Binder, preparation method thereof and application of binder in lithium ion battery

A binder and structural formula technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., to achieve good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

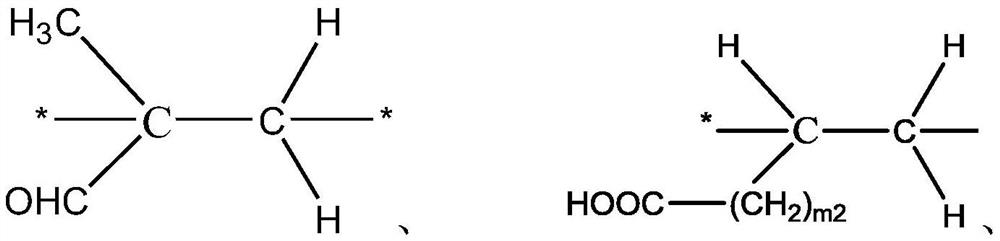

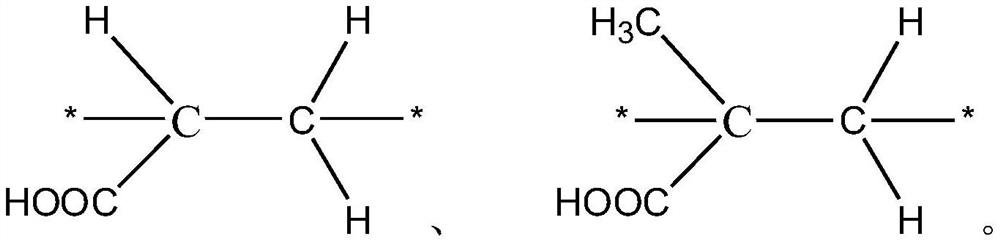

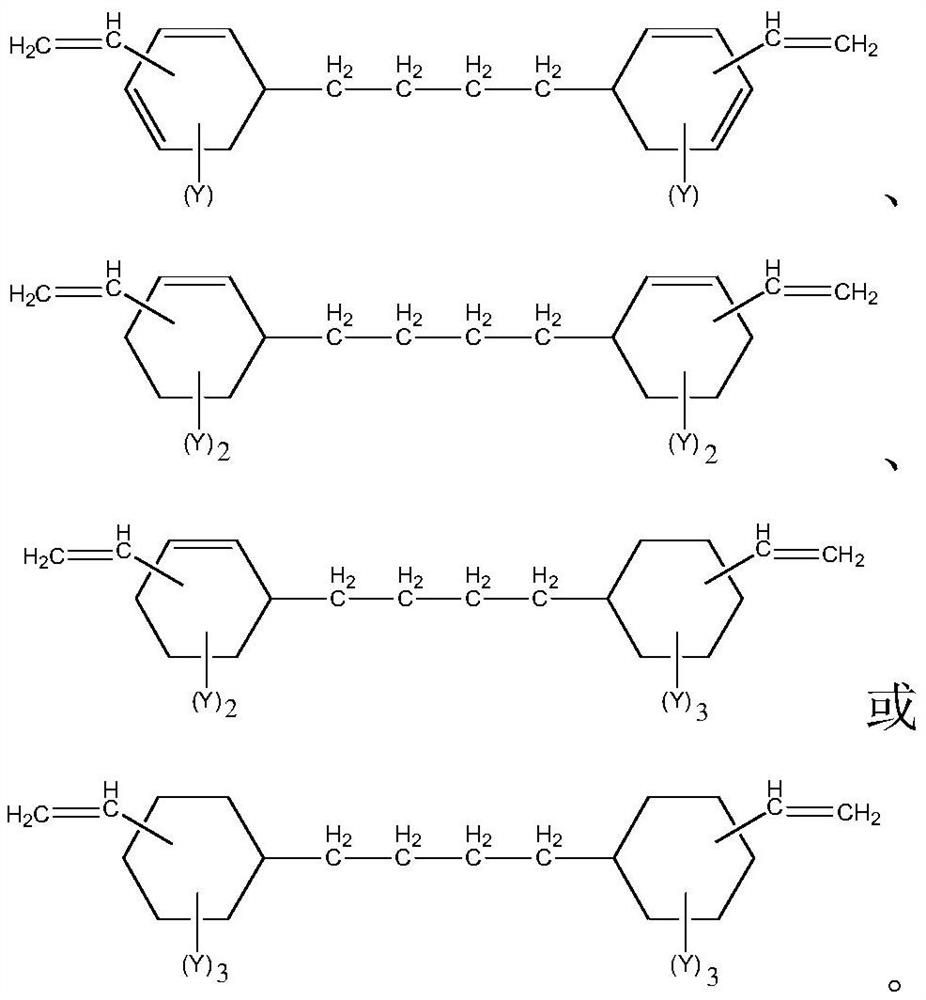

Method used

Image

Examples

Embodiment 1

[0088] (1) Preparation of four-arm star-shaped positive electrode binder

[0089] ①Styrene, butadiene, and methacrylic acid are rinsed with 5% NaOH or deionized water several times to remove the polymerization inhibitor; then the three monomers are distilled to remove water; <5ppm level water residue and impurities are required residual;

[0090] ② Mix sec-butyllithium / DVB / aromatic solvent = 1 / 0.1 / 100 parts by mass, and keep stirring at 60 rpm for 10 minutes at 50°C to obtain an anionic initiator core with an average functionality of 4;

[0091]③ Take 1 part of initiator solution (parts by mass, the same below) and 200 parts of TMF solvent, mix them in the reactor, keep the stirring speed at 60 rpm, and slowly raise the temperature to 50°C to complete the preparation before the reaction;

[0092] ④First add 5 parts of styrene to the reaction system of step ③; add 50 parts of butadiene after 0.5 hours; add 10 parts of methacrylic acid after about 4.5 hours; Shaped polymer, th...

Embodiment 2

[0100] (1) Preparation of eight-armed star-shaped cathode binder

[0101] ①Styrene, butadiene, and methacrylic acid are rinsed with 5% NaOH or deionized water several times to remove the polymerization inhibitor; then the three monomers are distilled to remove water; <5ppm level water residue and impurities are required residual;

[0102] ② Mix sec-butyllithium / DVB / aromatic solvent = 1 / 0.1 / 100 parts, and keep stirring at 110 rpm for 20 minutes at 50°C to obtain an anionic initiator core with an average functionality of 8;

[0103] ③Take 1 part of the initiator solution, dissolve 200 parts of the solvent TMF in the reactor and mix, keep the stirring speed at 60rpm, and slowly raise the temperature to 50°C to complete the preparation before the reaction;

[0104] ④First add 5 parts of styrene to the reaction system of step ③; add 50 parts of butadiene after 0.5 hours; add 10 parts of methacrylic acid after about 4.5 hours; add ethanol after about 10 minutes to complete the reac...

Embodiment 3

[0107] The difference from Example 1 is that the positive electrode main material of the positive electrode sheet prepared in step (2) in this Example 3 is NCM622.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com