Super water-absorbing resin continuously prepared by reversed-phase suspension polymerization

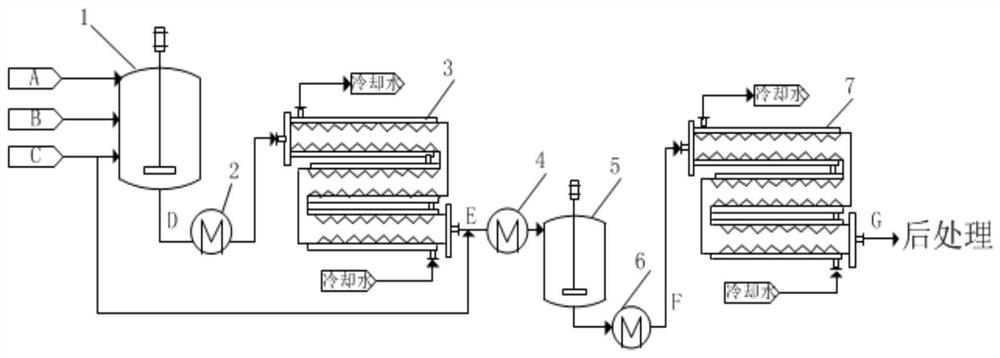

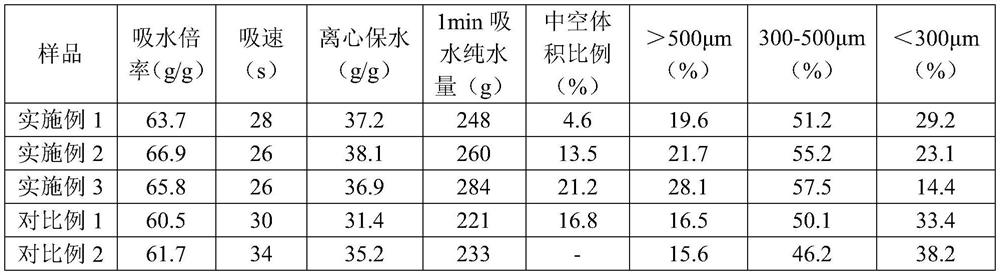

A superabsorbent resin and suspension technology, applied in the field of water absorbent resin, can solve the problems of low product performance stability, poor customer experience, limited marketing, etc., achieve easy control of flow rate and temperature, and improve water absorption rate performance , to solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Step a:

[0085] Add 3000g of acrylic acid into a small test kettle, add 4100g of 32% NaOH, 2550g of deionized water, 22.5g of trimethylolpropane, and 5.75g of sodium persulfate, stir for 15 minutes to neutralize the acid and alkali and mix it uniformly, then Cool and control the temperature to 25°C to obtain an aqueous acrylic acid solution for later use.

[0086] Add 10,000g of n-heptane into a small test kettle and heat it. After the temperature rises to 50°C, add 120.7g of sucrose fatty acid ester to it, and then control the temperature to 50°C to obtain n-heptane with dispersant dissolved in it for later use.

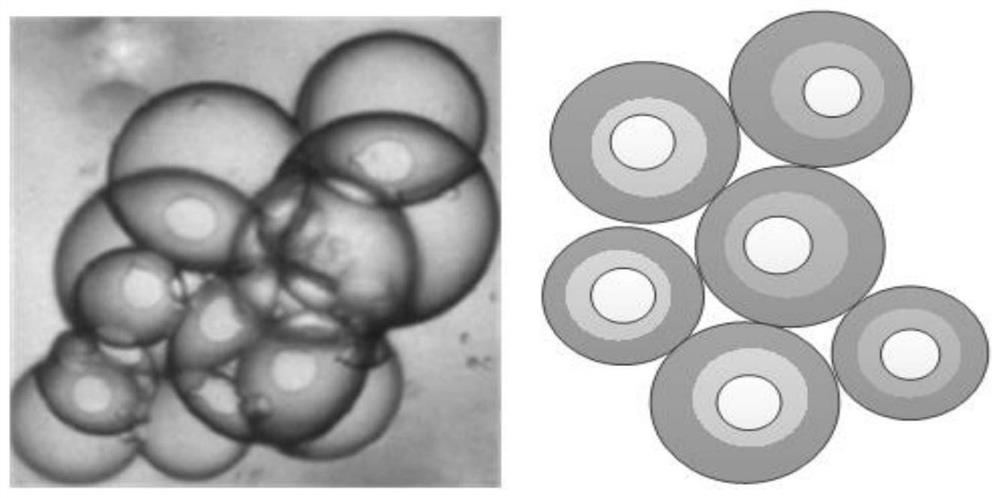

[0087] Add acrylic acid aqueous solution into the suspension tank at 448g / min using a peristaltic pump, and continuously add n-heptane into the suspension tank at a flow rate of 1452.9g / min using a peristaltic pump. Add it into the suspension tank, adjust the stirring speed of the suspension tank to control the particle size of the suspended particles to 68...

Embodiment 2

[0096] Step a:

[0097] Add 3000g of acrylic acid into a small test kettle, add 4100g of 32% NaOH, 2550g of deionized water, 0.6g of glycerol diglycidyl ether, and 5.75g of potassium persulfate, and stir for 15 minutes to neutralize the acid and alkali and mix it evenly. Then cool and control the temperature to 25° C. to obtain an aqueous acrylic acid solution for future use.

[0098] Add 10,000g of n-heptane into a small test kettle and heat it. After the temperature rises to 50°C, add 10.75g of octadecyl monophosphate to it, and then control the temperature to 50°C to obtain n-heptane dissolved in a dispersant for use.

[0099] Add acrylic acid aqueous solution into the suspension tank at 448g / min using a peristaltic pump, and continuously add n-heptane into the suspension tank at a flow rate of 818.4g / min using a peristaltic pump, and at the same time, add polystyrene particles with a particle size of 38μm at a flow rate of 50g / min Add it into the suspension tank, adjust t...

Embodiment 3

[0107] Step a:

[0108] Add 2400g of acrylic acid into a small test kettle, add 3500g of 32% NaOH, 4270g of deionized water, 0.6g of ethylene glycol diglycidyl ether, and 22.75g of ammonium persulfate, stir for 15 minutes to neutralize the acid and alkali and mix it evenly , and then cooled to control the temperature to 25°C to obtain an aqueous acrylic acid solution for later use.

[0109] Add 10,000g of cyclohexane into a small test kettle and heat it. After the temperature rises to 50°C, add 60.75g of sucrose fatty acid ester into it, and then control the temperature to 50°C to obtain cyclohexane dissolved in dispersant for use.

[0110] Add acrylic acid aqueous solution into the suspension tank at 448g / min using a peristaltic pump, and continuously add n-heptane into the suspension tank at a flow rate of 818.4g / min using a peristaltic pump. Add it into the suspension tank, adjust the stirring speed of the suspension tank to control the particle size of the suspended parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com