High-frequency IMPATT diode mesa die structure and preparation method thereof

A diode and mesa technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor reliability, reduce device negative resistance, and reduce RF power efficiency, and increase the heat sink area. , Improve the output power and reduce the effect of additional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

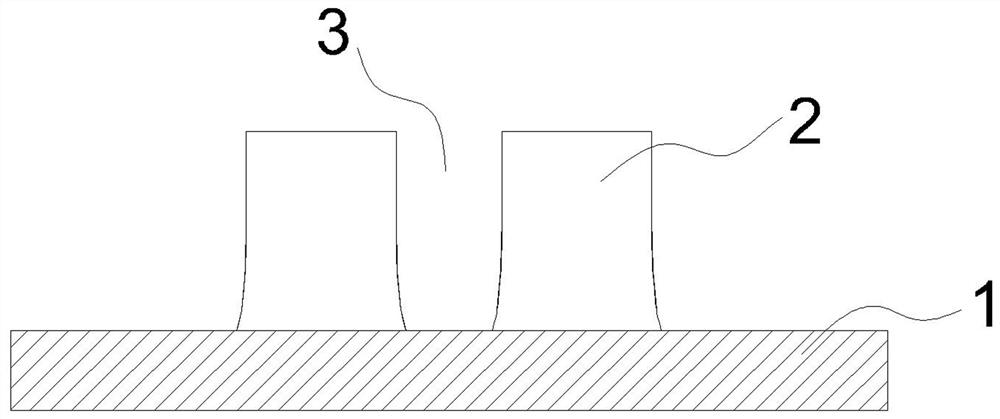

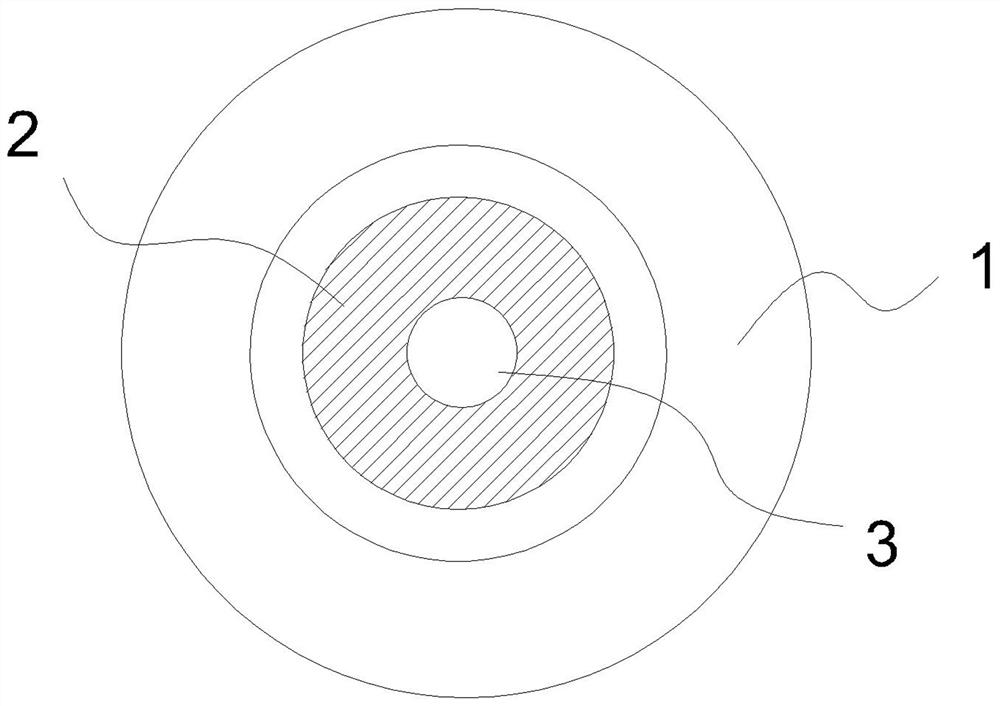

[0025] combine figure 1 and figure 2 As shown, the present invention provides a high-frequency IMPATT diode mesa tube core structure, including a p+ conductive substrate 1, a mesa tube core pn junction 2 is provided on the top surface of the p+ conductive substrate, and a vertical The through hole 3 makes the mesa tube core form a circular frustum shape; the diameter of the lower part of the through hole 3 is tapered from top to bottom.

[0026] The present invention also provides a kind of preparation method of high-frequency IMPATT diode mesa die structure, comprises the following steps:

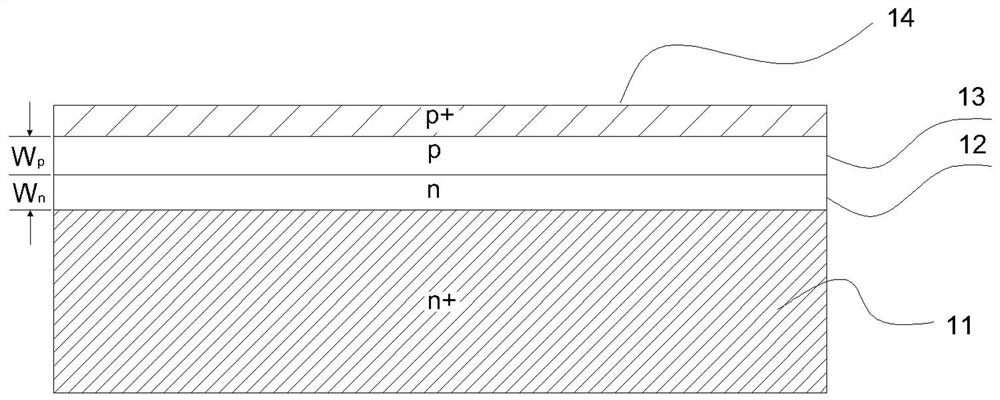

[0027] S1, combine image 3 As shown, an n-type epitaxial layer 12, a p-type epitaxial layer 13 and a p+ epitaxial layer 14 are sequentially grown on an n+ silicon wafer 11;

[0028] The thickness Wn of n-type epitaxial layer 12 is given by the formula (1) decide,

[0029] The thickness Wp of the p-type epitaxial layer 13 is given by the formula (2) decide,

[0030] In formulas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com