Silicon-doped iron-based polyanion compound and its preparation method and application

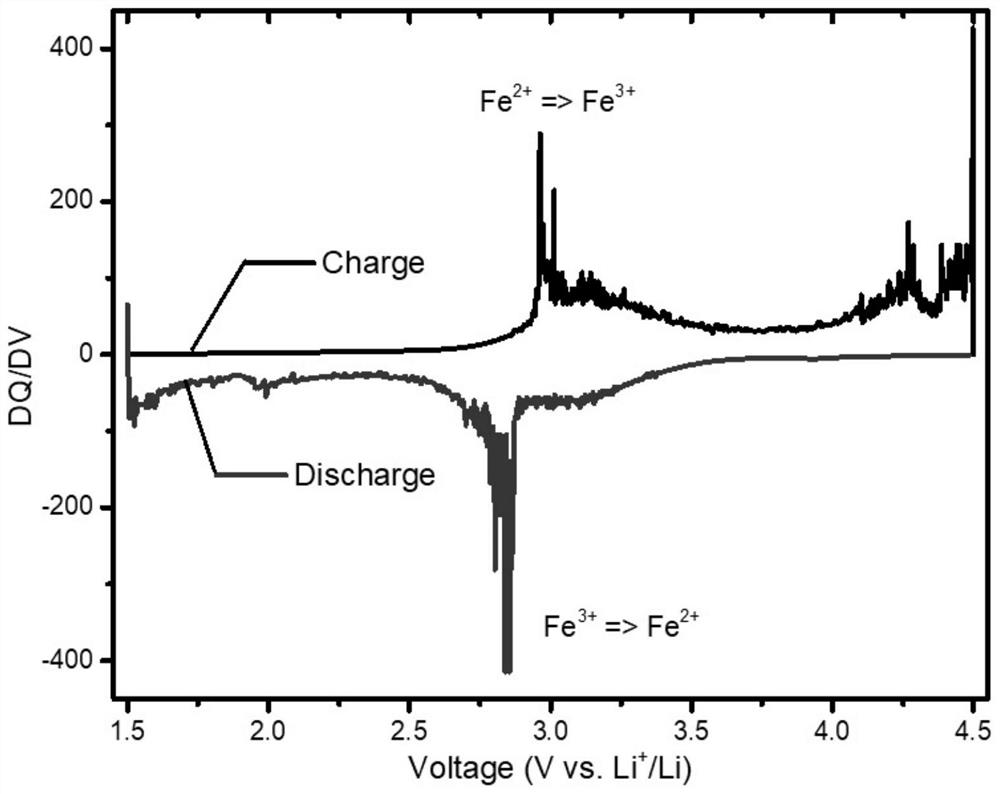

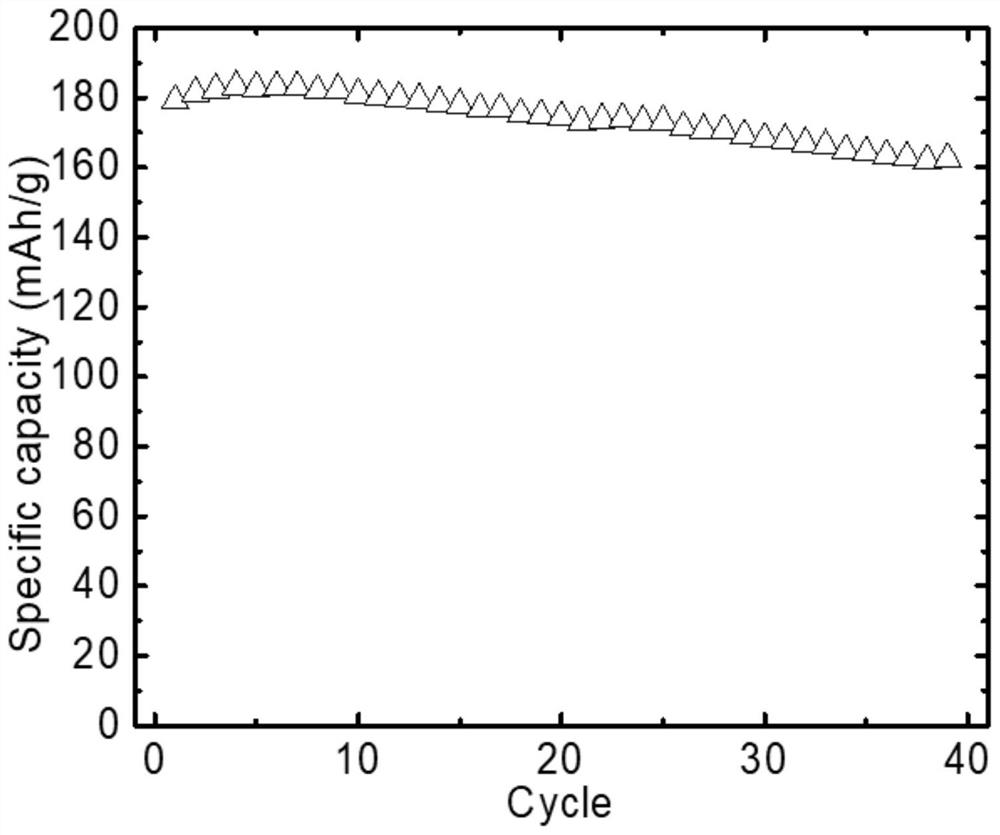

A technology of polyanions and iron compounds, which is applied in the field of cathode materials for batteries, can solve the problems of lithium-ion battery coulombic efficiency and long-term cycle performance to be optimized, and achieve good coulombic efficiency, reduce crystal volume changes, and fast electrochemical reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

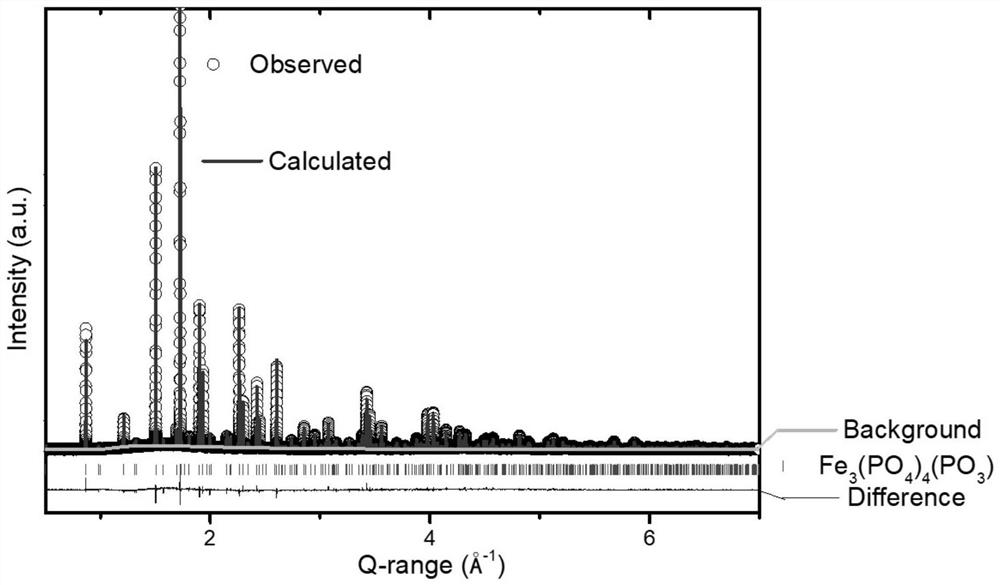

[0035] S1. Synthesis of Fe with three-dimensional porous crystal structure by hydrothermal method 3 (PO 4 ) 4 (PO 3 ) compound: Ferric chloride (Ⅲ) and phosphoric acid at a molar ratio of 1:1 are used as precursors, and the reaction solution is a mixture of water and ethanol at a ratio of 1:0.1 (volume ratio), with a molar concentration of 0.5M, fully After reacting for 15 hours, the three-dimensional porous crystal structure of Fe 3 (PO 4 ) 4 (PO 3 ) compound;

[0036] S2, solid doping: with the Fe that step S1 makes 3 (PO 4 ) 4 (PO 3 ) compound and silicon oxide as precursors, with a molar ratio of 0.8:0.2, ball milling and mixing at 200rpm for 36h, and then sintering at 800°C for 36h with a solid-state method. Silicon-doped Iron-based Polyanion Compound Fe with Electron Diffusion Pathway 3 (P 0.8 Si 0.2 o 4 ) 4 (P 0.8 Si 0.2 o 3 ), x=0.2.

Embodiment 2

[0038] S1. Synthesis of Fe with three-dimensional porous crystal structure by hydrothermal method 3 (PO 4 ) 4 (PO 3 ) Compound: Ferric nitrate (Ⅲ) and ammonium phosphate at a molar ratio of 1:3 are used as precursors, and the reaction solution is a mixture of water and ethanol at a ratio of 1:0.5 (volume ratio), with a molar concentration of 1M, fully reacted at 150°C 20h, the three-dimensional porous crystal structure of Fe 3 (PO 4 ) 4 (PO 3 ) compounds;

[0039] S2, solid doping: with the Fe that step S1 makes 3 (PO 4 ) 4 (PO 3 ) compound and silicon oxide as precursors, the molar ratio is 0.9:0.1, ball milling and mixing at 400rpm for 24h, and then sintering at 1000°C for 12h by solid-state method, the sintering atmosphere is 99.99% ultra-pure oxygen, and the three-dimensional ion Silicon-doped Iron-based Polyanion Compound Fe with Electron Diffusion Pathway 3 (P 0.9 Si 0.1 o 4 ) 4 (P 0.9 Si 0.1 o 3 ), x=0.1.

Embodiment 3

[0041] S1. Synthesis of Fe with three-dimensional porous crystal structure by hydrothermal method 3 (PO 4 ) 4 (PO 3 ) compound: Ferric chloride (Ⅲ) and phosphoric acid at a molar ratio of 3:1 are used as precursors, and the reaction solution is a mixture of water and ethanol at a ratio of 1:0.3 (volume ratio), with a molar concentration of 2M, fully reacted at 200°C 12h, the three-dimensional porous crystal structure of Fe 3 (PO 4 ) 4 (PO 3 ) compound;

[0042] S2, solid doping: with the Fe that step S1 makes 3 (PO 4 ) 4 (PO 3 ) compound and silicon hydroxide as precursors, the molar ratio is 0.95:0.05, ball milling and mixing at 300rpm for 48h, and then sintering at 900°C for 24h by solid-state method, the sintering atmosphere is 99.99% ultra-pure oxygen, and the three-dimensional ion Silicon-doped iron-based polyanion compound Fe with electron diffusion path 3 (P 0.95 Si 0.05 o 4 ) 4 (P 0.95 Si 0.05 o 3 ), x=0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com