Porous lithium titanate material and preparation method thereof, negative electrode material and lithium ion battery

A technology of porous lithium titanate and negative electrode materials, applied in the direction of negative electrodes, titanates, secondary batteries, etc., can solve the problems of poor low temperature resistance, achieve low cost, improve low temperature resistance, and increase specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

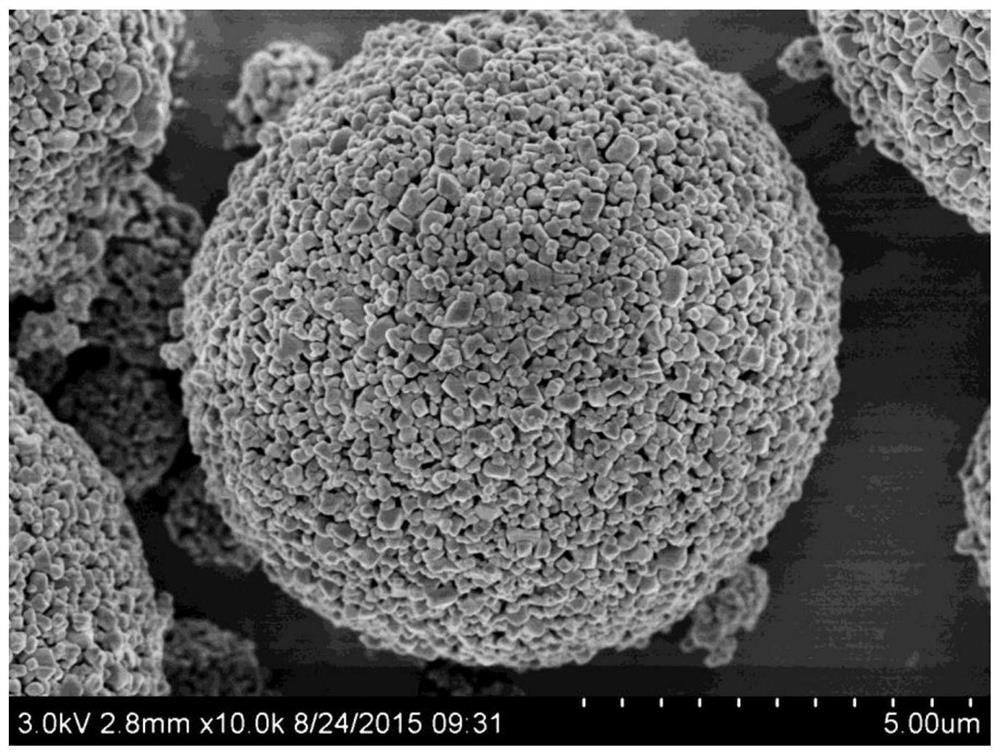

[0022] In a typical implementation of the present application, a method for preparing a porous lithium titanate material is provided. The preparation method includes: step S1, homogenizing the mixed solution including titanium source, lithium source and dispersant in sequence , the first drying and the first calcination to obtain the primary product of lithium titanate; step S2, performing pelletizing treatment on the primary product of lithium titanate to obtain microspheres; and step S3, performing the second calcination on the microspheres to obtain porous titanate lithium material.

[0023] The longer the diffusion path of lithium ions in the lithium titanate material, the larger the concentration polarization and the worse the low temperature performance. This application redesigns the structure of the primary product of lithium titanate to obtain microspheres with a certain skeleton structure, and then performs a second calcination treatment on the microspheres, so that ...

Embodiment 1

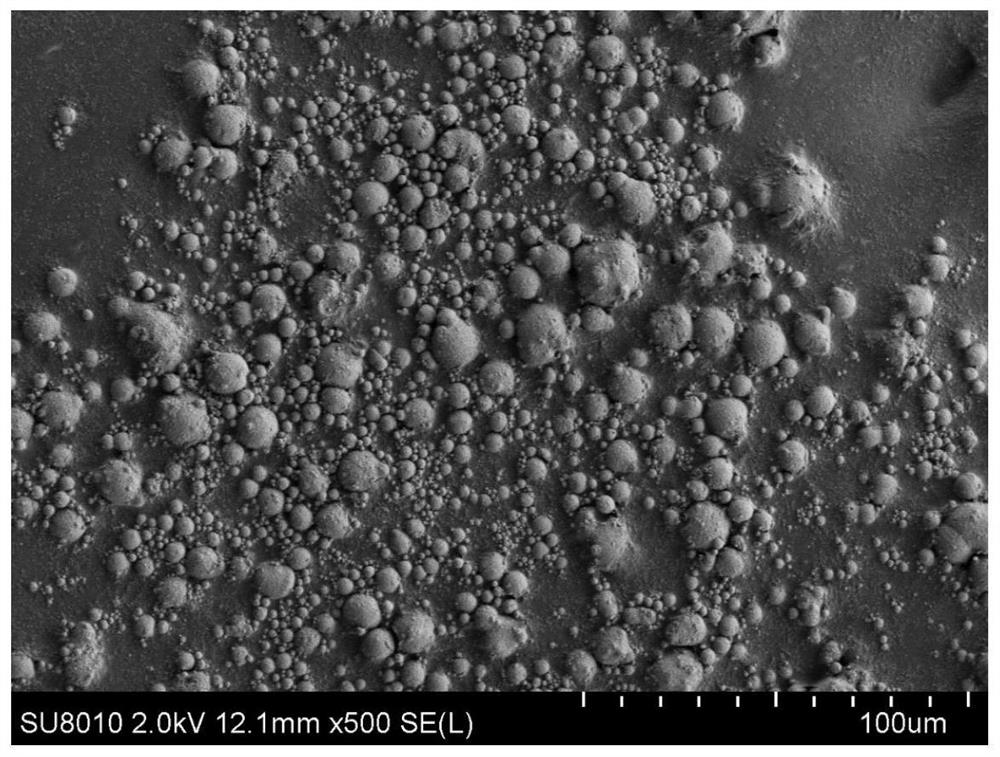

[0041] Mix titanium in titanium dioxide and lithium in lithium carbonate with water at a molar ratio of 1:0.81 to obtain a mixed solution, which is sequentially ball milled, spray-dried, and first calcined to obtain the primary product of lithium titanate. Among them, the rotation speed of the ball mill is 3500rpm / min, the temperature of spray drying is 250°C, the temperature of the first calcination is 750°C, the heating rate of the first calcination is 10°C / min, and the first calcination is calcined after reaching the temperature of 750°C 4h, wherein the SEM image of the powder obtained after spray drying is as follows figure 1 shown.

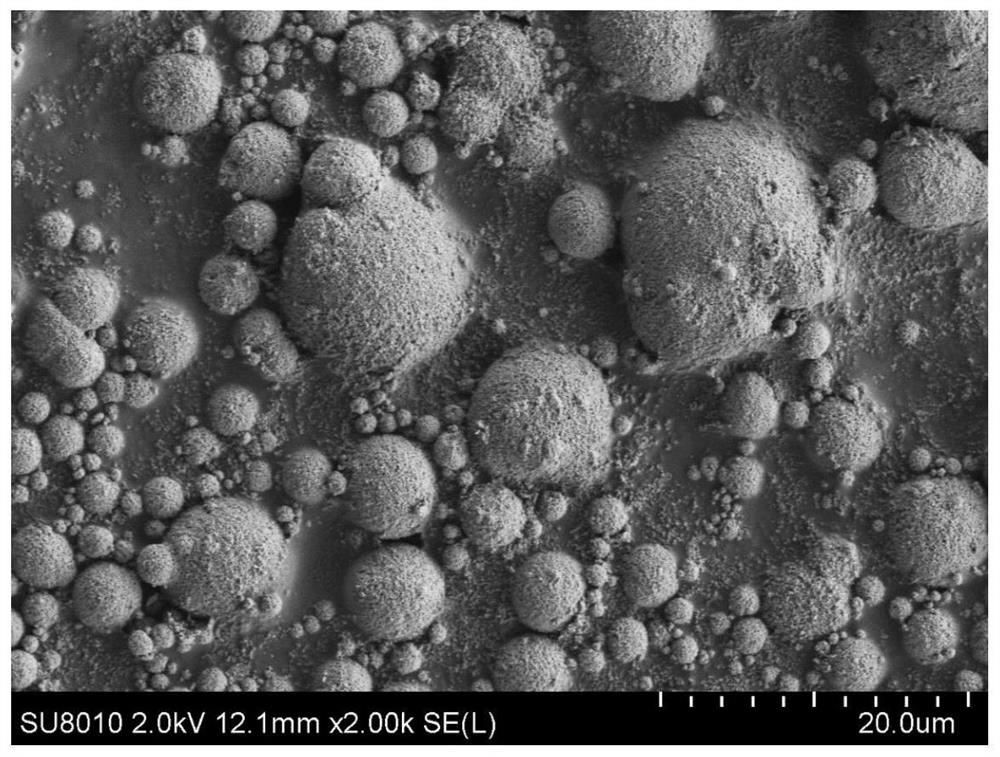

[0042] Use zirconia beads as the grinding medium to carry out wet grinding treatment on the mixture of lithium titanate primary product and water to obtain a slurry of nano-sized particles with a particle size D90 of 560nm; The slurry is sprayed into pellets to obtain microspheres, and the SEM image of the microspheres is as follows figure...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that the molar ratio of titanium in titanium dioxide to lithium in lithium carbonate is 1:0.88 to obtain microspheres and finally obtain a porous lithium titanate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com