Water-containing manganese carbonate slag-based liquid cementing material and preparation method and application thereof

A technology based on manganese carbonate slag and manganese carbonate slag is applied in the field of building cementitious materials, which can solve the problems of long operation process, high cost and long process line, and achieve the effects of short operation process, low cost and quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

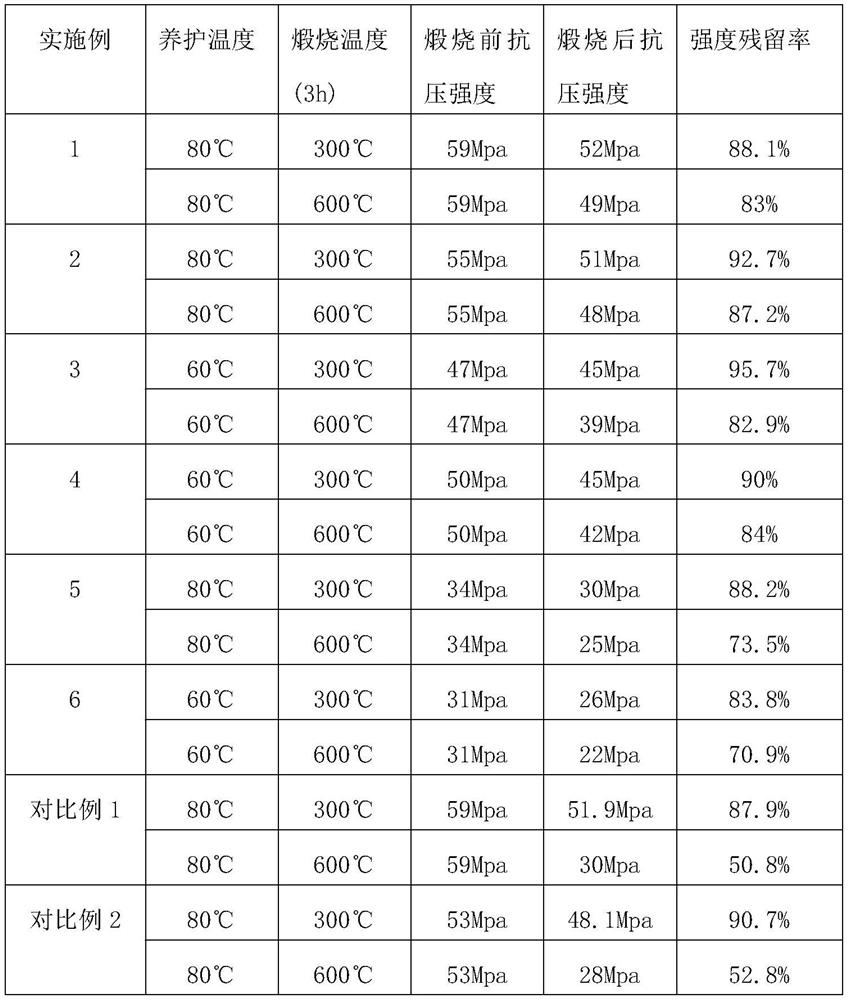

Examples

Embodiment 1

[0024]Example 1 is used to illustrate preferred embodiments of the invention.

[0025]80 parts by mass of aqueous carbonate slag, 300 parts by mass zirconia abrasive body, 112 parts by mass of phosphoric acid, 32 parts by mass of water, 8 parts by mass of titanium slag, 8 parts by mass of iron ore powder and 2 parts by mass of abrasive The mixing ball mill is sealed, grinded, and the zirconia grinding body is removed, and the medium having a median particle size of 2.68 μm is obtained to obtain a hydrazine-containing manganese carbonate residue liquid heat-resistant gelation material. It is solids 67%, stirred rapidly for 2 minutes, and the test block and test performance are made according to GB / T50081-2016 "Ordinary Concrete Properties Performance Experimental Method".

[0026]The zirconium oxide grinding body placed in the grinding tank is: 0.8 mm zirconia grinding body, 1.4 mm zirconia grinding body and 2.5 mm zirconia grinding body mass ratio of 1: 1: 4.

Embodiment 2

[0028]Embodiment 2 is used to illustrate preferred embodiments of the invention.

[0029]100 parts by mass of the aqueous carbonate slag, 300 parts by mass zirconia abrasive body, 112 parts by mass of phosphoric acid, 40 parts by mass of water, 10 parts by mass of titanium slag, 10 parts by mass of iron ore powder and 3 parts by mass of abrasive The mixing ball mill is sealed, ground, remove the zirconia grinding body to obtain a slurry of 2.88 μm in the medium value of 2.88 μm, to obtain aqueous carbonate slag liquid heat-resistant ceiling material, solids 68%, stirred rapidly for 2min, according to according to according to according to according to according to "Ordinary Concrete Mechanics Performance Experimental Method Standard" production test blocks and test performance.

[0030]The zirconium oxide grinding body placed in the grinding tank is: 0.8 mm zirconia grinding body, 1.4 mm zirconia grinding body and 2.5 mm zirconia grinding body mass ratio of 1: 1: 4.

Embodiment 3

[0032]Embodiment 3 is used to illustrate preferred embodiments of the invention.

[0033]80 parts by mass of the aqueous carbonate slag, 300 parts by mass zirconia abrasive body, 112 parts by mass of phosphoric acid, 32 parts by mass of water, 8 parts by mass of titanium slag, add 8 parts by mass of iron ore powder and 2 parts by mass of grinding The agent is placed in a stirring ball mill, ground, remove the zirconia grinding body to obtain a slurry having a median particle size of 2.68 μm to obtain a water-resistant manganese carbonate residue liquid heat-resistant gelation material. It is solids 69%, stirred rapidly for 2min, and produces test blocks and test performance according to GB / T50081-2016 "Ordinary Concrete Mechanical Performance Experimental Method".

[0034]The zirconium oxide grinding body placed in the grinding tank is: 0.8 mm zirconia grinding body, 1.4 mm zirconia grinding body and 2.5 mm zirconia grinding body mass ratio of 1: 1: 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com