Ordered porous composite material as well as preparation method and application thereof

A porous composite material and reaction technology, applied in the direction of additive processing, pharmaceutical formulations, prostheses, etc., can solve the problems of long degradation cycle, low biological activity, low mechanical strength and potential immunogenicity, and achieve the effect of accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

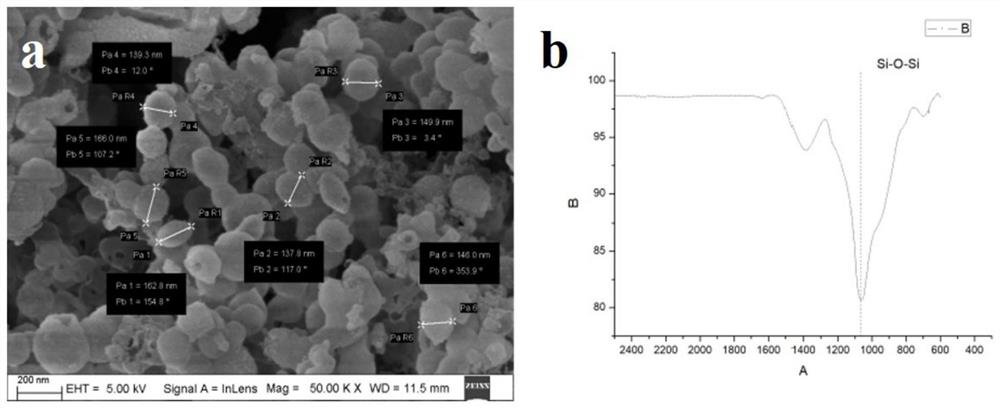

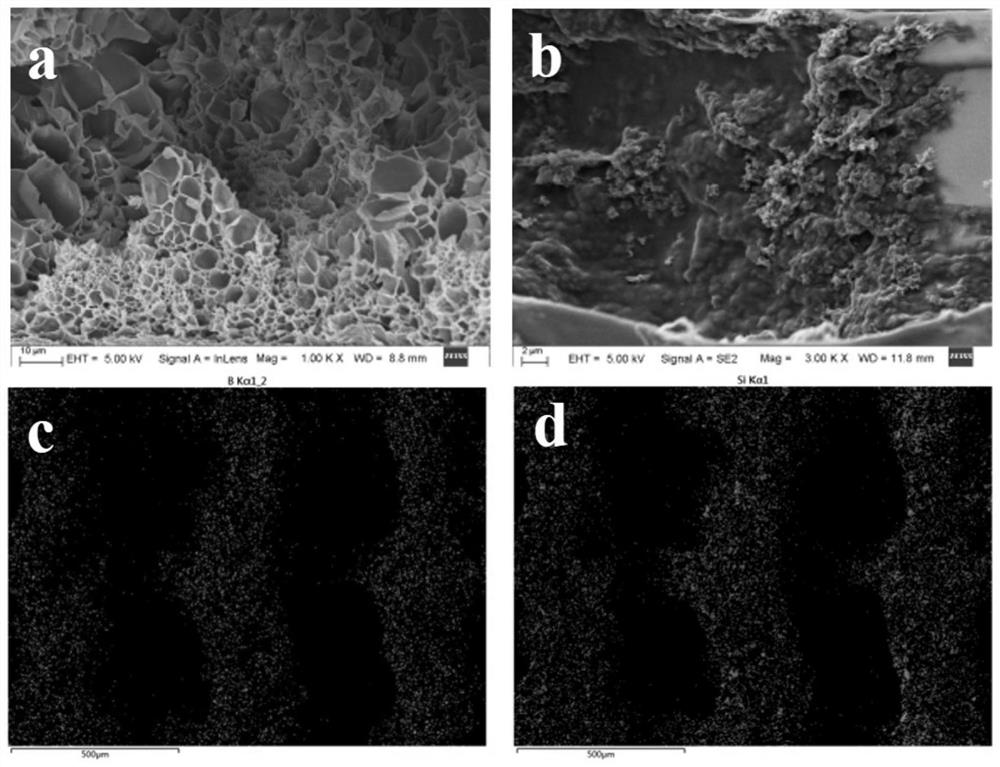

[0082] This embodiment provides an ordered porous composite material, including photosensitive silk fibroin and borosilicate bioactive glass dispersed in the photosensitive silk fibroin. Based on the weight of the ordered porous composite scaffold as 100%, the weight of the borosilicate bioactive glass is 1%.

[0083] Wherein, borosilicate bioactive glass has the following composition:

[0084] 14SrO 8CaO 8MgO 38B 2 o 3 ·2P2 o 5 ·30SiO2 2 .

[0085] The particle size range of the borosilicate bioactive glass is 100-300nm.

[0086] The borosilicate bioactive glass also includes ZnO, and the molar content of ZnO is 1%.

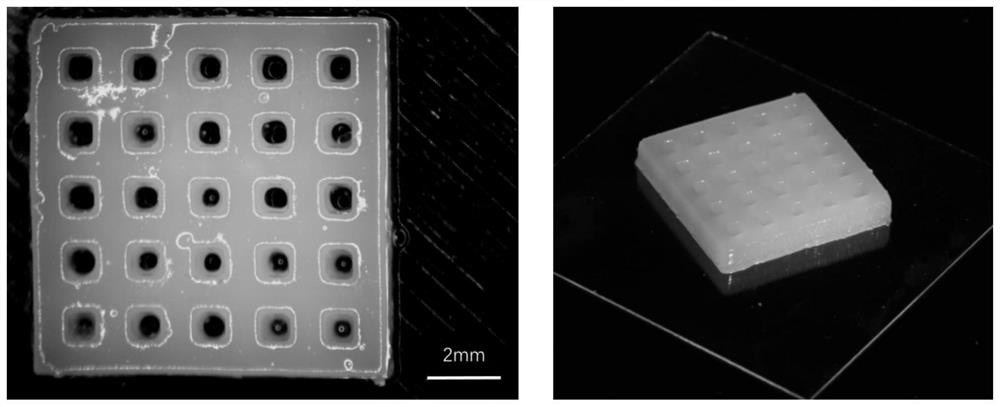

[0087] The pore size of the ordered porous composite material is 50-300 μm; the pore density is 50-300 ppi.

Embodiment 2

[0089] This embodiment provides an ordered porous composite material. The difference from Example 1 is that, based on the weight of the ordered porous composite support as 100%, the micro-nano borosilicate bioactive glass 3% by weight.

[0090] Among them, the micro-nano borosilicate bioactive glass has the following composition:

[0091] 10SrO 10CaO 10MgO 38B 2 o 3 ·2P 2 o 5 ·30SiO2 2 ,

[0092] The particle size range of the bioactive glass is 30-100nm.

[0093] The borosilicate bioactive glass also includes Ag 2 O, Ag 2 The molar content of O is 0.25%.

[0094] The pore size of the ordered porous composite material is 200-300 μm; the pore density is 200-300ppi.

Embodiment 3

[0096] This embodiment provides an ordered porous composite material. The difference from Example 1 is that, based on the weight of the ordered porous composite support as 100%, the micro-nano borosilicate bioactive glass 5% by weight.

[0097] Among them, the micro-nano borosilicate bioactive glass has the following composition:

[0098] 20CaO 8MgO 27B 2 o 3 ·4P 2 o 5 41SiO2 2 ,

[0099] The particle size range of the bioactive glass is 50-250nm.

[0100] The borosilicate bioactive glass also includes Ag 2 O, CuO, Ag 2 The molar content of O was 0.2%, and the molar content of CuO was 0.3%.

[0101] The pore size of the ordered porous composite material is 100-200 μm; the pore density is 100-200 ppi.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com