Straw board for vegetation slope protection and production method thereof

A production method and technology for straw boards, which are applied in the field of straw boards, can solve the problems of long construction period, high cost, waste of biomass resources, etc., and achieve the effects of good environmental protection and good ecological benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a specific preparation example, the crushed straw is soaked for 24-72 hours and grinded, and then enters the drying process; by soaking the crushed straw in clear water, the cellulose in the straw fiber can be mixed with water The molecules are fully infiltrated, and depending on the air and the microorganisms carried by the straw itself, the natural fiber dissociation treatment can be performed on the straw at room temperature and in a humid environment, thereby removing a small amount of hemicellulose that affects the mechanical strength of the biomass sheet. , and will dissolve a small amount of lignin, which will greatly reduce the strength and life of the board, and can also soften the intercellular layer of the straw cells. The soaked straw fragments are mechanically grinded by friction and tearing through the mechanical rotation friction of the grinder, so that the soft fibers can be better separated and the active hydroxyl groups at the end of the cellulose ar...

preparation example 1

[0044] 1) Crushing the corn stalks, wherein the corn stalks are the current year's stalks. The crushed straw is screened, and the straw fragments between 6-25 mesh screens are selected; the alkalized straw pulp is transported by a screw conveyor to an air-flow agitation dryer for drying. The straw fragments were dried in an airflow agitation dryer to make the water content reach 16%; and then the dried straw fragments were subjected to ultrasonic treatment, the ultrasonic power was 100kW, the ultrasonic frequency was 30kHz, and the ultrasonic time was 30min.

[0045] 2) The dried straws were assembled, steamed and hot-pressed, wherein the pressure was 2 MPa, the hot-pressing temperature was 180° C., and the hot-pressing time was 280 seconds to form a 9 cm straw board.

[0046] The performance test of the straw board 1 shows that the density of the straw board is 0.6g / cm 3 , Shore hardness is 61A; water content is 10.4%.

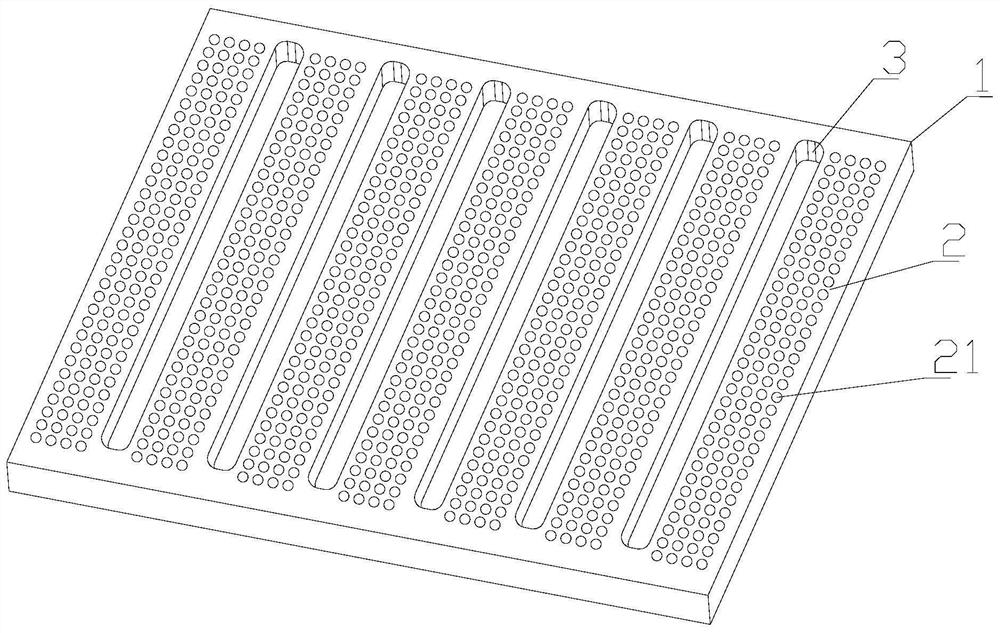

[0047] The straw board 1 is perforated according to t...

preparation example 2

[0049] 1) Crush the sorghum stalks, sieve the crushed stalks, and select straw fragments between 6-25 mesh screens; the crushed straws must be soaked for 72 hours and grinded; after the grinded The straw pulp is transported to the airflow agitation dryer by the screw conveyor for drying. Dry the straw fragments in an airflow agitation dryer to make the moisture content reach 16%.

[0050] 2) The dried straws are assembled, steamed and hot-pressed, wherein the pressure is 2 MPa, the hot-pressing temperature is 160° C., and the hot-pressing time is 360 seconds to form a 5 cm straw board.

[0051] The performance test of the second straw board shows that the density of the straw board is 0.78g / cm 3 , Shore hardness is 52A; moisture content is 15.5%.

[0052] The second straw board is punched according to the standard that the diameter of the through hole is 30 cm and the hole spacing is 20 cm to form the second straw board with through holes.

[0053] A groove is arranged betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com