Sulfydryl-functionalized microporous polymer as well as preparation and application of sulfydryl-functionalized polymer of intrinsic microporosity (PIM-1)

A microporous polymer, functionalized technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of no adsorption effect and insufficient dispersion of mercury ions, and achieve the effect of good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

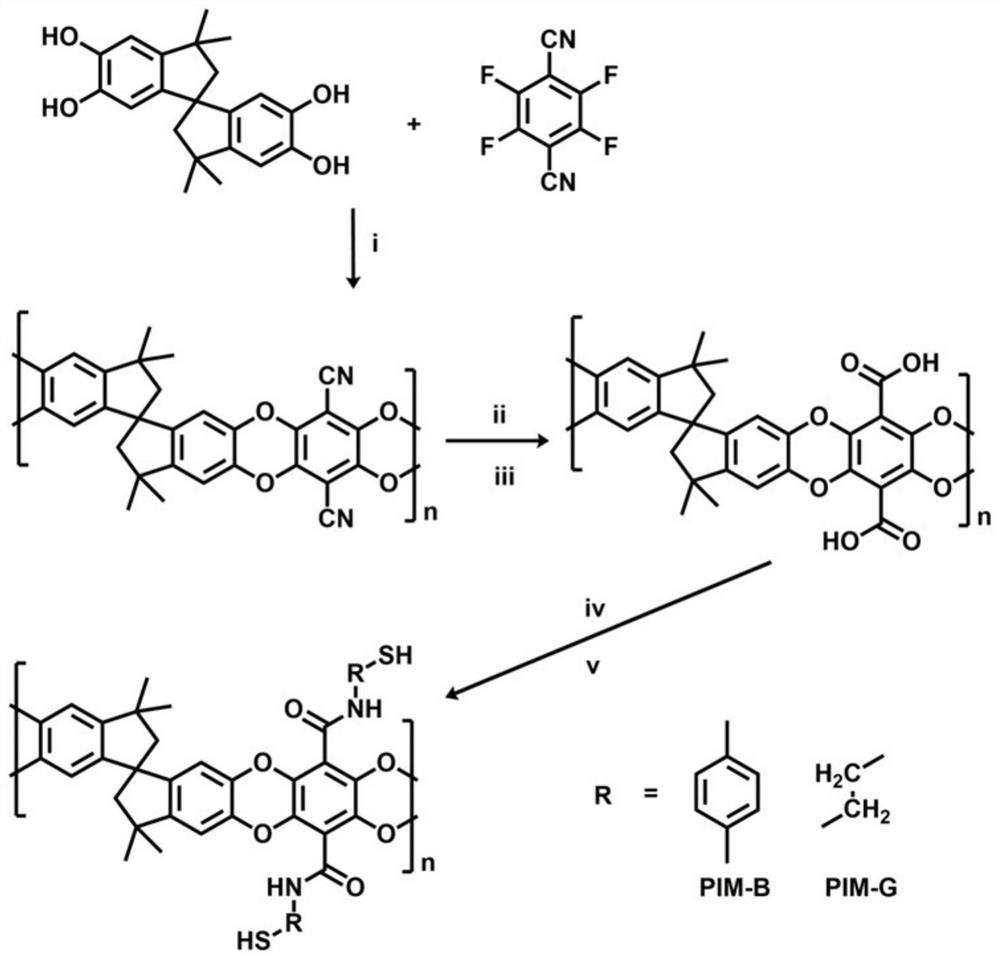

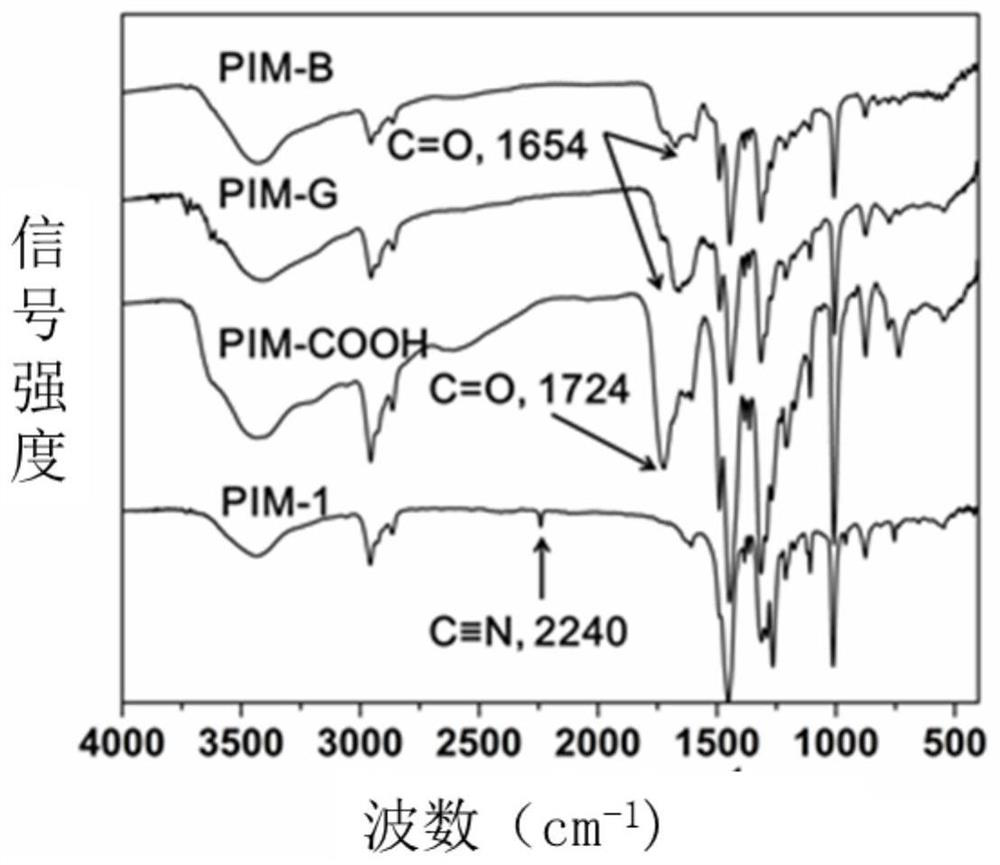

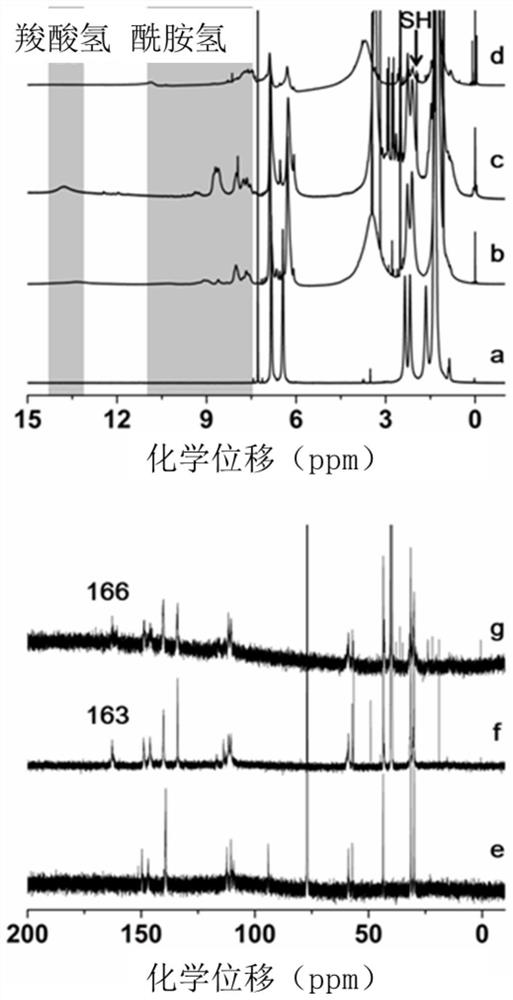

Method used

Image

Examples

Embodiment 1

[0030] 1. Add tetrafluoroterephthalonitrile (1.80g, 9.00mmol), 5,5',6,6'-tetrahydroxy-3,3',3,3'-tetramethyl-1 into a 100mL three-necked flask , 1'-spirobisindane (3.06 g, 9.00 mmol) and anhydrous potassium carbonate (4.98 g, 36.0 mmol).

[0031] 2. Add 50.0 mL of anhydrous DMF to the above flask.

[0032] 3. React the above system at 65°C for 72h under the protection of argon.

[0033] 4. After cooling to room temperature, the reaction mixture was poured into excess deionized water, and the product was obtained by suction filtration.

[0034] 5. Extract and wash the product obtained in step 4 with ethanol Soxhlet, and then dry it in vacuum at 60°C for 12 hours to obtain the final product PIM-1, with an average molecular weight of 20,000-40,000 and a specific surface of 600-1,000 m 2 / g, the pore size is 0.02-0.1nm.

[0035] 6. Weigh 1.50g of PIM-1 powder into a 250mL flask, then add 75.0mL of water, 75.0mL of ethanol and 33.8g of potassium hydroxide.

[0036] 7. Reflux the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com