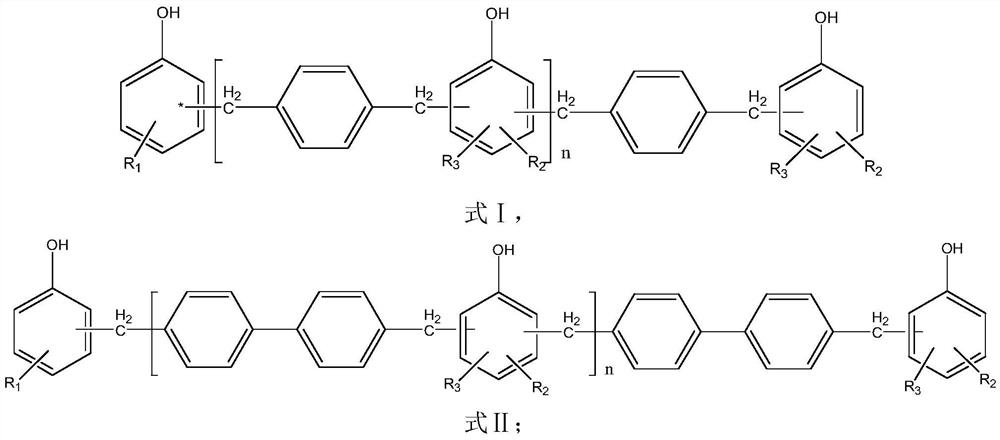

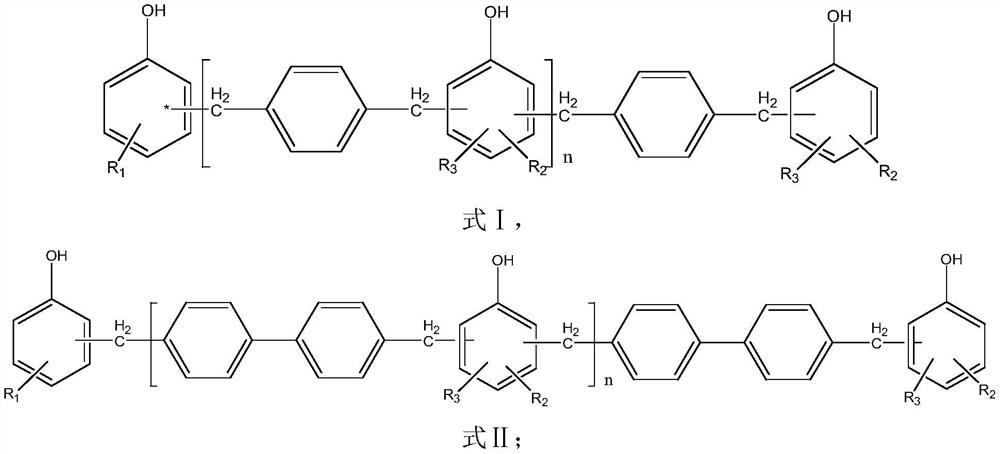

Synthesis method and application of aralkyl phenol resin

A technology of alkylphenol resin and aralkylphenol, which is applied in the field of organic synthesis, can solve problems such as pollution, reduce the heat resistance of the composite system, and compatibility issues, and achieve the goals of reducing pollution, improving toughness, and increasing heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

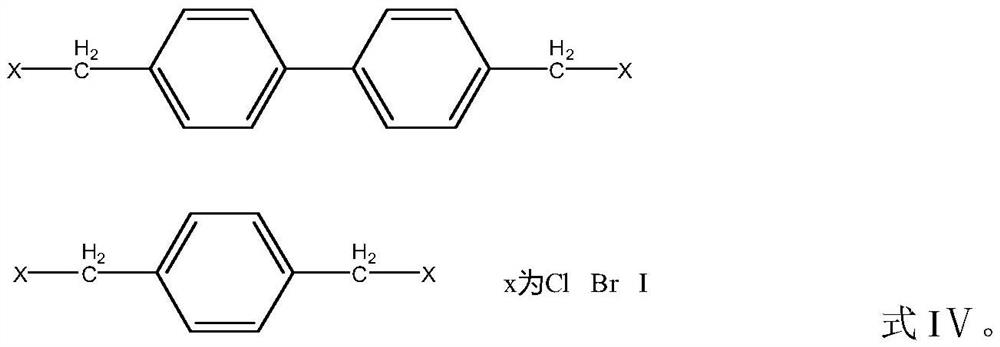

Method used

Image

Examples

Embodiment 1

[0050] Take 940 parts of phenol and 528 parts of dicyclopentadiene (the molar ratio is 1:0.4), add 18.8 parts of sulfonic acid resin as a catalyst at 100°C, and after 2 hours of reaction, filter out and cool the sulfonic acid resin, and then add 1200 parts of Cardanol (C15 alkylphenol) (the molar ratio to phenol is 1:0.4), warm up to 90°C, slowly add 754 parts of biphenyl dichlorobenzyl (molar ratio to phenol is 0.3) within 2 hours, after the addition is completed, Raise the temperature to 180°C, vacuumize for 1 hour to remove excess phenol, and finally obtain 3303 parts of brown resin with a softening point of 81°C.

Embodiment 2

[0052] Take 940 parts of phenol and 528 parts of dicyclopentadiene (the molar ratio is 1:0.4), add 9.4 parts of catalyst sulfonic acid resin at 90°C, and react for 2 hours, filter out and cool the sulfonic acid resin, and then add 1300 parts Dodecyl (molar ratio to phenol is 1:0.5), heat up to 90°C, slowly add 754 parts of biphenyl benzyl dichloride (molar ratio to phenol is 0.3) within 1 hour, after the addition is complete, heat up to 150°C , evacuated for 3 hours to remove excess phenol, and finally obtained 3351 parts of brown resin, and the softening point of the resin was 71°C.

Embodiment 3

[0054] Take 940 parts of phenol and 528 parts of dicyclopentadiene (the molar ratio is 1:0.4), add 94 parts of catalyst sulfonic acid resin at 120°C, react for 2 hours, filter out and cool the sulfonic acid resin, and then add 1500 parts of tert-butylphenol (molar ratio to phenol is 1:1), heat up to 110°C, slowly add 754 parts of biphenyl dichlorobenzyl (mole ratio to phenol is 0.3) within 3 hours, after the addition is completed, heat up to 190°C, The excess phenol was removed by vacuuming for 1 hour, and finally 3351 parts of brown resin was obtained. The softening point of the resin was 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com