Acid-resistant glass powder for end coating of silver paste and preparation method thereof

A technology of glass powder and silver paste, which is applied in the direction of weighing by removing certain components, can solve the problem of insufficient acid resistance of glass powder, and achieve the effect of excellent electrical properties, good acid resistance and dense coating of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

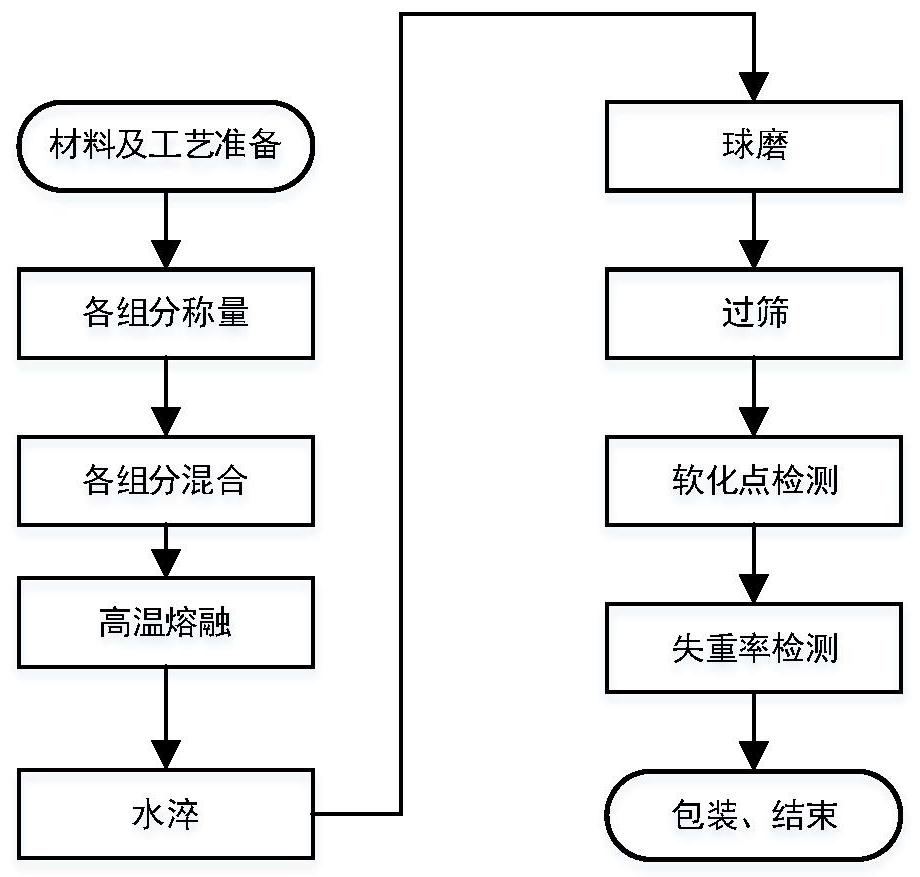

Method used

Image

Examples

Embodiment 1

[0043] A kind of acid-resistant glass powder, the preferred weight percentage is composed of:

[0044] SiO 2 20%~60%, Na 2 CO 3 10%~50%, K 2 CO 3 0.5%~8%, ZnO 15%~30%, B 2 o 3 1%~20%, CaO 1%~8%, Al 2 o 3 0.5% to 5%, TiO 2 1%~10%, ZrO 2 0.5%~8%, Na 2 CO 3 / K 2 CO 3 The molar ratio is 20~60, Na 2 CO 3 / B 2 o 3 The molar ratio of >1.

Embodiment 2

[0046] 1. The raw material composition is by weight percentage:

[0047] SiO 2 40%, Na 2 CO 3 30%, K 2 CO 3 1%, ZnO 20%, B 2 o 3 2%, CaO 3%, Al 2 o 3 1%, TiO 2 2%, ZrO 2 1%.

[0048] 2. Preparation method:

[0049] (1) Take each raw material according to the weight percentage of each component;

[0050] (2) Mix the weighed raw materials with a conventional powderer;

[0051] (3) Put the mixed mixture into a crucible, and then put it into a box-type high-temperature furnace with a furnace temperature of 1200 ° C ~ 1300 ° C, and keep it warm for 1 ~ 2 hours;

[0052] ⑷ Pour the molten glass into cold water and quench it;

[0053] (5) Put the glass particles into the ball mill for ball milling;

[0054] ⑹Sieve the ball-milled glass powder according to the conventional method;

[0055] ⑺ Use a synchronous thermal analyzer to detect the softening point of the glass powder, and confirm that the softening point of the glass powder is 550°C to 750°C;

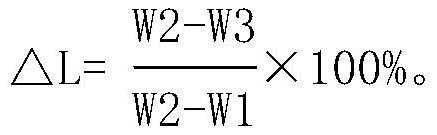

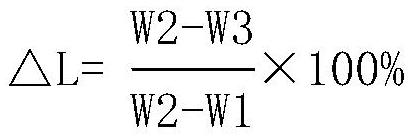

[0056] ⑻ Detect...

Embodiment 3

[0062] 1. The raw material composition is by weight percentage:

[0063] SiO 2 40%, Na 2 CO 3 35%, K 2 CO 3 1%, ZnO 15%, B 2 o 3 2%, CaO 3%, Al 2 o 3 1%, TiO 2 2%, ZrO 2 1%.

[0064] 2. Preparation method:

[0065] (1) Take each raw material according to the weight percentage of each component;

[0066] (2) Mix the weighed raw materials with a conventional powderer;

[0067] (3) Put the mixed mixture into a crucible, and then put it into a box-type high-temperature furnace with a furnace temperature of 1200 ° C ~ 1300 ° C, and keep it warm for 1 ~ 2 hours;

[0068] ⑷ Pour the molten glass into cold water and quench it;

[0069] (5) Put the glass particles into the ball mill for ball milling;

[0070] ⑹Sieve the ball-milled glass powder according to the conventional method;

[0071] ⑺ Use a synchronous thermal analyzer to detect the softening point of the glass powder, and confirm that the softening point of the glass powder is 550°C to 750°C;

[0072] ⑻ Detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com