soil remediation agent and preparation method thereof

A technology for polluted soil and remediation agents, applied in soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve the problems of poor effect of ordinary Portland cement, large amount of chemicals added, and high remediation costs, so as to reduce the leaching of heavy metals. Concentration and environmental risks, improved gelation reaction strength, and high resource utilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the composite heavy metal contaminated soil remediation agent, the specific process is as follows:

[0023] First, after washing the white mud with water, dry it at 40°C, ball mill it and pass it through a 100-mesh sieve; dry the metakaolin at 40°C, pass it through a ball mill and pass it through a 100-mesh sieve; Blast furnace slag was dried at 40°C, ball milled and passed through a 100-mesh sieve; the phosphogypsum was washed with water, dried at 40°C, ball-milled and passed through a 100-mesh sieve.

[0024] Among them, the heavy metal content in the metakaolin, blast furnace slag, and washed white mud and phosphogypsum is lower than the screening of the second type of construction land in the "Soil Environmental Quality Construction Land Soil Pollution Risk Control Standard" (GB36600-2018) Values, namely copper ≤ 18000mg / kg, hexavalent chromium ≤ 5.7mg / kg, cadmium ≤ 65mg / kg, arsenic ≤ 60mg / kg, lead ≤ 800mg / kg, mercury ≤ 38mg / kg, nickel ≤ 90...

Embodiment 1

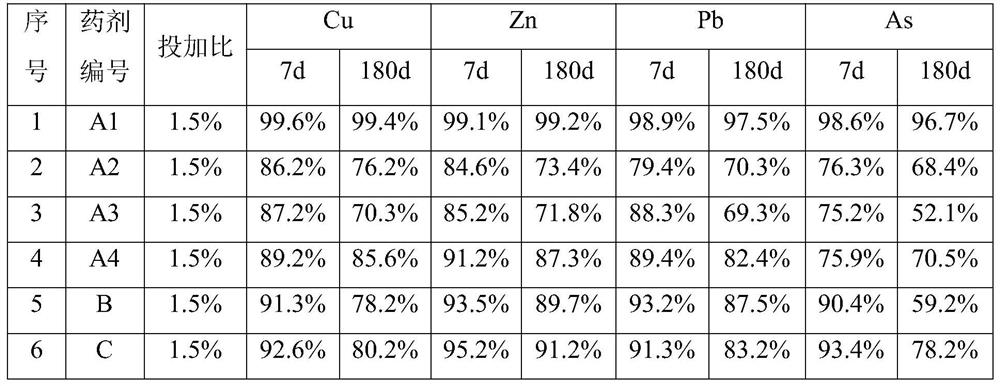

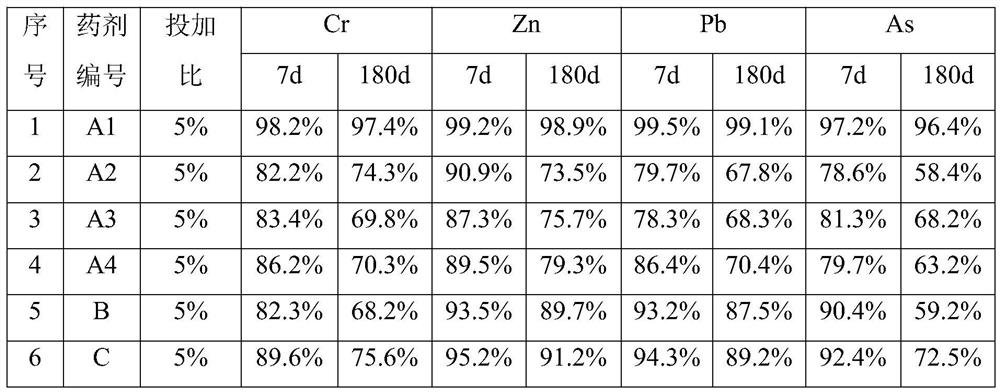

[0028] For the complex heavy metal polluted soil of a certain project, the toxic leaching is carried out according to the method of "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007). The contents of each heavy metal in the leachate are Cu: 5.63mg / L, Pb : 1.15mg / L, Zn: 4.98mg / L, As: 0.98mg / L; use the following restoration agents A1, A2, A3, A4 and agents B, C to solidify and stabilize the composite heavy metal contaminated soil.

[0029] Select white mud with a CaO content of 32%, wash the white mud with tap water, and then dry it at 40°C, use a ball mill to grind the white mud, and pass through a 100-mesh sieve; blast furnace slag with a CaO content of 28% Dry at ℃, ball mill and pass through a 100-mesh sieve; wash the phosphogypsum with tap water, then dry at 40°C, ball-mill the phosphogypsum with a ball mill, and pass through a 100-mesh sieve; metakaolin at 40°C Dried under the hood, ball milled and passed through a 100-mesh sieve....

Embodiment 2

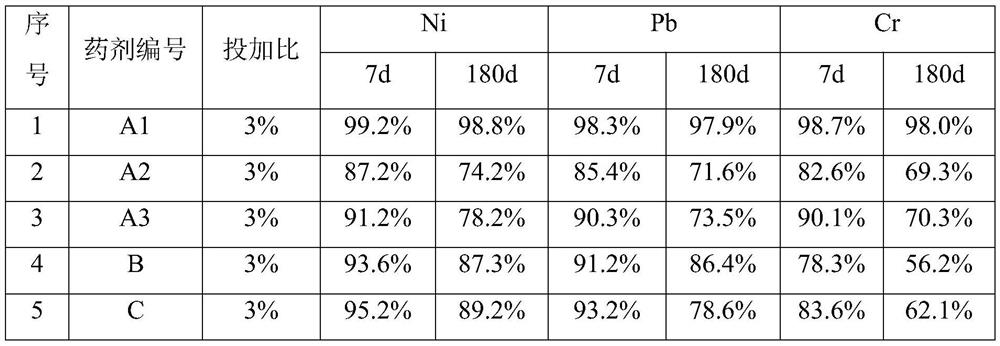

[0034] For the complex heavy metal polluted soil of a certain project, the toxic leaching is carried out according to the method of "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007). The contents of each heavy metal in the leachate are Ni: 26.9mg / L, Pb : 14.5mg / L, Cr: 3.53mg / L. The following remediation agents A1, A2, A3 and agents B, C were used to solidify and stabilize the complex heavy metal contaminated soil.

[0035]Select white mud with a CaO content of 35%, wash the white mud with tap water, and then dry it at 40°C, use a ball mill to grind the white mud, and pass through a 100-mesh sieve; blast furnace slag with a CaO content of 32% Dry at ℃, ball mill and pass through a 100-mesh sieve; wash the phosphogypsum with tap water, then dry at 40°C, ball-mill the phosphogypsum with a ball mill, and pass through a 100-mesh sieve; metakaolin at 40°C Dried under the hood, ball milled and passed through a 100-mesh sieve. Weigh 70kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com