Method for preparing graphene on large scale and application

A large-scale preparation and graphene technology, applied in the field of graphene, can solve the problems of waste, hindering the widespread application and commercialization of graphene, and achieve the effect of no pollution, simple and safe process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing graphene from waste paper. In this method, the commercially available A4 paper is first cut into a size of 30mm×20mm, and about 0.8g of paper is weighed, placed in a ceramic ark, and then calcined in a muffle furnace, and the temperature is raised from room temperature to 900°C in 120 minutes. , before the temperature rises to 200°C, high-purity nitrogen is maintained through the quartz tube. Maintain at 900 °C for 10 min, then turn off the power of the tube furnace and cool to room temperature. After the sample was taken out, it was ultrasonically treated in 50mL of 2mol / L HCl solution for 4h. Then, the suspension obtained by sonication was washed with deionized water and 95% ethanol by suction filtration several times. The obtained product was dried in an oven at 100° C. for more than 2 hours to obtain graphene.

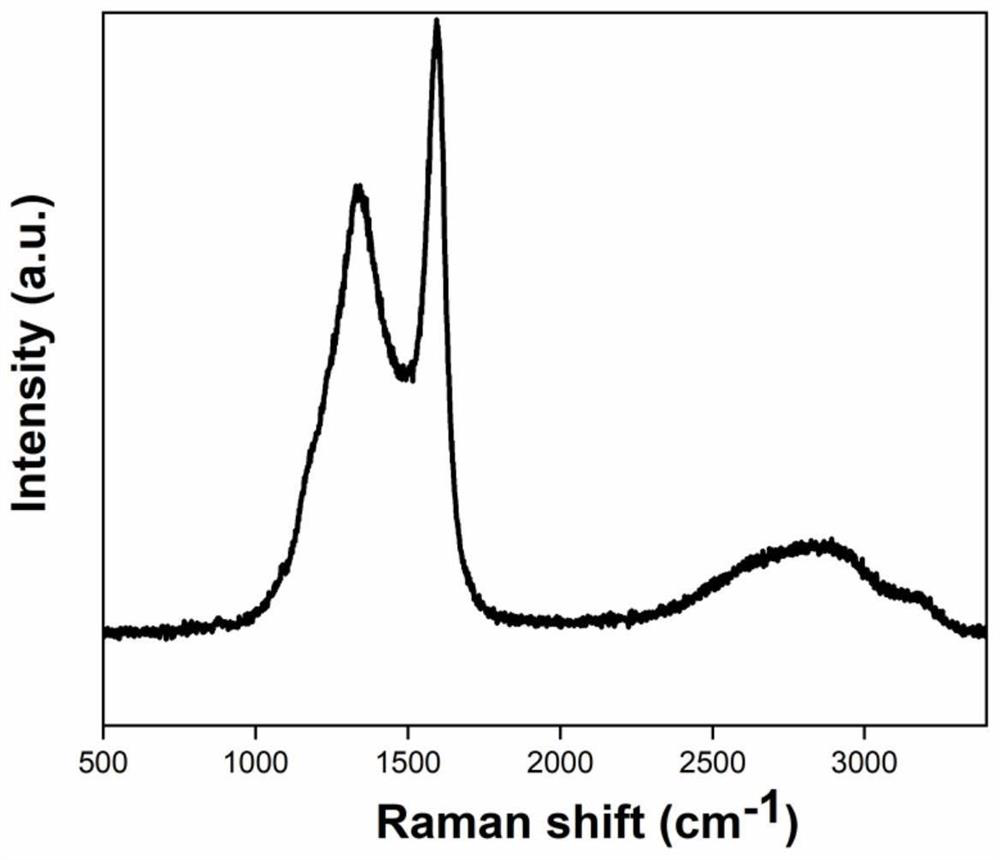

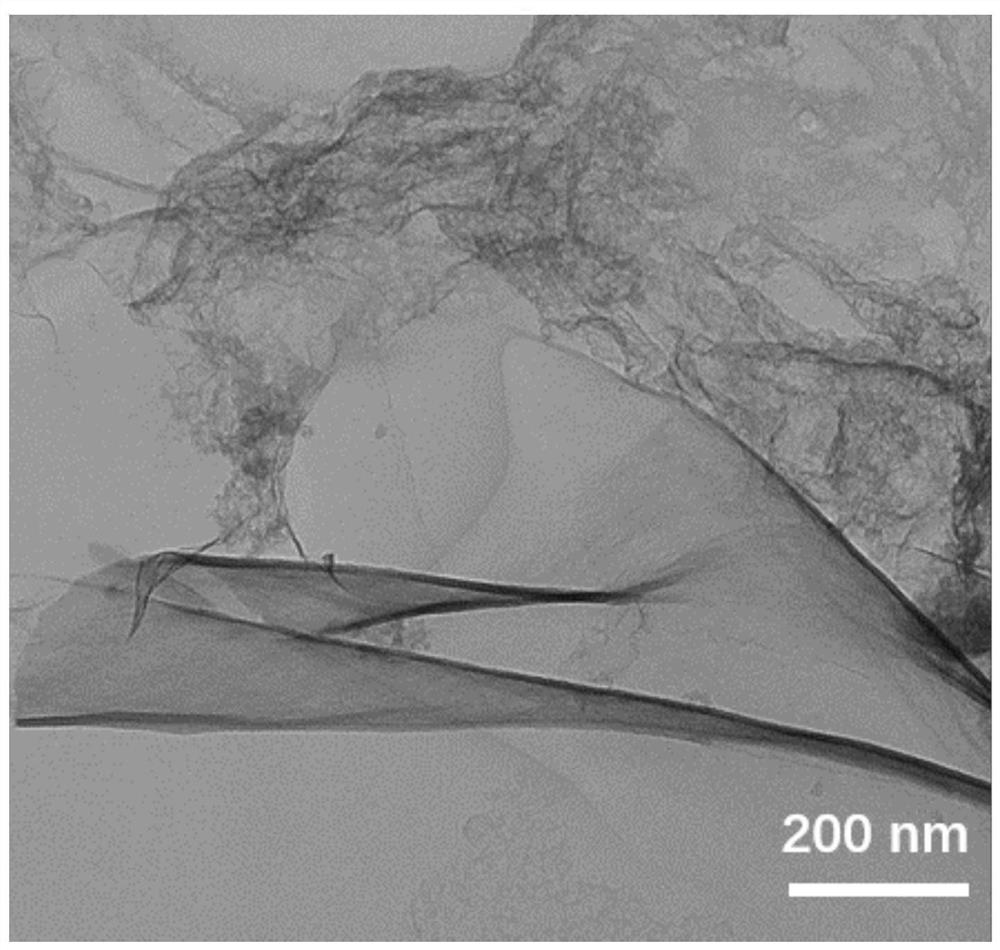

[0043] see figure 1 and figure 2 , figure 1 The Raman spectrum of the graphene prepared for Example 1...

Embodiment 2

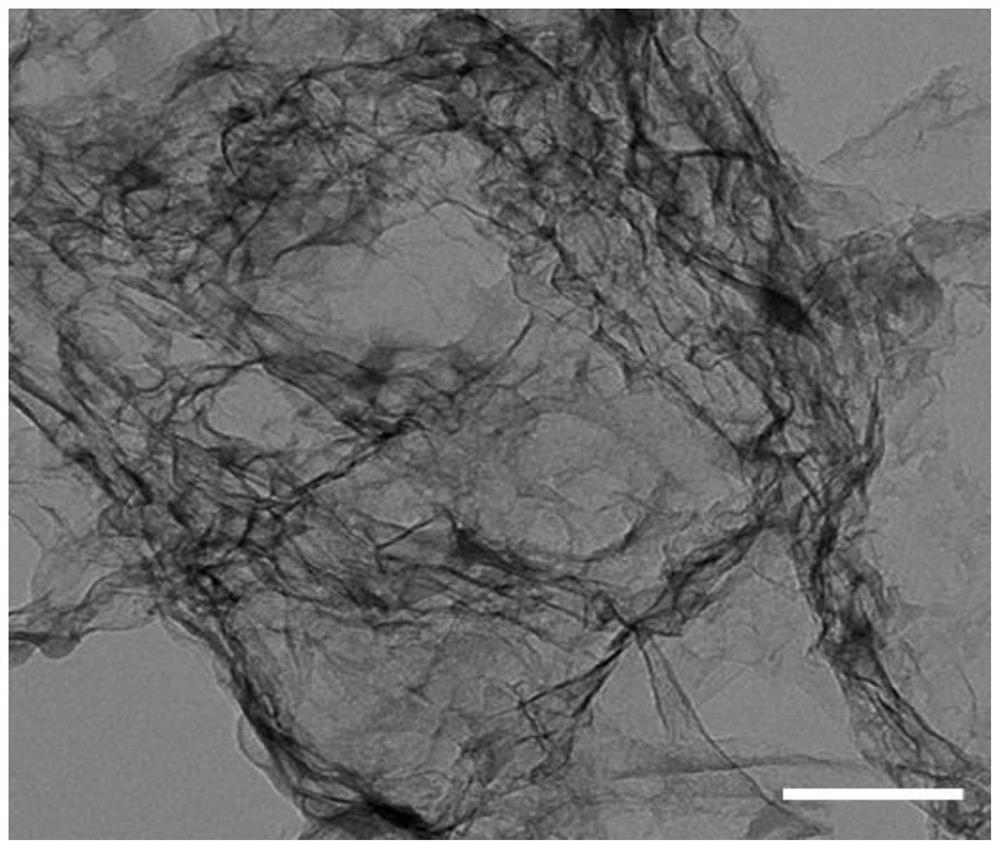

[0047] This embodiment provides a method for preparing graphene from waste paper. In this method, the commercially available A4 paper is first cut into a size of 30mm×20mm, and about 0.8g of paper is weighed, placed in a ceramic ark, and then calcined in a muffle furnace, and the temperature is raised from room temperature to 800°C in 105 minutes. , before the temperature rises to 200°C, high-purity nitrogen is maintained through the quartz tube. Maintain at 800 °C for 10 min, then turn off the power of the tube furnace and cool to room temperature. After the sample was taken out, it was ultrasonically treated in 50mL of 2mol / L HCl solution for 4h. Then, the suspension obtained by sonication was washed with deionized water and 95% ethanol by suction filtration several times. The obtained product was dried in an oven at 100° C. for more than 2 hours to obtain graphene. see image 3 , image 3 It is the transmission electron microscope image of the graphene prepared in Exam...

Embodiment 3

[0050] This embodiment provides a method for preparing graphene from waste paper. In this method, the commercially available A4 paper is first cut into a size of 30mm×20mm, and about 0.8g of paper is weighed, placed in a ceramic ark, and then calcined in a muffle furnace, and the temperature is raised from room temperature to 700°C for 90 minutes. , before the temperature rises to 200°C, high-purity nitrogen is maintained through the quartz tube. Maintain at 700 °C for 10 min, then turn off the power of the tube furnace and cool to room temperature. After the sample was taken out, it was ultrasonically treated in 50mL of 2mol / L HCl solution for 4h. Then, the suspension obtained by sonication was washed with deionized water and 95% ethanol by suction filtration several times. The obtained product was dried in an oven at 100° C. for more than 2 hours to obtain graphene. see Figure 4 , Figure 4 It is a transmission electron microscope image of the graphene prepared in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com