Preparation method and application of attapulgite composite adsorbent material

A composite adsorption and attapulgite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of limited adsorption capacity of heavy metals, and achieve the effect of improving adsorption effect, promoting production, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

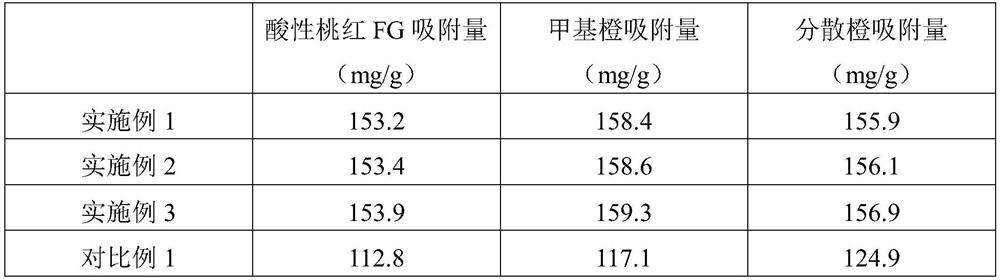

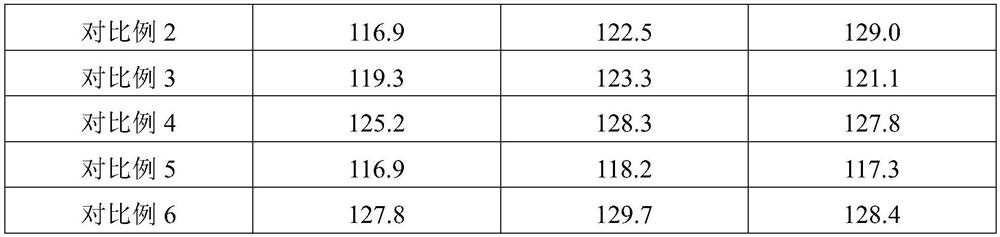

Examples

Embodiment 1

[0034] A kind of preparation method of attapulgite composite adsorbent material, concrete steps are as follows:

[0035](1) Attapulgite is firstly used as raw material, modified by N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain amino-modified attapulgite, and then glutaric anhydride, chlorine Iron oxide is further modified to obtain carboxyl-modified magnetic attapulgite;

[0036] (2) Then use carboxyl-modified magnetic attapulgite, coconut shell powder, surface hydroxylation modified silica gel, and acrylic acid premixed solution as raw materials, and perform a polymerization reaction to obtain a mixed solution;

[0037] (3) Adding Candida utilis and Rhizopus oryzae into the mixed solution, fermenting, filtering, drying, grinding and sieving to obtain the attapulgite composite adsorbent material.

[0038] In step (1), the attapulgite is pretreated first, and the specific method is as follows: first add the attapulgite to water with 4 times the weight, 800W ult...

Embodiment 2

[0053] A kind of preparation method of attapulgite composite adsorbent material, concrete steps are as follows:

[0054] (1) Attapulgite is firstly used as raw material, modified by N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain amino-modified attapulgite, and then glutaric anhydride, chlorine Iron oxide is further modified to obtain carboxyl-modified magnetic attapulgite;

[0055] (2) Then use carboxyl-modified magnetic attapulgite, coconut shell powder, surface hydroxylation modified silica gel, and acrylic acid premixed solution as raw materials, and perform a polymerization reaction to obtain a mixed solution;

[0056] (3) Adding Candida utilis and Rhizopus oryzae into the mixed solution, fermenting, filtering, drying, grinding and sieving to obtain the attapulgite composite adsorbent material.

[0057] In step (1), the attapulgite is firstly pretreated, and the specific method is as follows: first add the attapulgite to water with 6 times the weight, 500W ...

Embodiment 3

[0072] A kind of preparation method of attapulgite composite adsorbent material, concrete steps are as follows:

[0073] (1) Attapulgite is firstly used as raw material, modified by N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane to obtain amino-modified attapulgite, and then glutaric anhydride, chlorine Iron oxide is further modified to obtain carboxyl-modified magnetic attapulgite;

[0074] (2) Then use carboxyl-modified magnetic attapulgite, coconut shell powder, surface hydroxylation modified silica gel, and acrylic acid premixed solution as raw materials, and perform a polymerization reaction to obtain a mixed solution;

[0075] (3) Adding Candida utilis and Rhizopus oryzae into the mixed solution, fermenting, filtering, drying, grinding and sieving to obtain the attapulgite composite adsorbent material.

[0076] In step (1), the attapulgite is first pretreated, and the specific method is as follows: first add the attapulgite to water with 5 times the weight, 700W ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com