Heavy metal polluted farmland restoration straw gasification combustion and heat energy grain drying coupling technology

A heavy metal and straw technology, applied in drying, drying machine, combustion type and other directions, can solve the problems of increasing the economic burden of farmers, unable to achieve industrialization, low calorific value, etc., to save the cost of drying rice, high feasibility and economy, the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

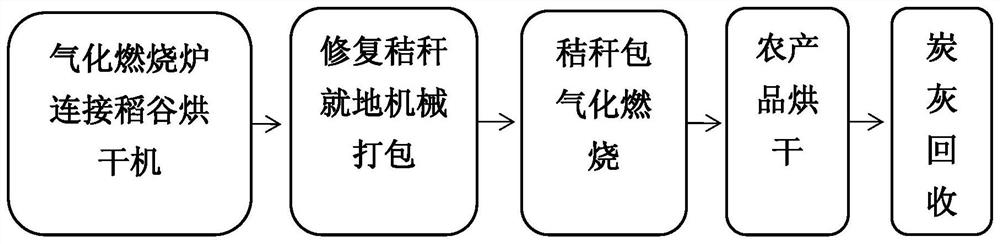

Method used

Image

Examples

Embodiment 1

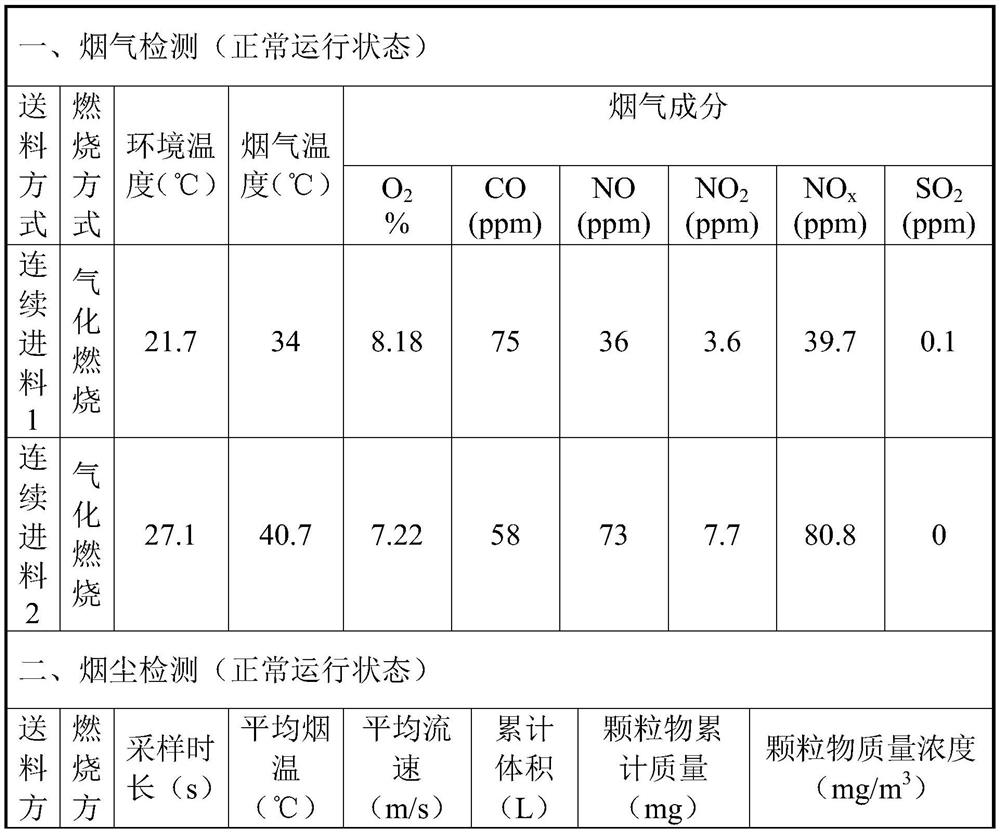

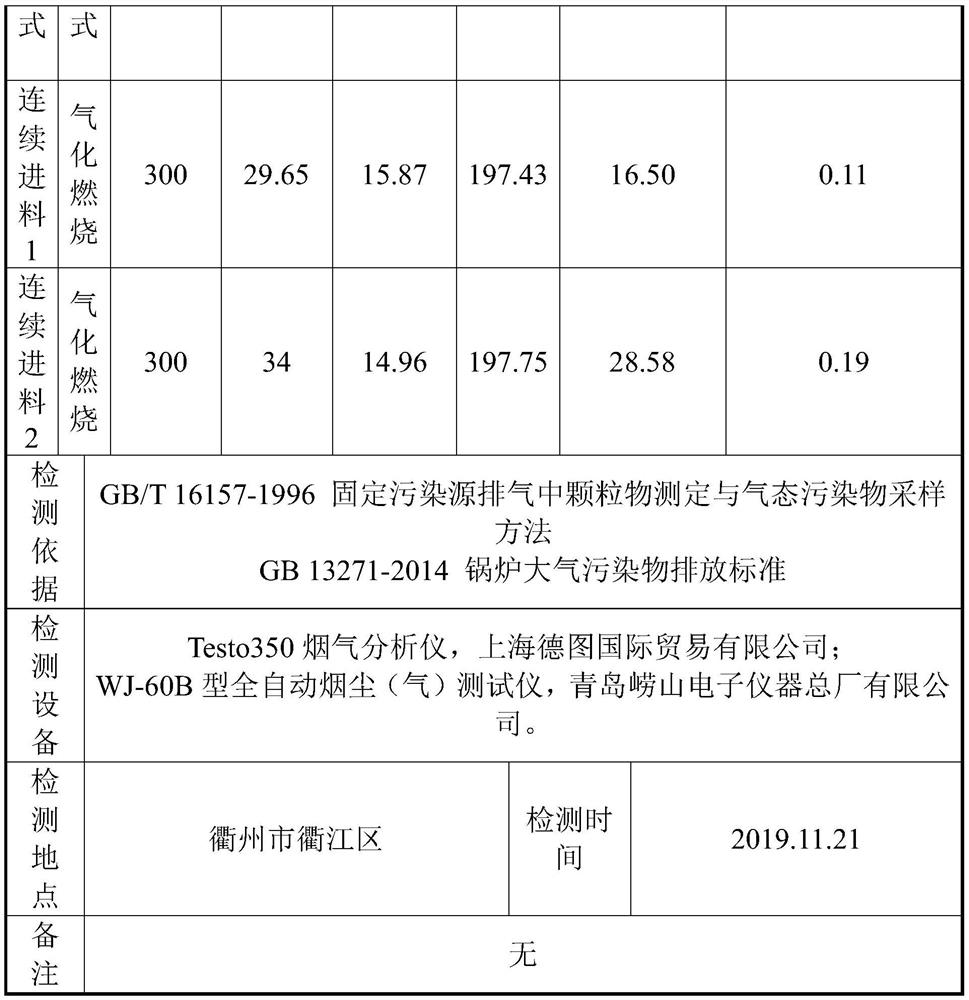

[0037] Test location: a Cd heavy metal-polluted farmland production-side restoration project demonstration area in Qujiang District, Quzhou City, Zhejiang Province.

[0038] The demonstration area covers an area of 100 mu, the average concentration of Cd pollution is 0.76ppm, the soil pH (1: 2.5) is 4.69, and the average concentration of Cd pollution in rice straw is 0.34ppm.

[0039] Establish a gasification heat utilization system: build the gasification combustion furnace produced by Zhejiang Wenxin Thermal Energy Technology Co., Ltd. and its matching bag filter and electric conveyor belt in the grain drying base, and then use the matching heat converter to dry the four grains machine connection. The system is assembled from existing equipment.

[0040] On-site mechanical packaging of rice straw: the farmland in the restoration demonstration area is about 3 kilometers away from the drying base. The repaired rice straw is packed with a straw baler after the single-crop ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com