Pulverizing system and process for reducing ash and improving quality of circulating materials in medium-speed coal pulverizers in coal-fired power plants

A pulverizing system and coal pulverizer technology, which is applied in the direction of block/powder fuel preparation, fuel supply, solid fuel pretreatment, etc., can solve the problems such as the difficult operation of circulating material diversion, and achieve the reduction of the internal circulation rate of the mill and the wear, reduce pollutant emissions, and improve the quality of qualified pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

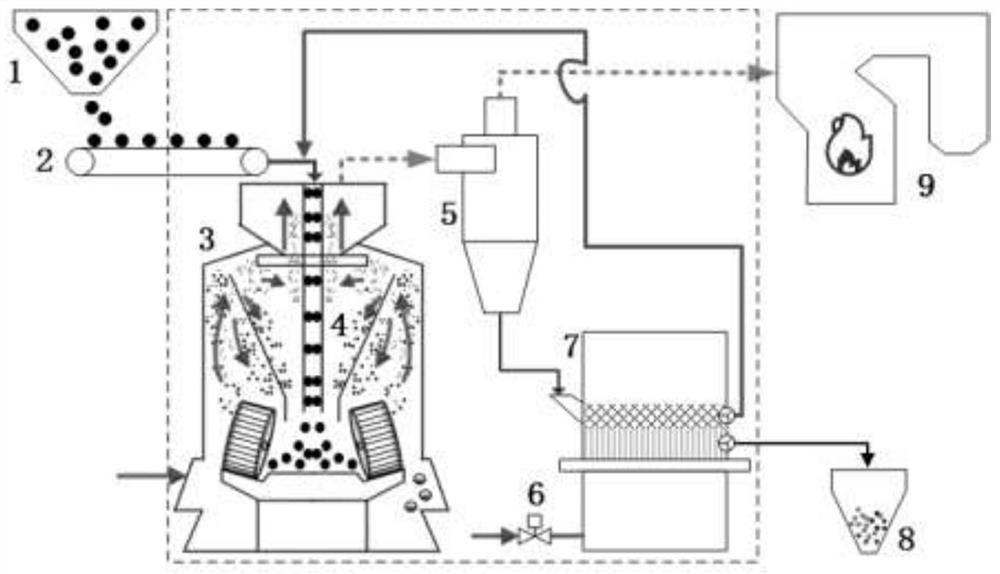

[0022] figure 1 Shown is a coal-fired power plant medium-speed pulverizer pulverization process for reducing ash and upgrading materials, mainly including raw coal bunker 1, belt conveyor 2, medium-speed pulverizer 3, pulverized coal classifier 4, cyclone classification device 5, pulsating valve 6, pulsating air flow sorting bed 7, gangue bin 8, boiler 9, the feed port of the medium-speed coal mill 3 is connected with the discharge port of the raw coal bunker 1 through the belt conveyor 2, and the The discharge port of the medium-speed coal mill 3 is connected to the feed port of the cyclone classifier 5, the overflow port of the cyclone classifier 5 is connected to the feed port of the boiler 9, and the underflow port of the cyclone classifier 5 is connected to the pulsating The air flow separation bed 7 feed port is connected, the clean coal discharge port of the pulsating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com