Wound hemostasis and repair product based on hyaluronic acid and preparation method of product

A technology of hyaluronic acid and products, which is applied in the field of wound hemostatic repair products and its preparation, can solve the problems of easy shedding and displacement, low bonding fastness, etc., and achieve the effect of not easy displacement, increased strength, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

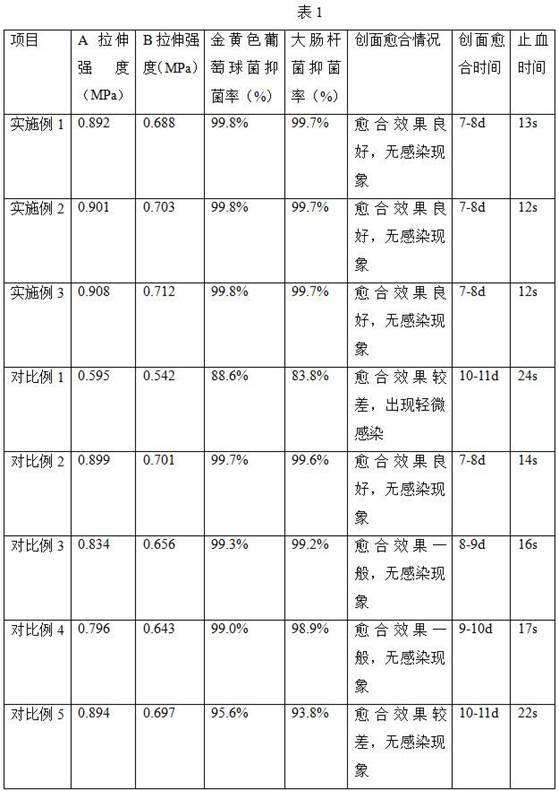

Examples

Embodiment 1

[0043] Step 1: Prepare materials;

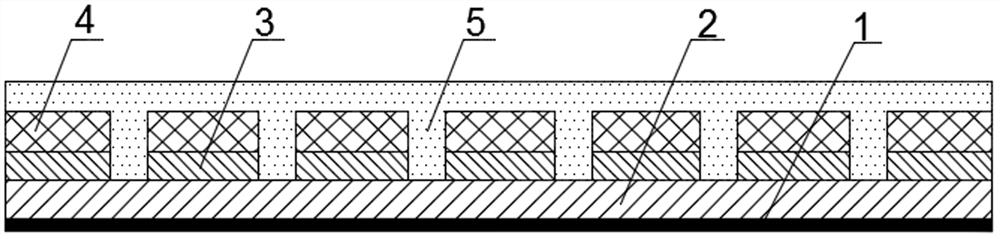

[0044] Step 2: Take the substrate, soak it in ethanol for 20 minutes, ultrasonically clean it, then wash it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the process, react in a constant temperature water bath at 25°C for 24 hours, wash with deionized water, and dry to obtain a pretreated substrate with a polydopamine layer on the upper surface; wherein the thickness of the polydopamine layer is 40nm, and the substrate is non-woven fabric;

[0045] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and carry out magnetron sputtering coating under the protection of argon gas, first coat a layer of titanium on the surface of the polydopamine layer of the pretreated substrate, and then A layer of silver is coated on the surface of the titanium layer to obtain a modified substrate (...

Embodiment 2

[0051] Step 1: Prepare materials;

[0052] Step 2: Take the substrate, soak it in ethanol for 25 minutes, ultrasonically clean it, then wash it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the process, react in a constant temperature water bath at 27°C for 26 hours, wash with deionized water, and dry to obtain a pretreated substrate with a polydopamine layer on the upper surface; wherein the substrate is a non-woven fabric, and the thickness of the polydopamine layer is 43nm;

[0053] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and carry out magnetron sputtering coating under the protection of argon gas, first coat a layer of titanium on the surface of the polydopamine layer of the pretreated substrate, and then A silver layer is coated on the surface of the titanium layer to obtain a modified substrate; t...

Embodiment 3

[0059] Step 1: Prepare materials;

[0060] Step 2: Take the substrate, soak it in ethanol for 30 minutes, ultrasonically clean it, then wash it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the process, react in a constant temperature water bath at 28°C for 28 hours, wash with deionized water, and dry to obtain a pretreated substrate with a polydopamine layer on the upper surface; wherein the substrate is a non-woven fabric, and the thickness of the polydopamine layer is 45nm;

[0061] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and carry out magnetron sputtering coating under the protection of argon gas, first coat a layer of titanium on the surface of the polydopamine layer of the pretreated substrate, and then A silver layer is coated on the surface of the titanium layer to obtain a modified substrate; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com