MOFs-based precursor for cobalt-free lithium battery, and preparation method thereof, and positive electrode material and preparation method thereof

A cathode material and precursor technology, applied in the field of lithium battery cathode materials, can solve the problems of Li/Ni mixing, potential safety hazards, and expensive Co, and achieve the effects of reducing sintering temperature, improving rate performance, and improving development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

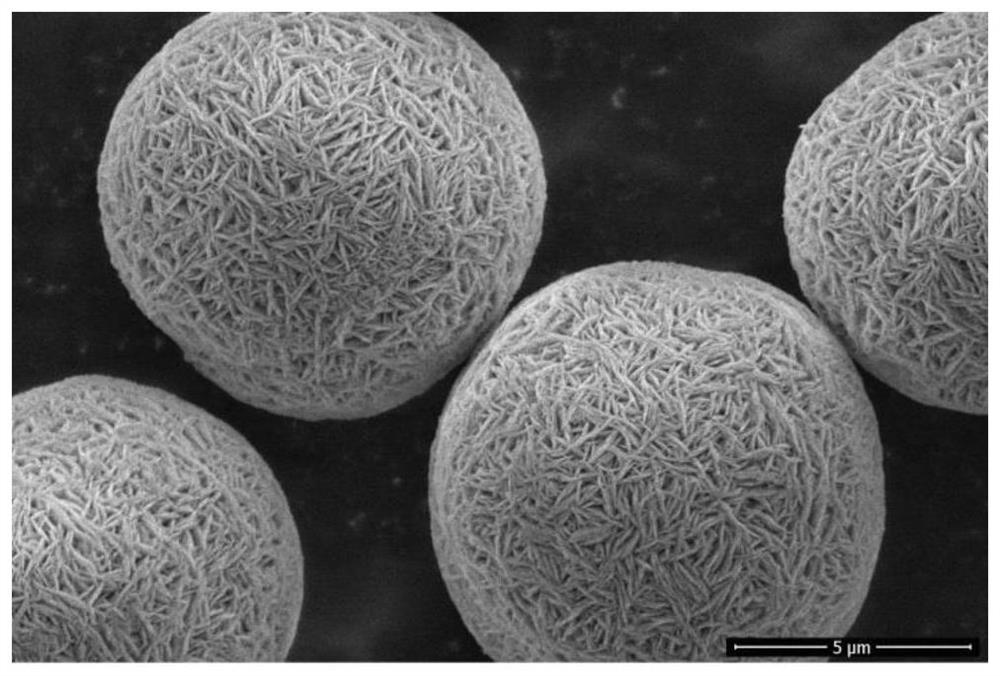

Embodiment 1

[0033] Step 1, at 1m 3 Add the pure water of 500L in the reaction still, 3kg concentration is the liquid caustic soda solution that 1mol / L of 1mol / L and 6kg concentration are 2mol / L, and the volume ratio of toluene carboxylic acid solution and liquid caustic soda solution is 4:1, The pH of the test bottom solution is 11.4-11.6, and N is passed into the reaction kettle 2 , the flow rate is 0.6m 3 / h, the metal molar ratio is 70:30, metal concentration is the nickel-manganese mixed sulfate solution of 2mol / L with metering pump and joins in the reactor with the flow rate of 30L / h, simultaneously adds 1mol / L in the reactor The sodium hydroxide of phenylcarboxylic acid solution and 2mol / L, the flow rate is respectively 5L / h and 10L / h, the pH of the flow adjustment system is maintained between 11.2-11.6 by controlling the flow rate of ammoniacal liquor and sodium hydroxide in the reaction process, stirs The stirring rate of the paddle is 300-400r / min, the reaction temperature of th...

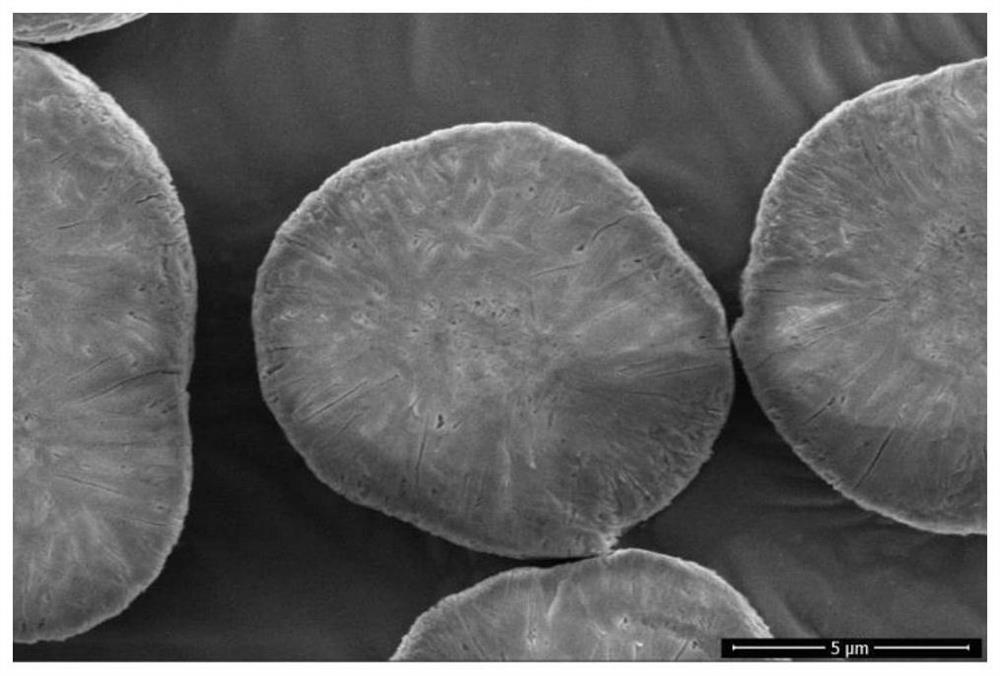

Embodiment 2

[0037] Step 1, at 1m 3 500L of pure water, 3kg concentration of 1.5mol / L 1,2,3,4-butane tetracarboxylic acid solution and 6kg concentration of 3mol / L liquid caustic soda solution were added in the reaction kettle, and the pH of the test bottom liquid was 10.4-11, and feed N into the reactor 2 , the flow rate is 2m 3 / h, the metal molar ratio is 50:50, the nickel-manganese mixed salt solution that metal concentration is 3mol / L joins in the reaction kettle with the flow rate of 40L / h with metering pump, adds 1.5mol / L in the reaction kettle simultaneously 1,2,3,4-butane tetracarboxylic acid solution and 3mol / L sodium hydroxide, the flow rates are 6L / h and 12L / h respectively, and the pH of the system is adjusted by controlling the flow rates of ammonia water and sodium hydroxide during the reaction Maintain between 10-10.6, the stirring speed of the stirring paddle is 150-200r / min, the reaction temperature of the system is 50°C, and the reaction time is 40h. During the reaction...

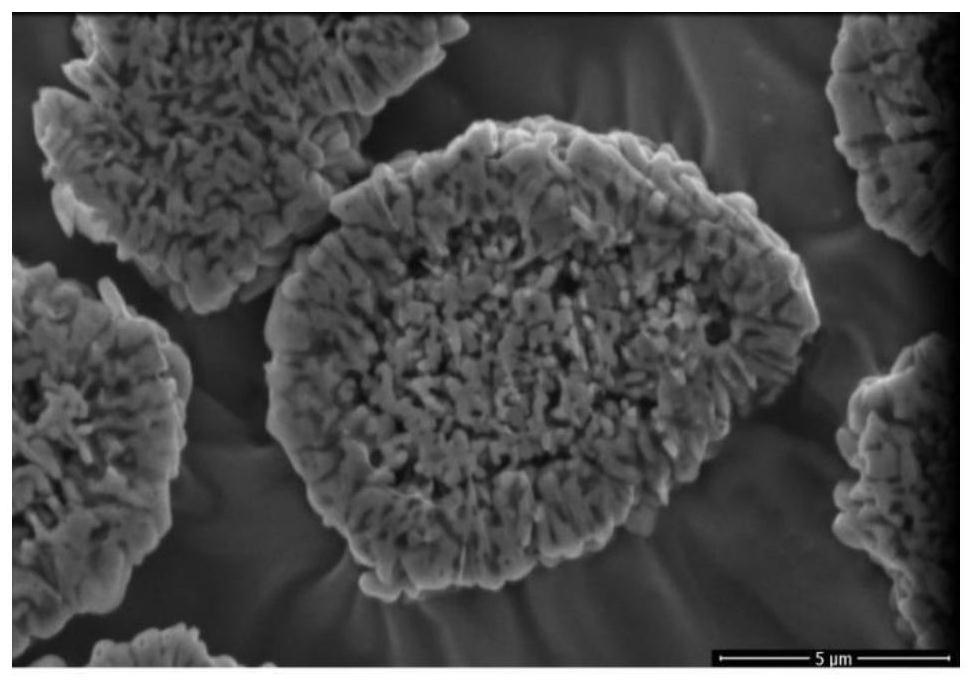

Embodiment 3

[0041] Step 1, at 1m 3 Add 500L of pure water, 3kg concentration of 2mol / L 5-hydroxyisophthalic acid solution and 6kg concentration of 4mol / L liquid caustic soda solution in the reaction kettle, test the pH of the bottom liquid to be 11.7-12, and to react N into the kettle 2 , the metal molar ratio is 25:75, and the nickel-manganese mixed salt solution with metal concentration of 4mol / L is added to the reactor with a flow rate of 50L / h by a metering pump, and 2mol / L of 5-hydroxyl is added to the reactor at the same time The sodium hydroxide of isophthalic acid solution and 4mol / L, flow rate is respectively 7.5L / h and 15L / h, by controlling the pH of the flow adjustment system of ammoniacal liquor and sodium hydroxide in the reaction process between 11.7-12, The stirring rate of the stirring paddle is 300-400r / min, and the reaction temperature of the system is 60°C for 80h. During the reaction, use a laser particle size analyzer to detect the particle size of the particles in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com