Multiphase rubidium titanate functional ceramic material and preparation method thereof

A technology of functional ceramics and multiphase ceramics is applied in the field of multiphase rubidium titanate functional ceramic materials and their preparation to achieve the effects of low cost, long cycle life and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of multiphase rubidium titanate functional ceramic powder by mechanical-chemical synthesis + solid-phase firing method

[0036] Step 1. Dry fine precursor preparation

[0037] According to Rb 2 Ti n O 2n+1 (here, n=2) with a stoichiometric molar ratio Ti:Rb≈n:2, weigh an appropriate amount of dry titanium dioxide (TiO 2 ) and rubidium carbonate (Rb 2 CO 3 ) powder is used as titanium source and rubidium source, and the actual ratio deviation of the two is controlled within ±5%, and then the two are initially mixed and then crushed and mixed by a vibrating mill in a mechanical-chemical manner for 30 minutes.

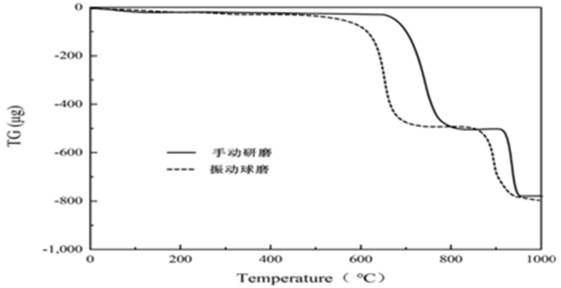

[0038] figure 1 The thermogravimetric TG curve of the precursor powder obtained by the above method is compared with the thermogravimetric TG curve of the control product obtained by hand grinding and mixing for 30 minutes only. It can be seen from the figure that the temperature of starting pyrolysis and weight loss of the precursor powder obta...

Embodiment 2

[0046] Preparation of multi-phase rubidium titanate functional ceramic powder by liquid-phase synthesis and solid-phase firing

[0047] Step 1. Dry fine precursor preparation

[0048] According to Rb 2 Ti n O 2n+1 (here, n=4) with a stoichiometric molar ratio Ti:Rb≈n:2, weigh an appropriate amount of dry titanium dioxide (TiO 2 ) and rubidium carbonate (Rb 2 CO 3 ) powder is used as titanium source and rubidium source, and the actual ratio deviation of the two is controlled within ±5%, and then placed in the flask and then added with deionized water 4 times the weight of titanium dioxide to mix evenly; use an evaporator to concentrate, dry and solidify, The powder obtained by grinding is the precursor.

[0049] Step 2. Ceramic powder firing

[0050] Take an appropriate amount of the precursor powder obtained by the above steps, put it into a crucible and place it in a heat treatment furnace, and burn it in the air at 870° C. for 1.5 hours.

[0051] When cooled to near ...

Embodiment 3

[0056] Preparation of multi-phase rubidium titanate functional ceramic powder by solid-phase mixing + firing method

[0057] Step 1. Precursor Preparation

[0058] Titanium oxide (TiO 2 ) and rubidium carbonate (Rb 2 CO 3 ) The powders are titanium source and rubidium source, respectively bake at 100℃ for 24 hours to make them completely dehydrated, take n=3 and according to Rb 2 Ti n O 2n+1 The stoichiometric molar ratio of Ti:Rb≈n:2 is to weigh an appropriate amount of titanium source and rubidium source (the actual ratio deviation of the two is controlled within ±5%), put them in an agate mortar and grind for 20 minutes, and the obtained powder is reused A 10-ton press was pressed for 5 minutes to obtain a precursor.

[0059] Step 2. Preparation of ceramic powder

[0060] The particles thus generated are placed in a platinum crucible and placed in a heat treatment furnace, and heat treated in the air according to the following procedure: raise the temperature to 315°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com