Process treatment method and system for oil-water separation and desalination of garbage

A technology of oil-water separation and treatment method, which is applied in the field of oil-water separation and desalination process treatment method and its system, which can solve the problems of large floor area, low treatment efficiency and high treatment difficulty, and achieve good deodorization effect and high-efficiency treatment Promoted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

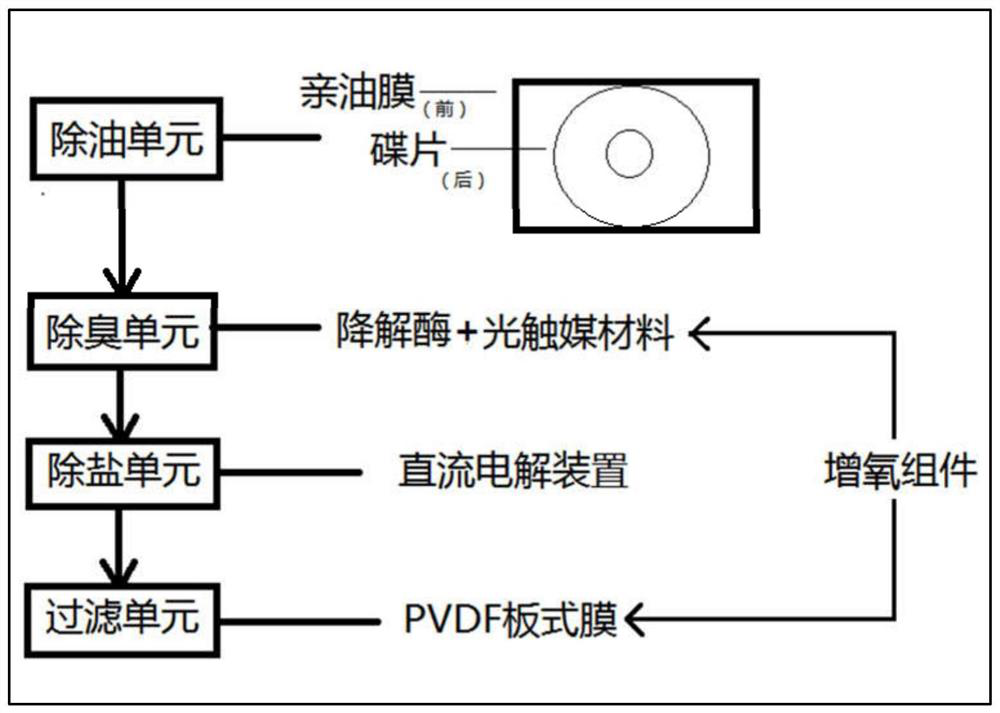

[0029] A process treatment method and system for oily water treatment and desalination of garbage:

[0030] 1) Degreasing unit: For components including the lipophilic film and the disc, the lipophilic film and the disc are stacked one after the other (such as figure 1 As shown in the combination of lipophilic film and disc), the oil and water first pass through the lipophilic film to absorb the oil, and the adsorbed oil is removed by rotating the disc through the rotating machine to degrease the garbage;

[0031] The lipophilic membrane is made of electrospun nanofiber membrane, epoxy-modified silicone resin, acrylate and hydrophobic hydroxyethyl cellulose, the proportions are respectively 2:6:5:3, and the organic solvent DMF is used for dissolution. Thoroughly stir evenly and dry to form a film;

[0032] The porosity of the obtained lipophilic membrane is 70-80%;

[0033] 2) Deodorization unit: including degradative enzyme tank and photocatalyst material to degrade the bio...

Embodiment 2

[0039] A process treatment method for oily water treatment and desalination of garbage

[0040] Take 5kg of crushed municipal solid waste for the following treatment:

[0041] 1) Oil removal treatment: For the components including the lipophilic film and the disc, the lipophilic film and the disc are stacked in the form of one after the other, the oil and water first pass through the lipophilic film to absorb the oil, and the rotating disc removes the adsorbed oil Carry out degreasing treatment of garbage;

[0042] The lipophilic membrane is made of electrospun nanofiber membrane, epoxy-modified silicone resin, acrylate and hydrophobic hydroxyethyl cellulose, the proportions are respectively 4:8:2:2, and the organic solvent DMF is used for dissolution. Thoroughly stir evenly and dry to form a film;

[0043] The porosity of the obtained lipophilic membrane is 70-80%;

[0044] 2) Deodorization treatment: use degradative enzymes and photocatalyst materials to degrade and catal...

Embodiment 3

[0049] A process treatment method for oily water treatment and desalination of garbage

[0050] Take 5kg of crushed municipal solid waste for the following treatment:

[0051] 1) Oil removal treatment: For the components including the lipophilic film and the disc, the lipophilic film and the disc are stacked in the form of one after the other, the oil and water first pass through the lipophilic film to absorb the oil, and the rotating disc removes the adsorbed oil Carry out degreasing treatment of garbage;

[0052] The lipophilic membrane is made of electrospun nanofiber membrane, epoxy-modified silicone resin, acrylate and hydrophobic hydroxyethyl cellulose, the proportions are respectively 3:5:5:4, and the organic solvent DMF is used for dissolution. Thoroughly stir evenly and dry to form a film;

[0053] The porosity of the obtained lipophilic membrane is 70-80%;

[0054] 2) Deodorization treatment: use degradative enzymes and photocatalyst materials to degrade and catalyz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com