Method for producing amylase by utilizing transgenic maize

A technology of transgenic corn and amylase, which is applied in the fields of biochemical equipment and methods, glycosylase, genetic engineering, etc., can solve the problems of high cost and low enzyme activity, and achieve the effect of high activity and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

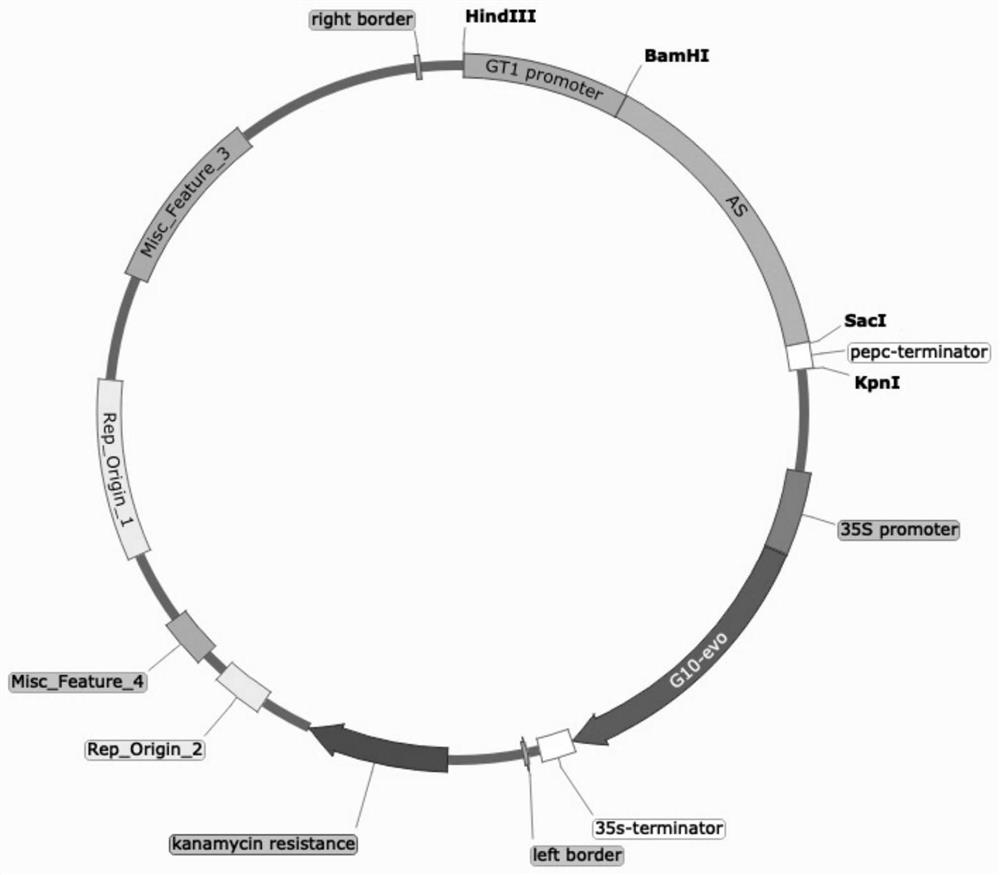

[0023] Embodiment 1, construction maize genetic transformation vector

[0024] The coding genes involved in the present invention are all artificially synthesized by Shanghai Sangong Company. The maize genetic transformation vector is constructed based on the pCambia1300 (NCBI sequence number AF234296) vector, the only difference is that the hygromycin selection gene hptII (located between the two XhoI sites) on the original pCambia1300 is replaced with the self-developed The glyphosate-resistant selection gene g10-evo (only used for the screening of positive maize transformation lines) (Zhao, Qc., Liu, Mh., Zhang, Xw. et al. Generation of insect-resistant and glyphosate-tolerant rice by introduction of a T-DNA containing two Bt insecticidal genes and an EPSPSgene.J.Zhejiang Univ.Sci.B 16,824–831(2015)), the vector was named 1300-g10evo, and stored in a -80°C refrigerator. The above-mentioned vectors are just examples, rather than the content of the present invention. Researc...

Embodiment 2

[0028] Embodiment 2, the acquisition of transgenic corn

[0029] Maize transformation methods have been relatively mature, for example, Frame et al. described the method of using Agrobacterium to transform maize (Frame et al., (2002) Plant Physiol, 129:13-22). Take the Agrobacterium tumefaciens LBA4404 strain containing the vector p1300-GT1-AS constructed by the method in Example 1, draw a plate, pick a single colony for inoculation, and prepare the Agrobacterium for transformation. Ears of Nongda 178 corn 8-10 days after pollination were taken. All immature embryos (1.0-1.5 mm in size) were collected. The above-mentioned Agrobacterium tumefaciens and immature embryos were co-cultured for 2-3 days (shading, 22° C.). Then transfer the immature embryos to the callus induction medium (containing 200mg / LTimentin, used to kill Agrobacterium, refer to (Frame et al., (2002) Plant Physiol, 129:13-22)), culture in the dark at 28°C 10-14 days. All calli were then transferred to sele...

Embodiment 3

[0032] Example 3, Determination of Amylase Activity Expressed in Transgenic Corn Seeds

[0033] Amylase activity was determined by the DNS method (Miller, 1959). The specific experimental method is as follows:

[0034] Maltose standard solution: prepare 10mM maltose standard solution with deionized water;

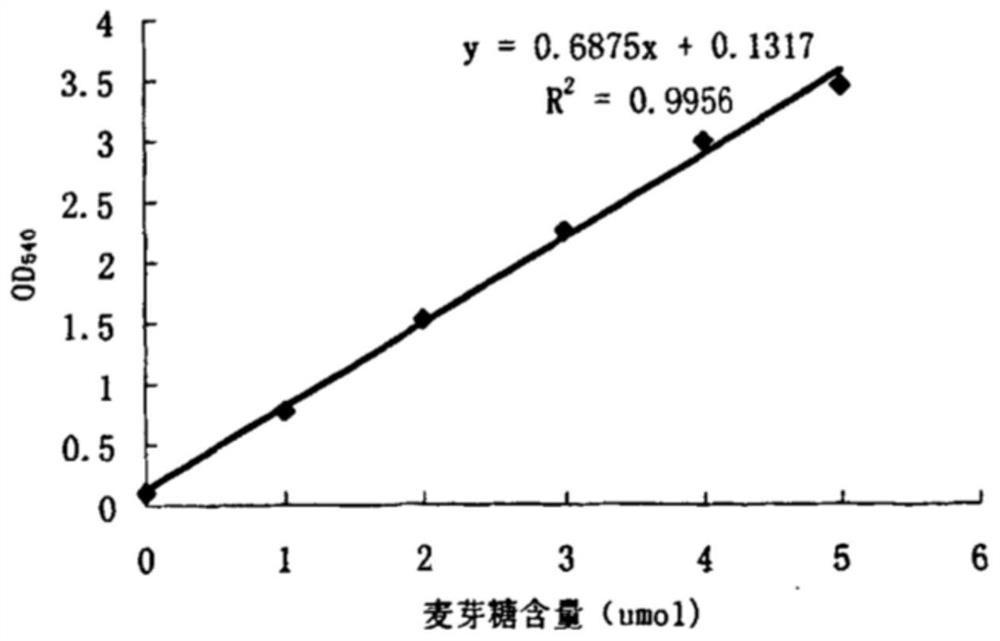

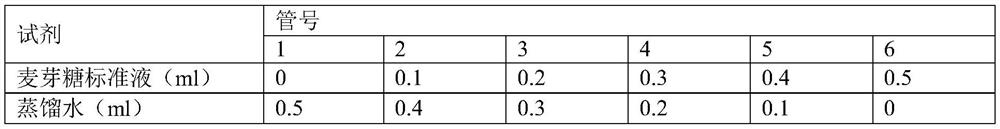

[0035] To make the maltose standard curve, add different reagents according to the following table 1.

[0036] The making of table 1 maltose standard curve

[0037]

[0038]

[0039] Shake well and boil in water for 5 minutes, take it out and cool it down, measure the absorbance at 540nm wavelength, draw the standard curve with the maltose content as the abscissa and the absorbance as the ordinate, such as figure 2 shown.

[0040] Preparation of enzyme solution: take 10 mg of corn seeds expressing amylase and add 1 ml of buffer solution (20 mM sodium acetate, pH 5.4, 250 mM NaCl) to grind, and the mixed solution after grinding is the enzyme solution.

[0041] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com