OLED structure capable of improving packaging capability and preparation method

A technology of capability and encapsulation layer, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems affecting product yield level, easy cracking and disintegration of film layer, introduction of water vapor and oxygen, etc., to achieve reduction in plasma mode , Increase the light extraction efficiency, reduce the effect of surface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

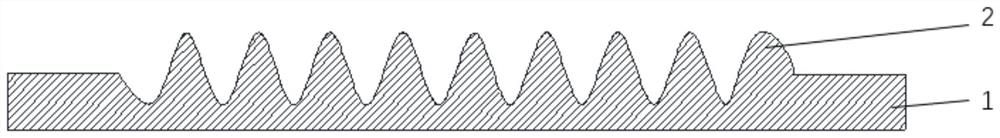

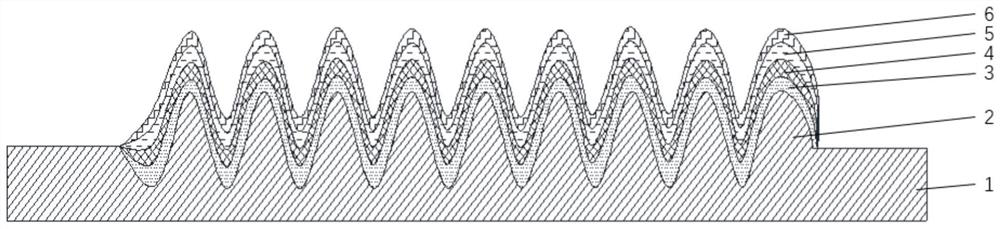

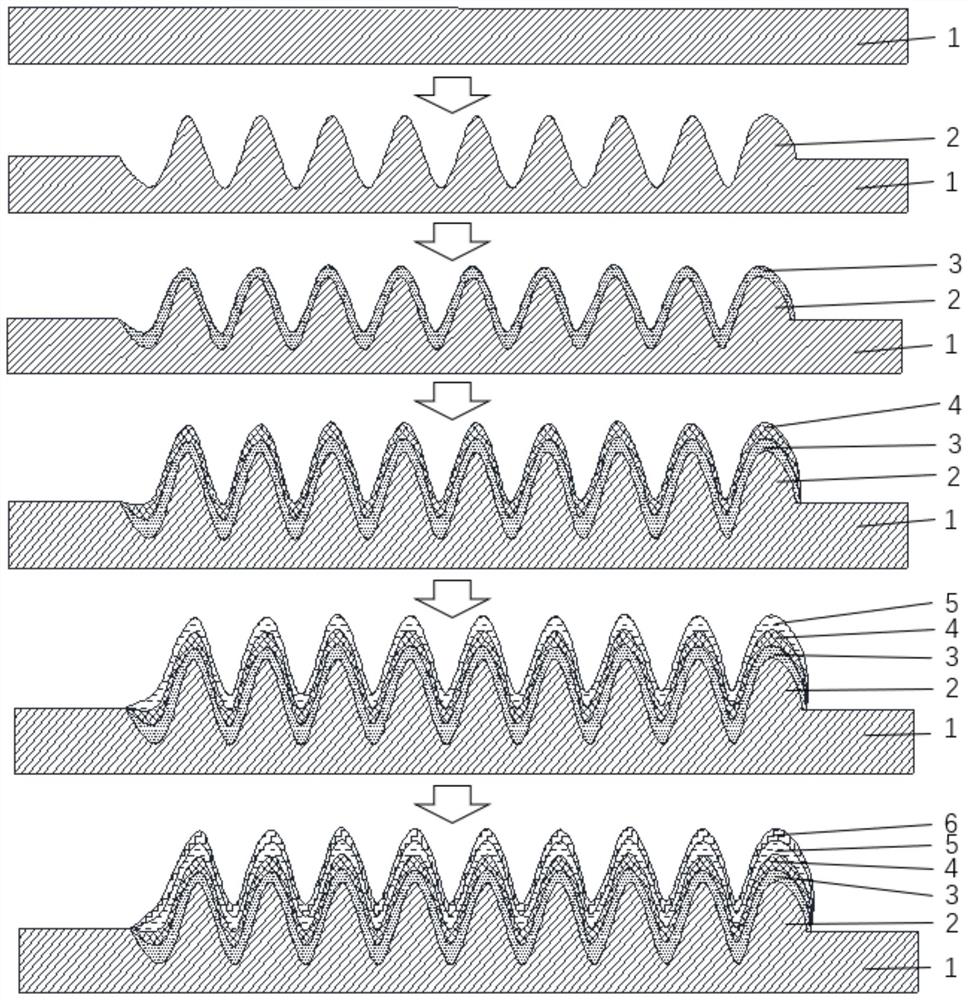

[0042] see image 3 , taking the substrate 1 in a vacuum reaction chamber with a 13.56 MHz plasma radio frequency source, adopting C4F8 and SF6 alternate passivation and etching methods, etching a surface structure with concave-convex lines on one side to form a substrate concave-convex structure 2 The height of the convex part is 6 μm, and the depth of the recess is 5 μm. Of course, besides the etching method in the embodiment, etching methods such as photolithography can also be used, which is not limited by this embodiment.

[0043] The vacuum degree is controlled to 1×10-5 Pa, and the evaporation temperature is 1300 °C, and an aluminum anode 3 with a thickness of 220 nm is prepared on the concave-convex surface of the substrate. The anode 3 is a non-transparent metal, which has high light reflection efficiency and corrosion resistance, improves the light extraction efficiency of the OLED structure, and enhances the brightness of the product.

[0044] Keep the vacuum degre...

Embodiment 2

[0050] see image 3 , taking the substrate in a vacuum reaction chamber with a 13.56 MHz plasma radio frequency source, adopting C4F8 and SF6 alternate passivation and etching methods, etching a surface structure with concave and convex lines on one side to form a substrate concave and convex structure 2, and the height of the convex part is is 1 μm, and the depth of the depressed portion is 10 μm.

[0051] Control the vacuum degree below 1 Pa, use argon and oxygen as the process gas, the specific flow rate of argon gas is 50 sccm, the flow rate of oxygen gas is 0.7 sccm, and magnetron sputtering is used to prepare titanium anode 3 on the concave-convex surface of the substrate with a thickness of 100 nm , the anode 3 is a non-transparent metal, which has high light reflection efficiency and corrosion resistance, and the low light-emitting layer is used to improve the light extraction efficiency of the OLED structure, enhance the brightness of the product and keep the vacuum d...

Embodiment 3

[0056] see image 3 , take the substrate and match it with a 13.56 MHz plasma radio frequency source in a vacuum reaction chamber, etch a surface structure with concave-convex lines on one side to form a substrate concave-convex structure. The height of the convex part is 10 μm, and the depth of the concave part is 1 μm.

[0057] The vacuum degree is controlled to 1×10-5 Pa, and the evaporation temperature is 1300 °C, and an aluminum anode 3 with a thickness of 220 nm is prepared on the concave-convex surface of the substrate. The anode 3 is a non-transparent metal with high light reflection efficiency and corrosion resistance, and the low light-emitting layer is used to improve the light extraction efficiency of the OLED structure and enhance the brightness of the product.

[0058] Keeping the degree of vacuum below 1×10-5 Pa, the hole injection layer, the hole transport layer, the light emitting layer, the electron transport layer, and the electron injection layer are sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com