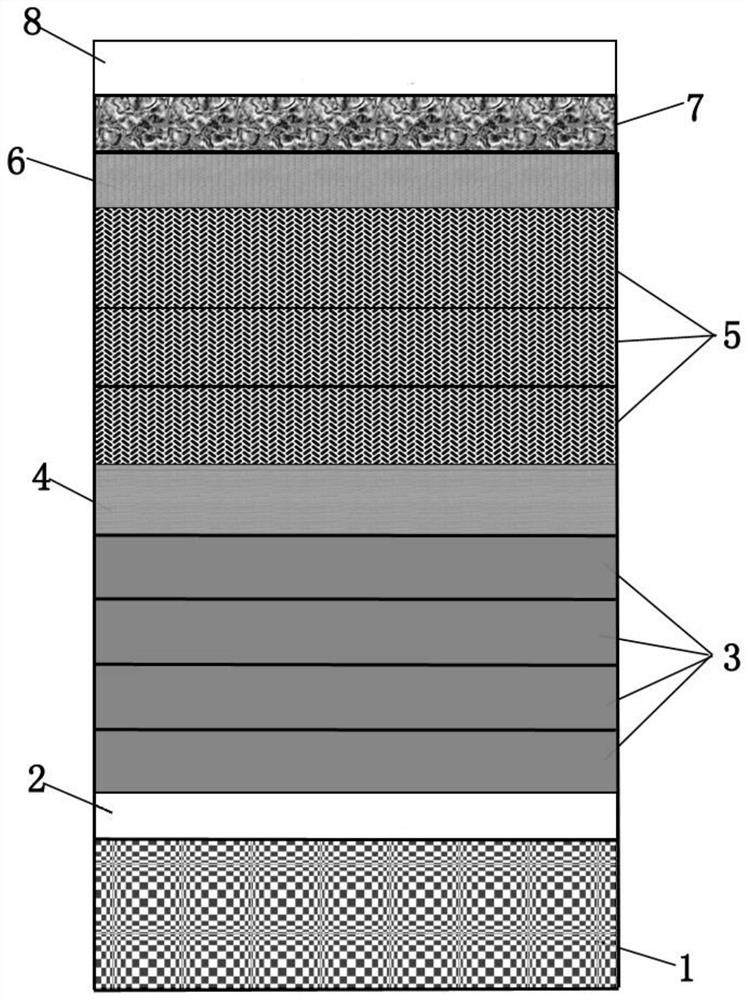

HEMT epitaxial device based on third-generation semiconductor GaN material and growth method thereof

A semiconductor and epitaxy technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of unstable gate voltage pinch-off current characteristics, decreased channel 2DEG mobility, and weakened gate-to-current Control and other issues to achieve the effect of improving I-V characteristics, improving the overall crystal quality, and reducing additional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A HEMT epitaxial device based on the third-generation semiconductor GaN material, using metal organic compound chemical vapor deposition (MOCVD) epitaxial growth technology, using trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum ( TMAl), ammonia (NH 3 ), silane (SiH 4 ) respectively provide the gallium source, indium source, aluminum source, nitrogen source, and silicon source required for growth, with nitrogen and hydrogen as carrier gases;

[0075] (1) Clean the substrate with dilute hydrochloric acid and isopropanol, then rinse with water and dry it, put it into MOCVD equipment and bake at 1200°C for 10 minutes;

[0076] (2) Cool down the equipment to 500°C, pressure 150torr, feed trimethylgallium and ammonia to grow a layer of 10nm GaN, then raise the temperature to 1020°C, pressure 250torr, grow 100nm GaN;

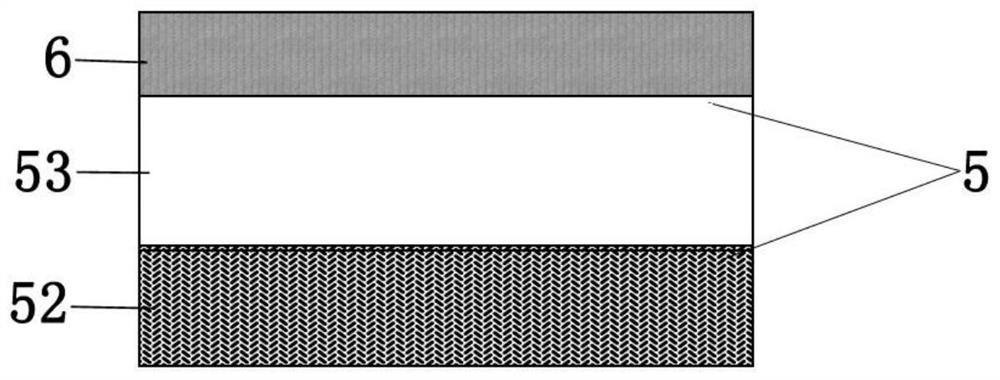

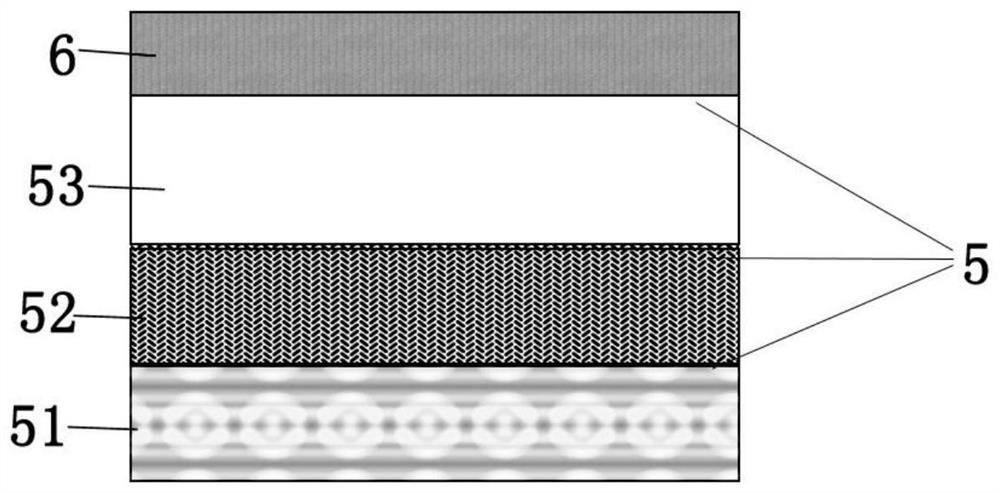

[0077] (3) At 1040°C, with an air pressure of 300torr, inject trimethylaluminum, trimethylgallium and ammonia to grow a layer of 1nm Al 0....

Embodiment 2

[0088] A HEMT epitaxial device based on the third-generation semiconductor GaN material, using metal organic compound chemical vapor deposition (MOCVD) epitaxial growth technology, using trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum ( TMAl), ammonia (NH 3 ), silane (SiH 4 ) respectively provide the gallium source, indium source, aluminum source, nitrogen source, and silicon source required for growth, with nitrogen and hydrogen as carrier gases;

[0089] (1) Clean the substrate with dilute hydrochloric acid and isopropanol, then rinse with water and dry it, put it into MOCVD equipment and bake at 1200°C for 10 minutes;

[0090] (2) Cool down the equipment to 500°C, air pressure 150torr, feed trimethylgallium and ammonia gas to grow a layer of 20nm GaN, then raise the temperature to 1020°C, air pressure 250torr, grow 200nm GaN;

[0091] (3) At 1040°C, with an air pressure of 300torr, inject trimethylaluminum, trimethylgallium and ammonia to grow a layer o...

Embodiment 3

[0102] A HEMT epitaxial device based on the third-generation semiconductor GaN material, using metal organic compound chemical vapor deposition (MOCVD) epitaxial growth technology, using trimethylgallium (TMGa), trimethylindium (TMIn), trimethylaluminum ( TMAl), ammonia (NH 3 ), silane (SiH 4 ) respectively provide the gallium source, indium source, aluminum source, nitrogen source, and silicon source required for growth, with nitrogen and hydrogen as carrier gases;

[0103] (1) Clean the substrate with dilute hydrochloric acid and isopropanol, then rinse with water and dry it, put it into MOCVD equipment and bake at 1200°C for 10 minutes;

[0104] (2) Cool down the equipment to 500°C, air pressure 150torr, feed trimethylgallium and ammonia gas to grow a layer of 12nm GaN, then raise the temperature to 1020°C, air pressure 250torr, grow 150nm GaN;

[0105] (3) At 1040°C, with an air pressure of 300torr, inject trimethylaluminum, trimethylgallium and ammonia to grow a layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com