Laser cladding device and method based on machine vision and ultrasonic vibration

A technology of laser cladding and ultrasonic vibration, which is applied in the coating process of metal materials, coating, etc., can solve the problems that the vibration angle cannot be adjusted, the size of the molten pool cannot be directly obtained, and the ultrasonic vibration cannot directly affect the laser molten pool. Achieve the effect of reducing energy loss and improving the quality of cladding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

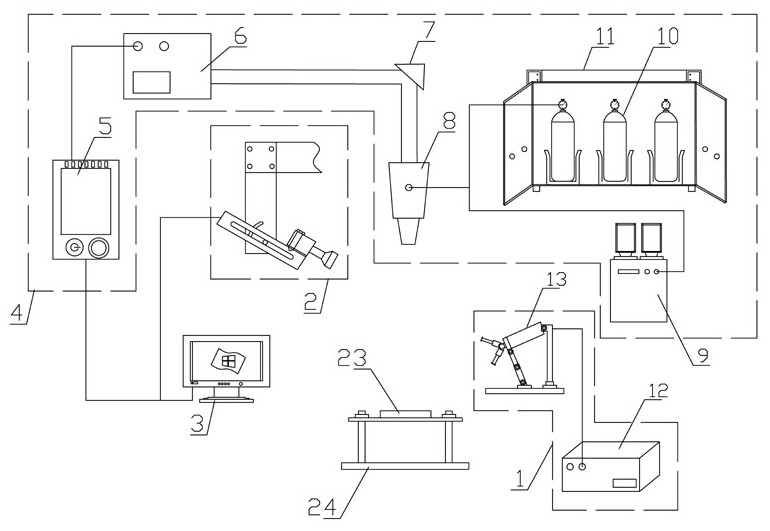

[0046] Embodiment 1: as attached figure 1 As shown, a laser cladding device based on machine vision and ultrasonic vibration is disclosed, including an ultrasonic vibration mechanism 1, an industrial camera mechanism 2, an adjustment and control mechanism 3, and a laser cladding mechanism 4;

[0047] The ultrasonic vibration mechanism 1 is used to apply ultrasonic vibration to the laser molten pool 23;

[0048] The industrial camera mechanism 2 is used to obtain the geometric features of the laser melting pool, wherein the geometric features of the laser melting pool include melting width, melting height and melting depth;

[0049] The adjustment and control mechanism 3 is used to communicate with the laser cladding mechanism 4 and the industrial camera mechanism 2; construct the pose adjustment program during laser cladding; realize laser cladding based on the fuzzy PID control strategy according to the geometrical characteristics of the laser molten pool Adaptive tuning of ...

Embodiment 2

[0055] Embodiment 2: as attached figure 2 As shown, a laser cladding device based on machine vision and ultrasonic vibration is disclosed, wherein the adjustment and control mechanism 3 includes a pose adjustment construction unit, a parameter adaptive tuning unit and a data export unit;

[0056] Pose adjustment construction unit, "discrete and layer" preset complex parts, and build a pose adjustment program for laser cladding;

[0057] Parameter self-adaptive tuning unit, based on the fuzzy PID control strategy, realizes self-adaptive tuning of laser cladding process parameters according to the geometric characteristics of the laser molten pool;

[0058] The data export unit is used to export data to the industrial camera mechanism 2 and the laser cladding mechanism 4, wherein the data includes parameters, programs and control instructions.

[0059] In the above technical solution, the adjustment and control mechanism 3 can be the main control computer, which is equipped wi...

Embodiment 3

[0061] Embodiment 3: as attached figure 1 As shown, a laser cladding device based on machine vision and ultrasonic vibration is disclosed, wherein the laser cladding mechanism 4 includes a laser control board 5, a fiber laser 6, a laser reflector 7, a synchronous powder feeding laser head 8, and a powder feeder 9 and a plurality of protective gas cylinders 10;

[0062] The adjustment and control mechanism 3 is connected to the laser control board 5, and the laser control board 5, the fiber laser 6, the laser reflector 7, and the synchronous powder feeding laser head 8 are connected in sequence; the laser control board 5 receives the data sent by the adjustment and control mechanism 3, and controls the The laser emitter emits laser light, and the laser light is emitted by the synchronous powder feeding laser head 8 through the laser reflector 7 . Among them, the laser control board 5 acts as a bridge, receiving data such as parameters, programs and control instructions sent by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com