Flux material composition and preparation method of flux

A technology of material composition and flux, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve problems such as general effect of flux, general anti-oxidation performance of solder, general anti-oxidation effect, etc., to achieve Improve the performance of flux, reduce the melting point of flux, and increase the effect of dissolving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

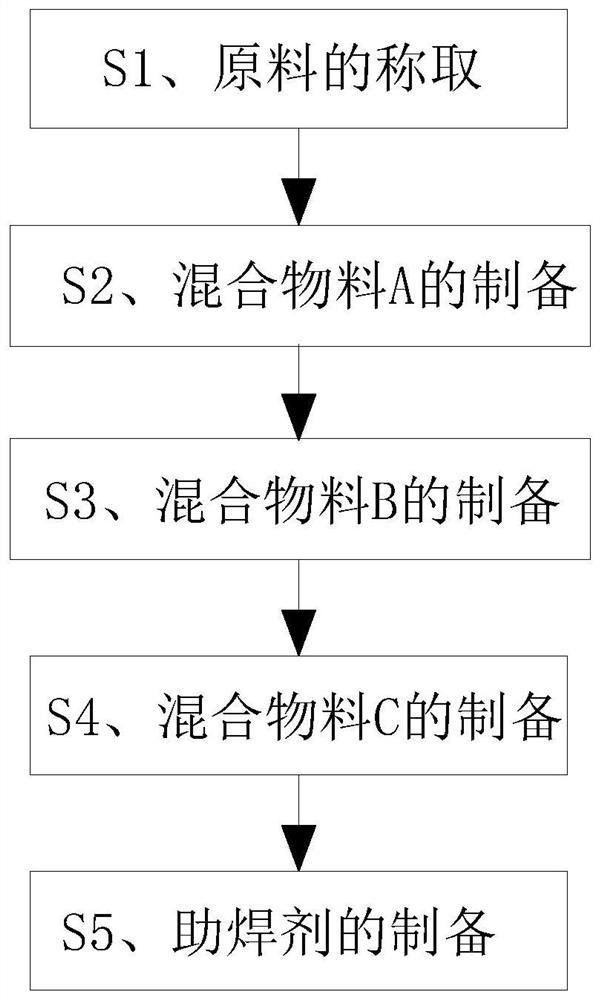

[0023] Example 1: Please refer to figure 1 , the invention discloses a preparation method of a flux material composition and a flux, comprising the following steps:

[0024] S1. Weighing of raw materials: 30 parts of water-based acrylic resin, 10 parts of triethanolamine, 20 parts of melamine formaldehyde resin, 0.5 parts of film forming agent, 5.5 parts of solvent, 5 parts of active agent, 0.3 parts of corrosion inhibitor, 5 parts of lithium chloride , 6 parts of zinc dichloride and 3 parts of dispersant.

[0025] S2. Preparation of mixed material A: put the triethanolamine, solvent and zinc dichloride in step S1 into a container, heat and stir until fusion, the heating temperature is 50°C, and the stirring speed is 300r / min. Time is 25min, obtains required mixed material A, and solvent is methanol, for subsequent use;

[0026] S3. Preparation of mixed material B: Add water-based acrylic resin and melamine formaldehyde resin weighed according to the mass fraction in step S1...

Embodiment 2

[0029] Example 2: Please refer to figure 1 , the invention discloses a preparation method of a flux material composition and a flux, comprising the following steps:

[0030] S1. Weighing of raw materials: 32 parts of water-based acrylic resin, 15 parts of triethanolamine, 28 parts of melamine formaldehyde resin, 1.2 parts of film forming agent, 8 parts of solvent, 6 parts of active agent, 0.4 part of corrosion inhibitor, 5.5 parts of lithium chloride , 8 parts of zinc dichloride and 4 parts of dispersant.

[0031] S2. Preparation of mixed material A: put the triethanolamine, solvent and zinc dichloride in step S1 into a container, heat and stir until fusion, the heating temperature is 52°C, and the stirring speed is 350r / min. The time is 20min, obtains required mixed material A, and solvent is the mixture of ethyl acetate, Virahol, glycol and propylene glycol, for subsequent use;

[0032] S3. Preparation of mixed material B: Add water-based acrylic resin and melamine formald...

Embodiment 3

[0035] Example 3: Please refer to figure 1 , the invention discloses a preparation method of a flux material composition and a flux, comprising the following steps:

[0036] S1. Weighing of raw materials: 35 parts of water-based acrylic resin, 20 parts of triethanolamine, 30 parts of melamine formaldehyde resin, 1.5 parts of film forming agent, 10 parts of solvent, 7 parts of active agent, 0.5 parts of corrosion inhibitor, 6 parts of lithium chloride , 8 parts of zinc dichloride and 5 parts of dispersant.

[0037] S2. Preparation of mixed material A: put the triethanolamine, solvent and zinc dichloride in step S1 into a container, heat and stir until fusion, the heating temperature is 55°C, and the stirring speed is 300 / min. The time is 25min, the required mixture material A is obtained, the solvent is glycol, and it is set aside;

[0038] S3. Preparation of mixed material B: Add water-based acrylic resin and melamine formaldehyde resin weighed according to the mass fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com