Flexible composite lithium metal electrode, preparation thereof and lithium metal battery

A metal electrode, composite lithium technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of limited application, unstable electrochemical performance, and unsatisfactory lithium dendrite growth effect, etc. achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Correspondingly, the embodiment of the present invention also provides a preparation method of the flexible composite lithium metal electrode 01 above. The preparation method of the flexible composite lithium metal electrode 01 comprises the following steps:

[0062] S01: Provide a prestructure for flexible composite lithium metal electrodes;

[0063] S02: Pressing the pre-structure to form a flexible composite lithium metal electrode;

[0064] Wherein, the pre-structure in step S01 includes any structure in the following (1) to (4):

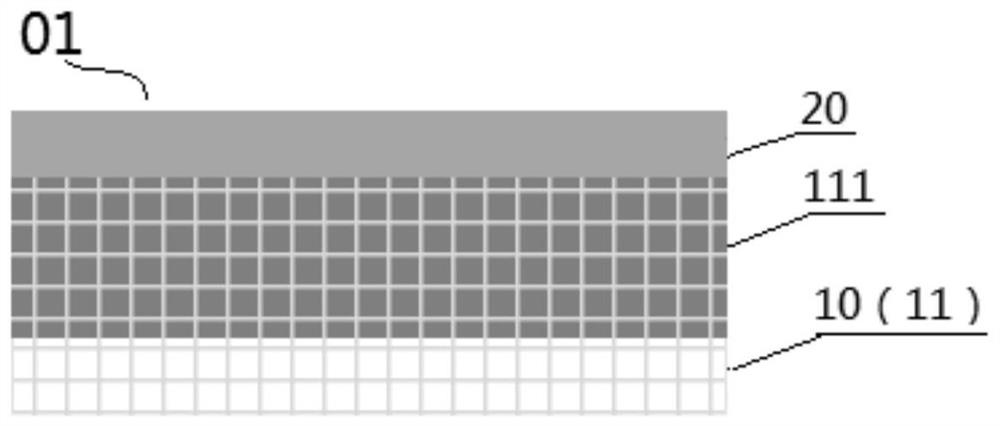

[0065] (1): comprising a non-lithophilic first conductive fiber layer and a lithium-based film layer attached to a surface of the first conductive fiber layer, that is, as figure 1 The prestructure of the flexible composite lithium metal electrode 01 shown;

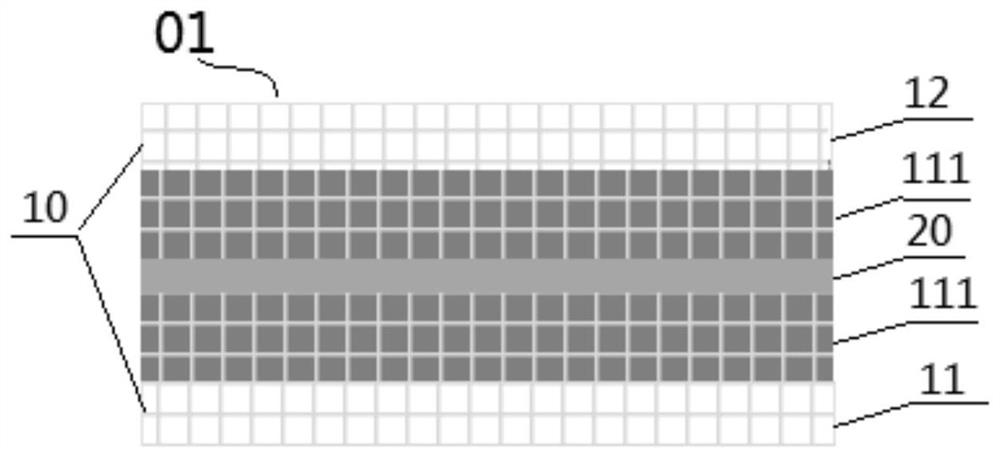

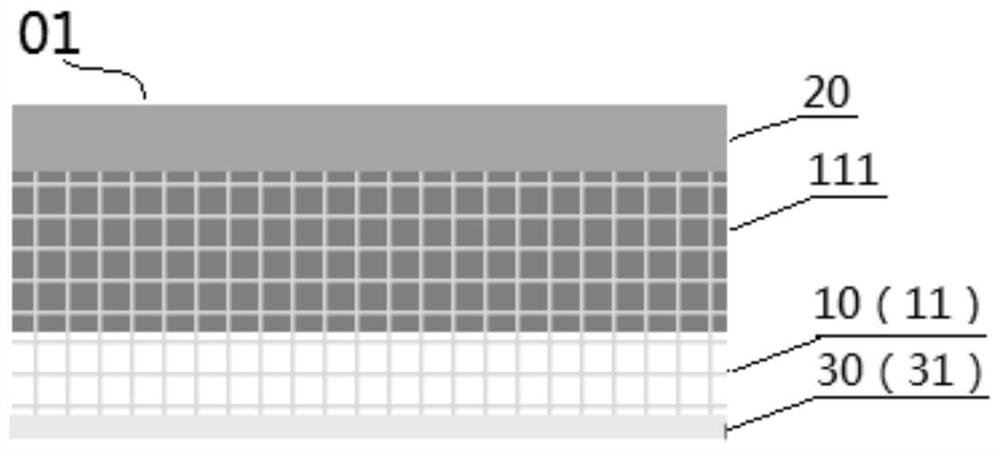

[0066] (2): including a non-lithophilic first porous polymer film layer, a non-lithophilic first conductive fiber layer and a lithium-based film layer, along the direction from th...

Embodiment 11

[0087] This embodiment provides a flexible composite lithium metal electrode and a preparation method thereof. The structure of the flexible composite lithium metal electrode is a sandwich structure of polyvinylidene fluoride-hexafluoropropylene copolymer porous membrane / copper-coated carbon felt / lithium-magnesium alloy layer; wherein, the polyvinylidene fluoride-hexafluoropropylene copolymer porous membrane contains mass Lithium nitrate and polyvinylidene fluoride-hexafluoropropylene copolymer at a ratio of 1:1; the lithium content of the lithium-magnesium alloy layer is 90wt%, and " / " means lamination and combination.

[0088] The preparation method of flexible composite lithium metal electrode includes as follows:

[0089] S1: Take an acetone solution containing 5wt% lithium nitrate and 5wt% polyvinylidene fluoride-hexafluoropropylene copolymer, scrape-coat it on a flat aluminum-plastic film, control the scrape-coating distance to 200 μm, put it in the fume hood after scrap...

Embodiment 12

[0093] This embodiment provides a flexible composite lithium metal electrode and a preparation method thereof. The structure of the flexible composite lithium metal electrode is a sandwich structure of polyvinylidene fluoride-hexafluoropropylene copolymer porous membrane / nickel-plated carbon felt / lithium-magnesium alloy layer; wherein, the polyvinylidene fluoride-hexafluoropropylene copolymer porous membrane contains mass Lithium nitrate and polyvinylidene fluoride-hexafluoropropylene copolymer at a ratio of 8:5; the lithium content of the lithium-magnesium alloy layer is 75wt%, and " / " means lamination and combination.

[0094] The preparation method of flexible composite lithium metal electrode includes as follows:

[0095] S1: Take an acetone solution containing 8wt% lithium nitrate and 5wt% polyvinylidene fluoride-hexafluoropropylene copolymer, scrape-coat it on a flat aluminum-plastic film, control the scrape-coating distance to 200 μm, put it in the fume hood after scrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com