Fluororubber compound, preparation method and application thereof

A technology of fluororubber and compound rubber, which is applied in the field of rubber to achieve the effects of improving elasticity and mechanical properties, low compression set performance, and excellent elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

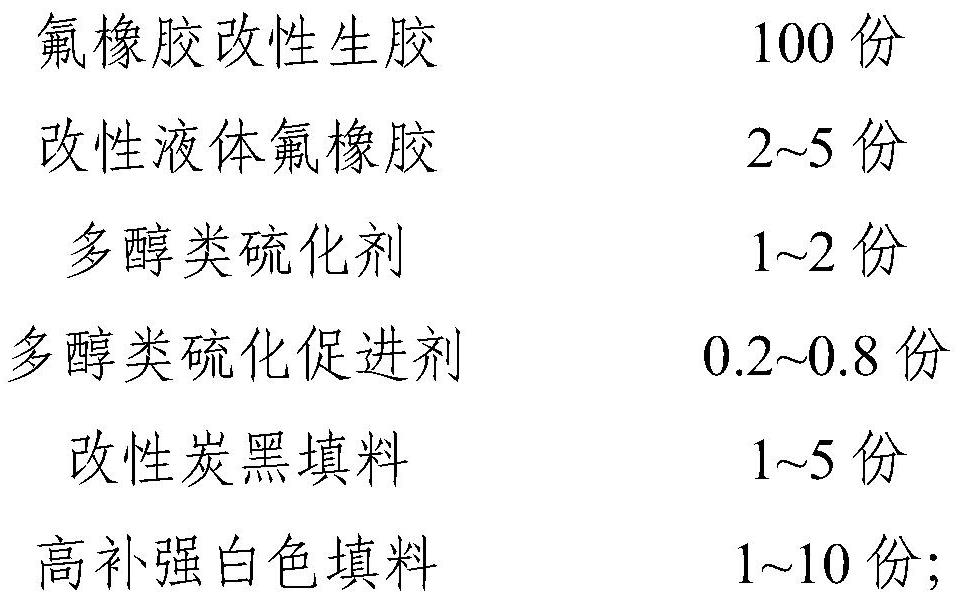

[0052] This embodiment provides a fluorine rubber compound prepared from the following components:

[0053]

[0054]

[0055] The preparation method of the modified N762 carbon black filler is as follows: after mixing the carbon black N762 with 1 to 3% of a four-functional silane coupling agent for 2 hours, and then airtightly storing it for 12 hours;

[0056] The preparation method of described fluororubber compound rubber is as follows:

[0057] (1) According to the formula ratio, bisphenol AF, BPP, CGUF201, magnesium oxide 170, ultrafine calcium hydroxide NICC5000, WS280, and A54 are pre-prepared according to the amount of 10kg of raw rubber per vehicle, and are sealed and mixed in the container to prevent auxiliary Agent failure;

[0058] (2) Shear and mix CGFT600A and FKM26H01M in the state of open kneading, so that the two are evenly kneaded together, parked, and stored in an airtight manner; in the pressurized internal mixer, add raw rubber after mixing Mixing t...

Embodiment 2

[0063] This embodiment provides a fluorine rubber compound prepared from the following components:

[0064]

[0065]

[0066] The preparation method of the modified N762 carbon black filler and the preparation method of the fluorine rubber compound are the same as in Example 1.

Embodiment 3

[0068] This embodiment provides a fluorine rubber compound prepared from the following components:

[0069]

[0070] The preparation method of the modified N762 carbon black filler and the preparation method of the fluorine rubber compound are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com