Folding graphene current collector and preparation method thereof, and lithium ion battery

A technology of lithium-ion batteries and current collectors, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of limited contact area between current collectors and active materials, high cost of current collectors, and increase the contact area Compared with the bonding force, the effect of improving the rate performance and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

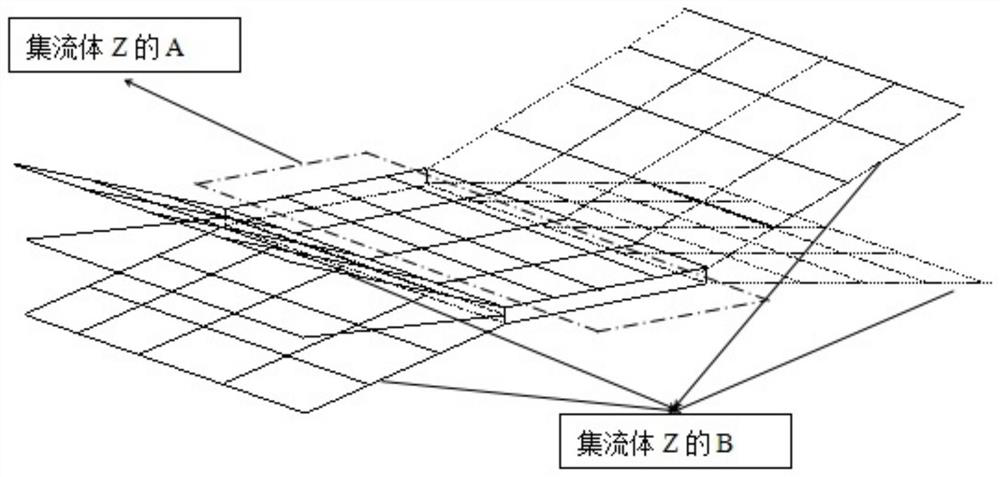

[0040] see Figure 5 , the invention provides a kind of preparation method of folded graphene current collector, described preparation method comprises the following steps:

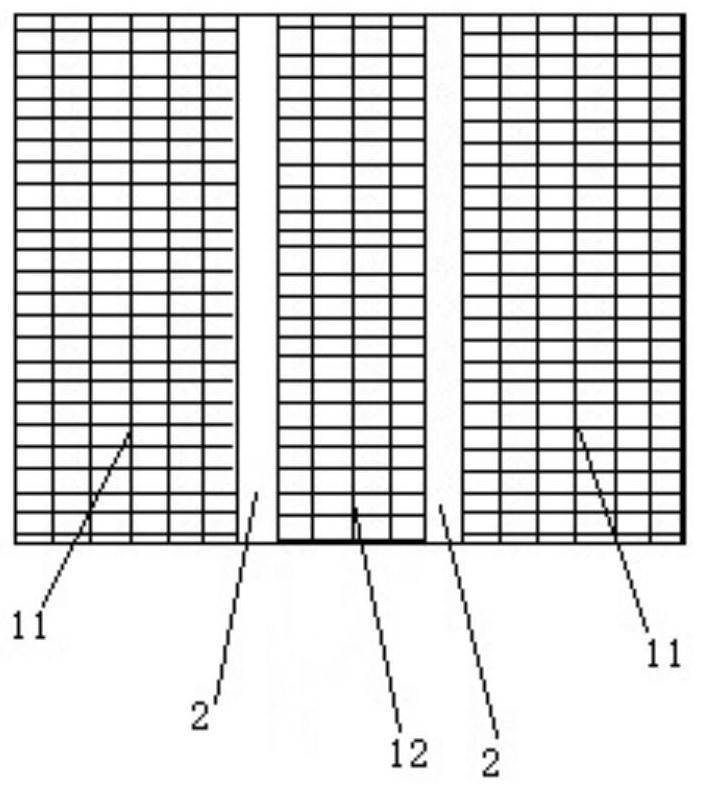

[0041]1) Preparation of braided current collector: select a metal wire with a diameter of R and an aluminum foil with a length, width and height of m*n*h, weave and grow into a network structure with a width of b, and record it as the current collector X1; first make X1 Spray graphene solution on the surface, dry it, and record it as current collector X2; then pass X2 through the conductive fiber filament solution atomization area, and dry it to obtain current collector X3;

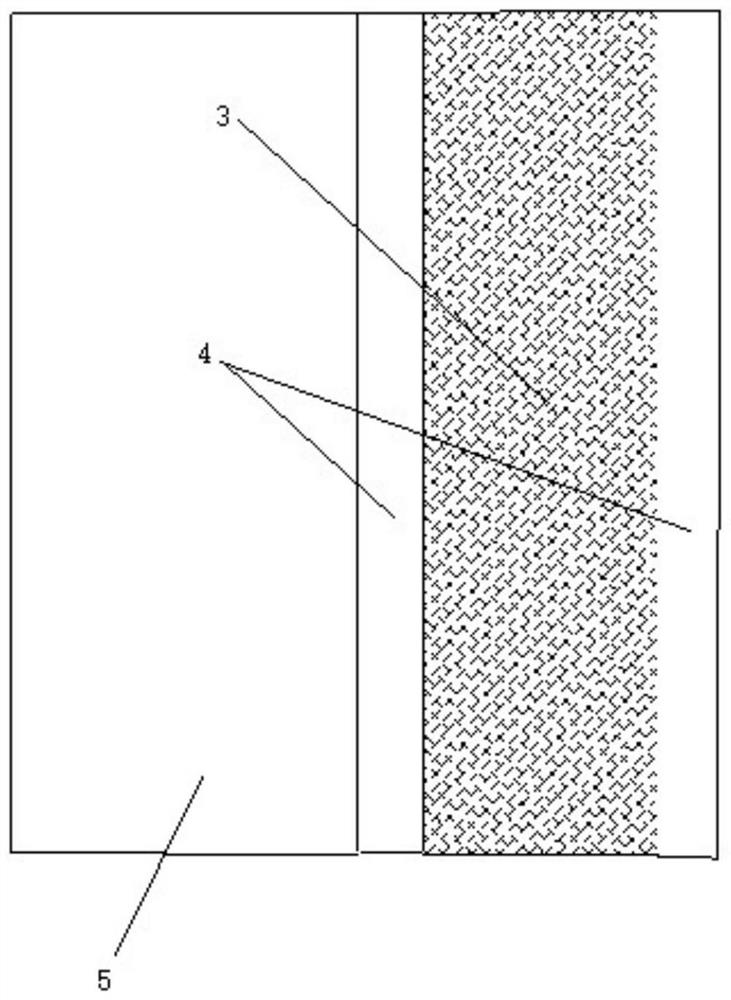

[0042] 2) Prepare a coated current collector, denoted as Y, wherein the coating is made of graphite; the non-woven part of X3 obtained in step 1) is combined with the non-coated part of Y by welding to obtain a foldable graphene current collector, It is recorded as Z; among them, Y is one layer, and the number of X3 layers is 1-100 ...

Embodiment 1

[0046] Choose a double-sided coated aluminum foil with a thickness of 0.02mm, a length of 100000mm, and a width of 300mm. The coating is graphite and the coating thickness is 0.0002mm. Choose the positive electrode LFP: (carbon black+graphene): PVDF=94: (1 +1): The positive electrode slurry prepared by 4 formulas is prepared into a positive electrode sheet with a length, width, and thickness of 150mm*150*0.2mm that can be assembled into a battery after coating, drying, rolling, and slicing; the selected thickness is 0.01mm, and the length is 100000mm, 305mm wide bare copper foil, choose negative electrode graphite: PVDF = 96: 4 negative electrode slurry, after coating, drying, rolling and slicing, etc., the length, width and thickness of the assembled battery are 152.5mm*152*0.15 mm negative pole piece; then assembled into a battery.

Embodiment 2

[0048] This embodiment provides a method for preparing a folded graphene current collector,

[0049] 1) Preparation of current collector X1: Select an aluminum wire with an R of 0.005mm and an aluminum foil with a length, width and height of 100000*10*0.005mm, such as Figure 7 As shown, weaving a current collector with a 0.02mm and b 0.02mm network structure with textile technology, the current collector is 100000mm long and 300mm wide;

[0050] 2) Preparation of current collector X3: select graphene slurry with a solid content of 5%, and spray it evenly on X1 with a spraying machine, wherein the non-woven part of X1 is not sprayed, and the sprayed current collector is dried in a drying tunnel to obtain Current collector X2, and then let X2 pass through the atomization area with 5% conductive fiber filament solution, so that the conductive fiber filaments are evenly distributed on the current collector X2, and then dry to obtain current collector X3, and wind X3; The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com