Zirconium-based catalyst for propylene epoxidation reaction and preparation method thereof

An epoxidation reaction and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of complex catalyst preparation methods and no obvious improvement in PO selectivity, etc. problem, to achieve the effect of broad market application prospects, environmental friendliness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

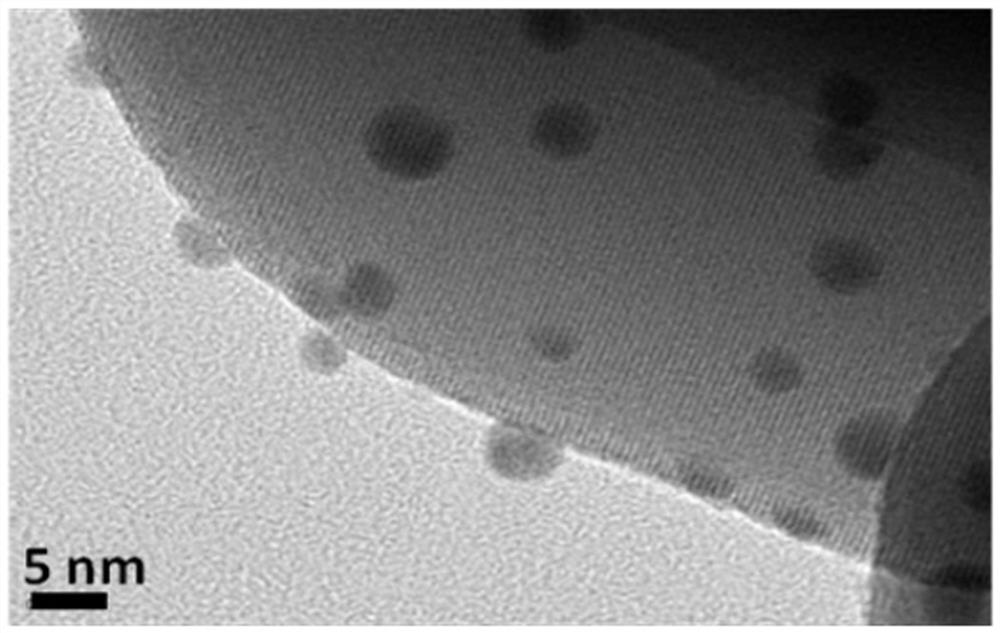

[0037] Embodiment 1: DP method prepares 1.0%Au / Zr-MFI-35 catalyst, and its preparation steps are as follows:

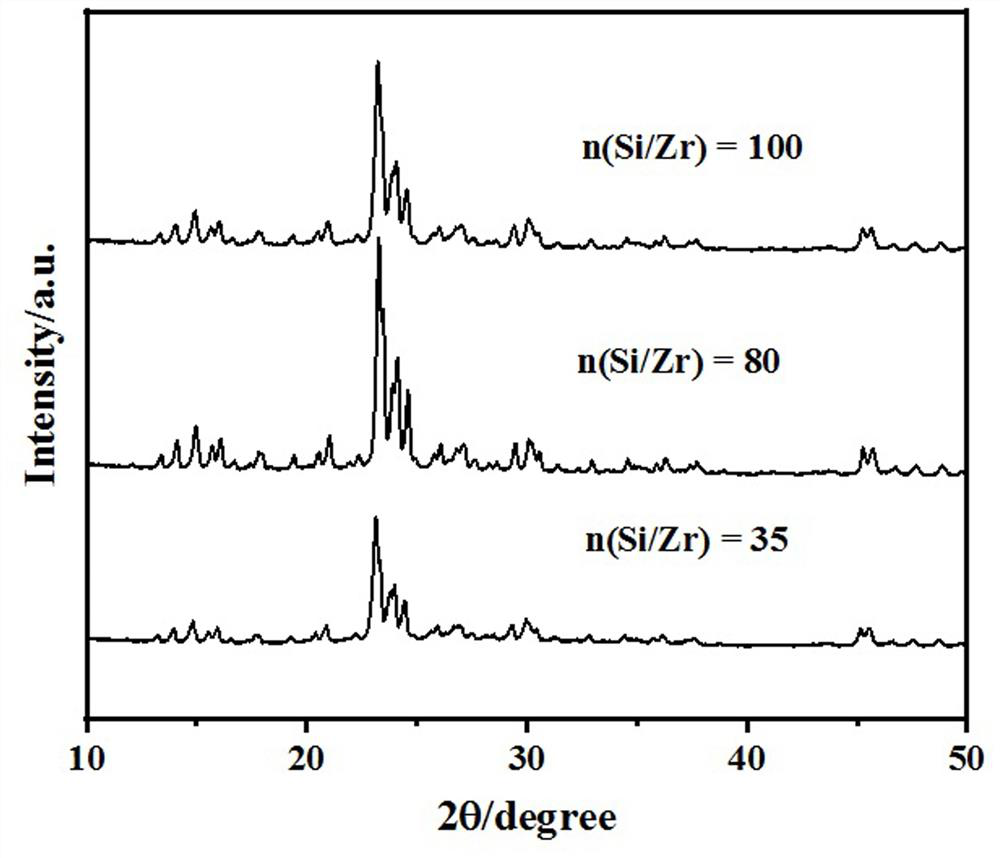

[0038] Weigh 2 g of Tween 20 (Tween 20, CP) and dissolve it in deionized water, add an appropriate amount of tetrapropylammonium hydroxide (TPAOH, 25%wt%) under stirring conditions, and measure 38.6 mL of ethyl orthosilicate (TEOS, AR) was slowly added to the above solution, stirred vigorously for 1 h, 2.3 g tetrabutyl zirconate was dissolved in 20 mL isopropanol (IPA), added dropwise to the above solution, and stirred vigorously for 1 h. 170 o C crystallized under normal pressure for 18 h, cooled to room temperature, washed several times with deionized water and ethanol, and 60 o C vacuum drying, 550 o C is calcined, and the obtained molecular sieve is recorded as Zr-MFI-35 carrier.

[0039] Take 0.02 gHAuCl 4 . 4H 2 O was added to 5 mL of distilled water, and 1 g of the above-prepared Zr-MFI-35 carrier was added. After stirring for 30 min, the 2 CO 3 Adjust ...

Embodiment 2

[0044] Embodiment 2: IMP method prepares 0.5%Au / Zr-MFI-35 catalyst, and its preparation steps are as follows:

[0045] Weigh 2 g of Tween 20 (Tween 20, CP) and dissolve it in deionized water, add an appropriate amount of tetrapropylammonium hydroxide (TPAOH, 25%wt%) under stirring conditions, and measure 38.6 mL of ethyl orthosilicate (TEOS, AR) was slowly added to the above solution, stirred vigorously for 1 h, 2.3 g tetrabutyl zirconate was dissolved in 20 mL isopropanol (IPA), added dropwise to the above solution, and stirred vigorously for 1 h. 170 o C crystallized under normal pressure for 18 h, cooled to room temperature, washed several times with deionized water and ethanol, and 60 o C vacuum drying, 550 o C is calcined, and the obtained molecular sieve is recorded as Zr-MFI-35 carrier.

[0046] Calculate the amount of gold solution, KOH solution and distilled water required for a theoretical gold loading of 1.0%. Measure a certain amount of HAuCl 4 ·3H 2 O soluti...

Embodiment 3

[0050] Embodiment 3: IMP method prepares 1.0%Au / Zr-MFI-60 catalyst, and its preparation steps are as follows:

[0051] Weigh 1.5 g of Tween 20 (Tween 20, CP) and dissolve it in deionized water, add 42.5 g of tetrapropylammonium hydroxide (TPAOH, 25%wt%) into the flask, and measure 38.6 mL of ethyl orthosilicate ( TEOS, AR) was slowly added to the above solution, stirred vigorously for 1 h, slowly and uniformly added 0.8869 g of zirconium ethylate dropwise to the above solution, and stirred vigorously for 1 h. 170 o C crystallized under normal pressure for 18 h, cooled to room temperature, washed several times with deionized water and ethanol, and 60 o C vacuum drying, 550 o C was calcined for 3 h to obtain a Zr-MFI-60 support with n(Si / Zr)=60.

[0052] Take 0.02 gHAuCl 4 . 4H 2 Add O to 0.12 mL of distilled water, adjust the pH value to 9 with KOH solution, then add the ZS(60) carrier prepared above, oscillate rapidly, and let it stand for 4 h; wash with distilled water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com