Moisture-resistant nano Zn-In2O3 sensor material with three-dimensional structure as well as preparation method and application of same

A zn-in2o3, three-dimensional structure technology, applied in the direction of material analysis, material analysis by electromagnetic means, instruments, etc., can solve the problems of hindering metal oxide semiconductor gas sensors, long response and recovery time, poor stability, etc. Achieve the effects of improving gas sensitivity performance, making raw materials cheap, and providing gas contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of anti-moisture nanometer Zn-In 2 o 3 A method for preparing a three-dimensional structure sensor material, comprising the following steps:

[0036] 1) Prepare a mixed solution with 13 mL absolute ethanol and 3 mL glycerin.

[0037] 2) Add 0.3 g of indium chloride into the above mixed solution, stir to dissolve evenly, and form mixed solution 1;

[0038] 3) Disperse 0.2 g of zinc acetate in a mixed solution of 13 mL of absolute ethanol and 5 mL of sodium hydroxide (0.3 mmol / L) to form a mixed solution II;

[0039] 4) Mix the two mixed solutions obtained above evenly and put them into a 50 mL polytetrafluoroethylene substrate, and perform a solvothermal reaction at 170°C for 8 hours;

[0040] 5) After collecting, washing, and drying the reacted materials, put the powder in a muffle furnace for sintering at 500°C for 2 hours to obtain a yellow powder, which is Zn-In 2 o 3 Nanostructured materials (denoted as Zn / In2 o 3 (1 / 1));

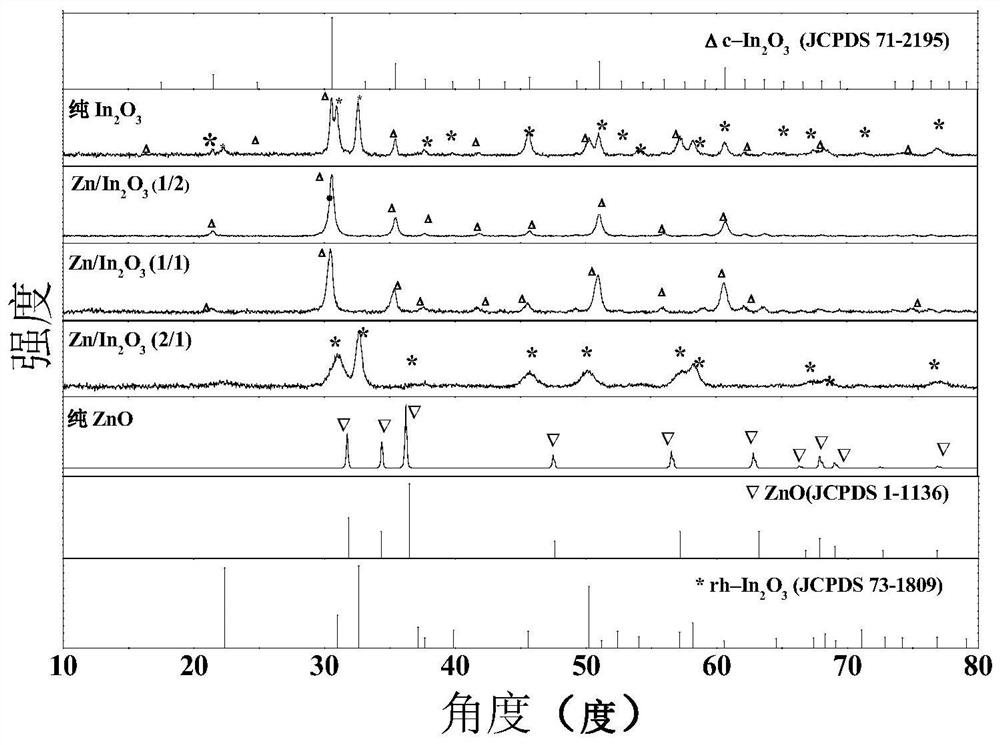

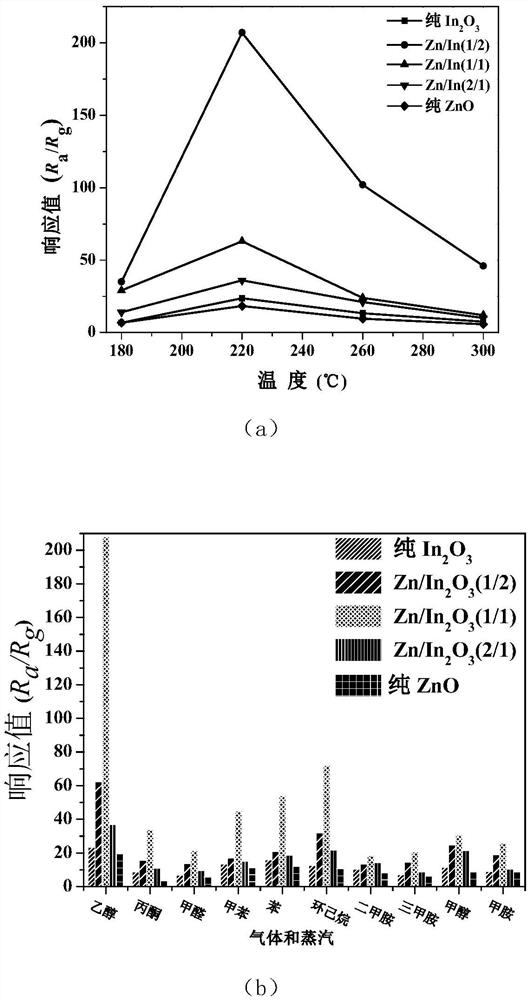

[0041] The prepared Zn-In 2...

Embodiment 2

[0043] Same operation as Example 1, the difference is: the mol ratio of indium chloride and zinc acetate is 2 / 1, the concentration of sodium hydroxide solution is 0.1mmol / L, and the volume ratio of dehydrated alcohol and glycerol mixed solution is 10 , the hydrothermal time is 24h, and the reaction temperature is 100°C (denoted as Zn / In 2 o 3 (1 / 2)).

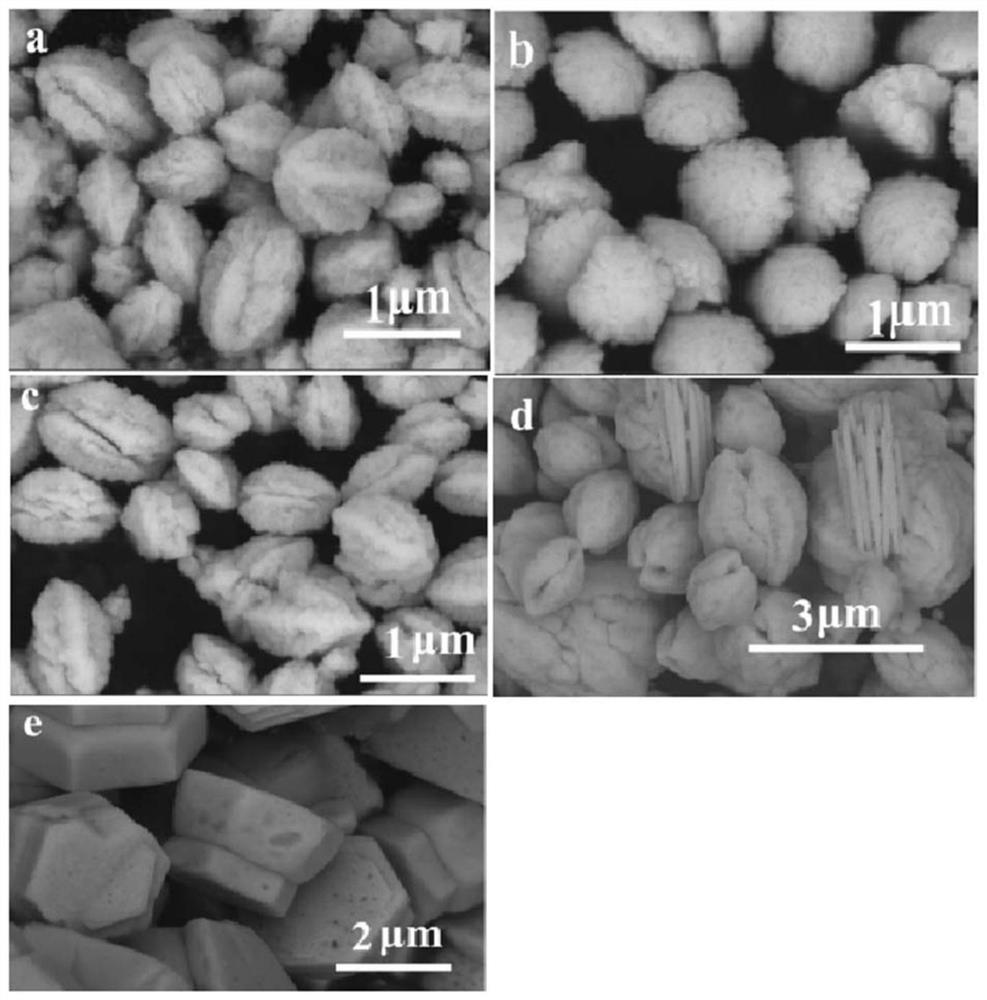

[0044] Adopt SEM to characterize the morphology of the prepared sample in this embodiment, as image 3 shown.

Embodiment 3

[0046] Same operation as Example 1, the difference is that the molar ratio of indium chloride and zinc acetate is 1 / 2, the concentration of sodium hydroxide solution is 1mmol / L, the volume ratio of absolute ethanol and glycerin mixed solution is 2, hydrothermal The time is 2h, and the reaction temperature is 200°C. (denoted as Zn / In 2 o 3 (2 / 1)).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com